A universal feed port connection structure and disassembly method

A connection structure and material port technology, which is used in transportation and packaging, freight vehicles, oil tankers, etc., can solve the problems of affecting the connection stability, destroying the liner, and the rotation of the external thread sleeve, and improving the connection stability. The effect of improving the sealing strength and avoiding damage to the liner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

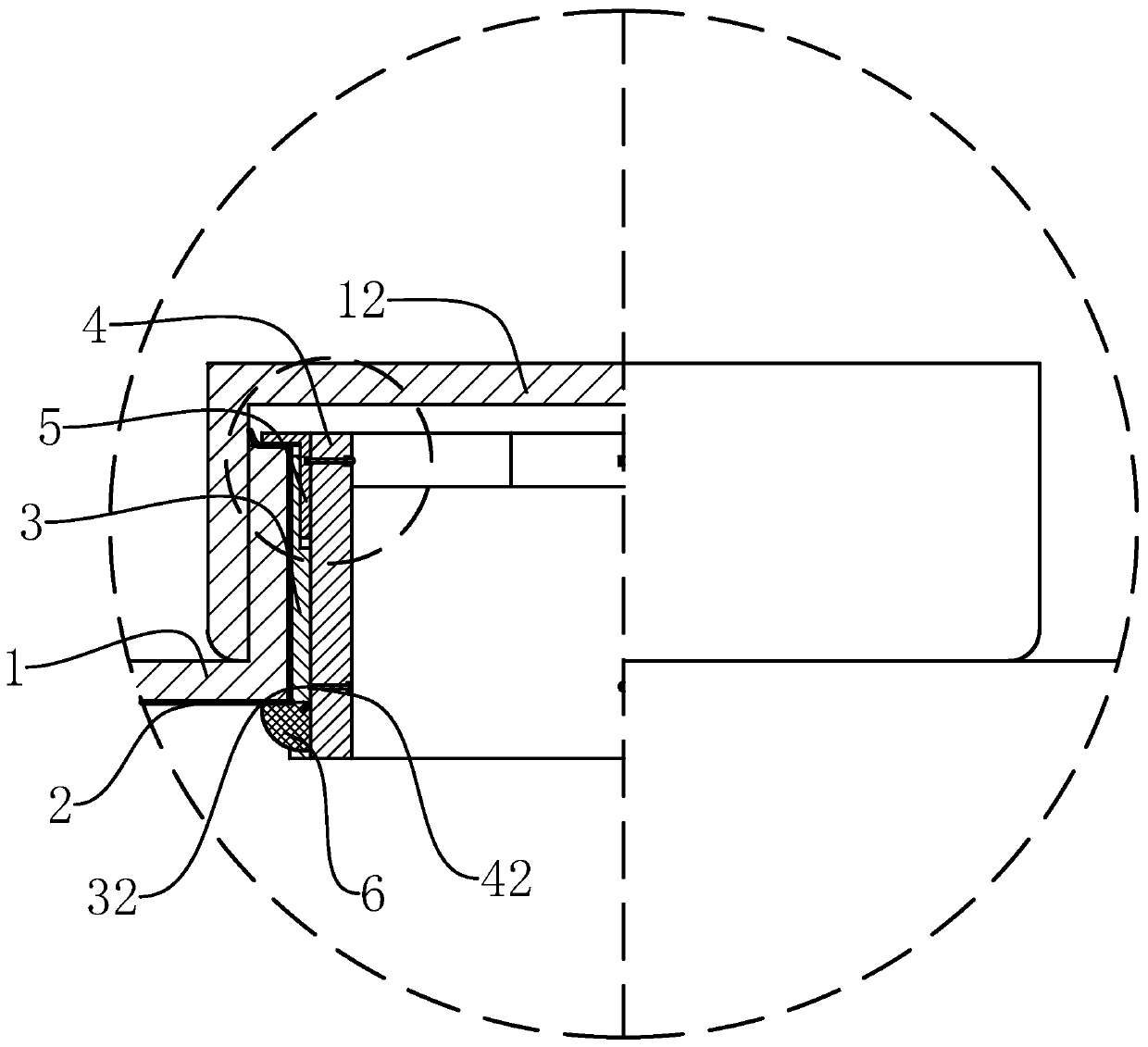

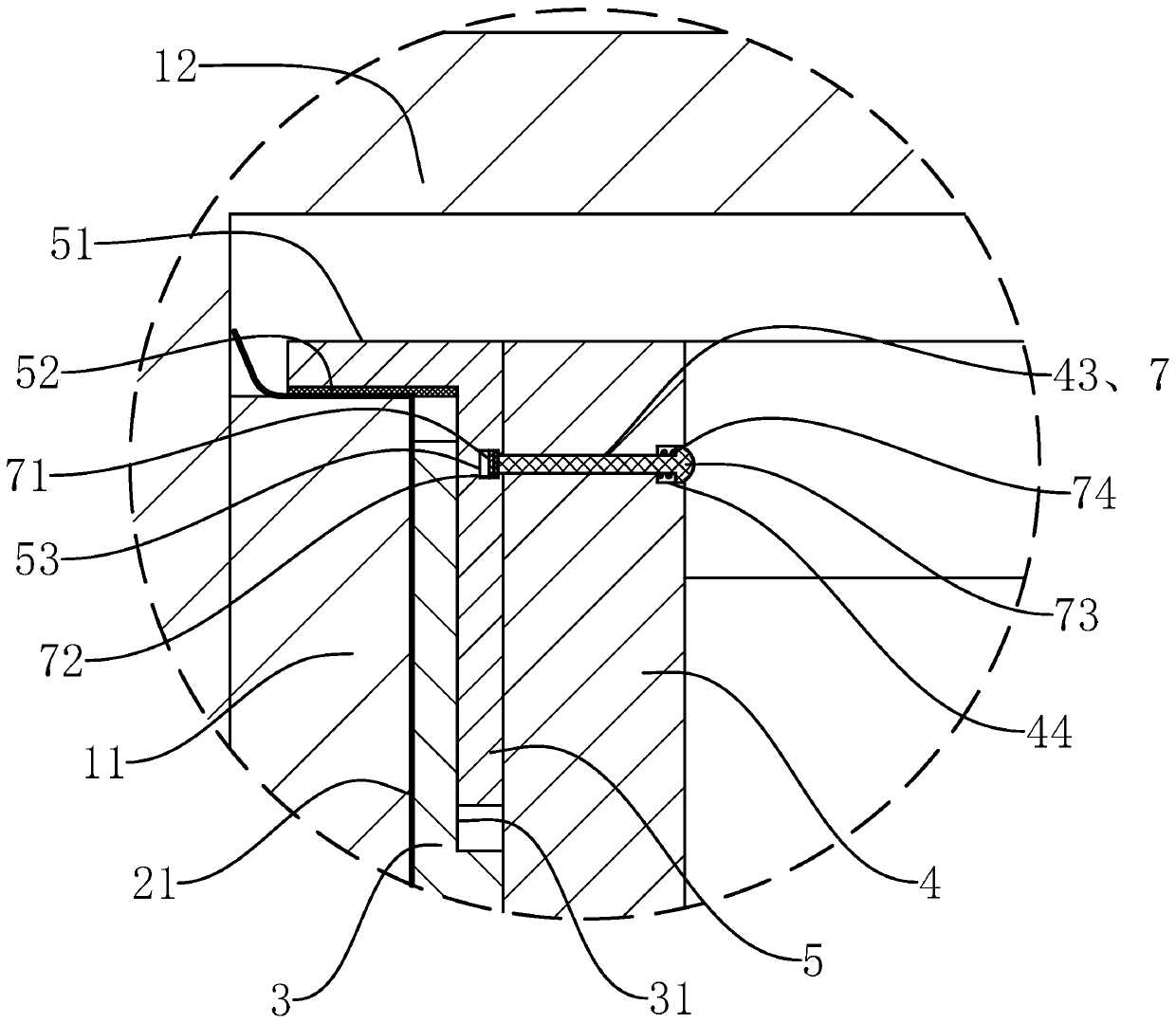

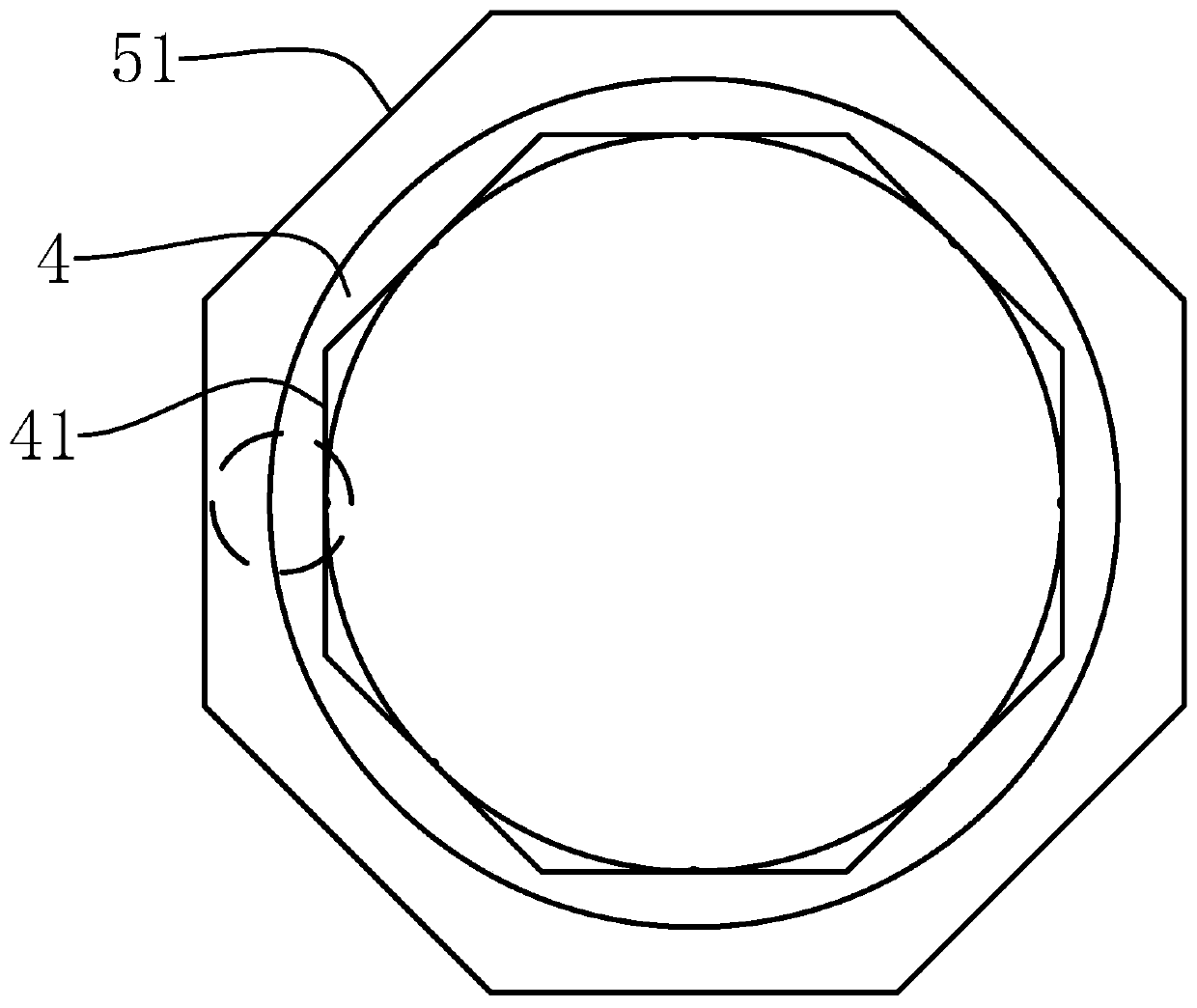

[0051] like Figure 1-9 As shown, the present invention is a universal feed port connection structure, including the inlet and outlet barrel 11 whose bottom end is fixed to the outer wall of the carriage 1, the bottom end of the inlet and outlet barrel 11 communicates with the interior of the carriage 1, and the top of the inlet and outlet barrel 11 is detachably fixed with a cylinder cover 12. It also includes a liquid bag 2 with a material inlet and outlet. The inlet and outlet of the liquid bag 2 is connected with a soft liner 21. The liner 21 is expanded into a cylindrical structure, and it also includes a mouth opening device. The mouth opening device includes a sleeve The support sleeve 3, the adjustment sleeve 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com