Material distributing mechanism of automatic cable tie tool

A material-distributing mechanism and tool technology, applied in packaging automatic control, packaging, packaging protection, etc., can solve the problems of rough feeding method, error-prone, low efficiency, etc., and achieve the effect of outstanding cable tie processing ability and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

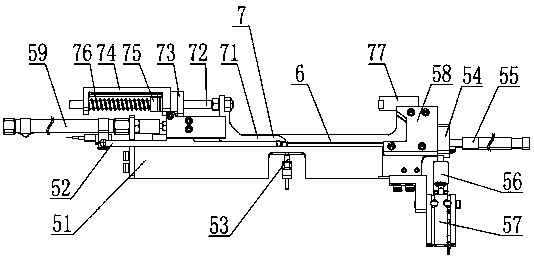

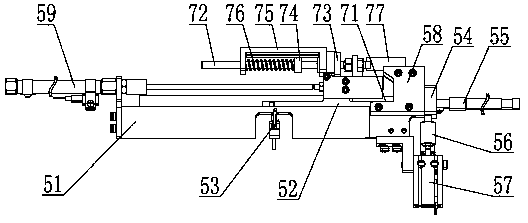

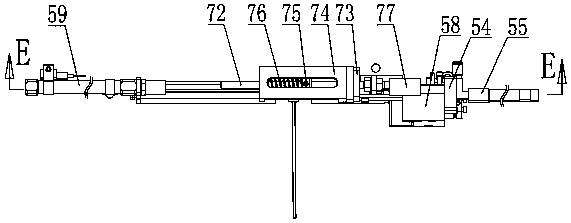

[0028] Such as Figure 1 to Figure 4 As shown, a material distributing mechanism of an automatic cable tie tool includes: a material distributing body 51, a material distributing rod 52, a guide block 58, and an elastic pressure plate system 7; it also includes: a sensor 53, a valve seat 54, a valve 56, a valve Cylinder 57, square cross-section feed pipe 55; there are steps on the material distribution body 51, the bottom surface of the step of the material distribution body 51 is aligned with the bottom surface of the output guide rail of the circular vibrating plate 4, from the circular vibrating plate The cable tie output by the linear guide rail of 4 just transitions to the step of the distribution body 51, and the step width of the distribution body 51 can just accommodate a head of a cable tie, and the distribution rod 52 is also installed on the distribution body 51. On the step of the material body 51, the end of the distribution rod 52 is close to the head of the tie ...

Embodiment 2

[0032] Such as Figure 1 to Figure 8 As shown, the square-section feeding pipe 55 means that the cross-section of its inner hole is square. The tube 55 is made of soft material; when "a material distribution mechanism for an automatic cable tie tool" is used in conjunction with a fixed automatic cable tie tool, the square-section feeding tube 55 is made of a soft material or a hard material .

Embodiment 3

[0034] Such as Figure 9 As shown, the material distributing mechanism of a kind of automatic cable tie tool is used for automatic counting of quantitative packaging of cable ties, and the valve seat 54, valve 56, square section feeding pipe 55 are canceled, and the material distribution rod 52 After the cable tie is pushed out and dropped into the material receiving container 10, the control processor 2 automatically calculates that the cable tie released by the material distribution rod 52 reaches the set number and enters the next working cycle; of course, if the valve seat 54 is kept , valve 56, square cross-section feeding pipe 55, also does not affect the material distributing mechanism of a kind of automatic cable tie tool described as the automatic counting device of quantitative packing of cable tie; The valve seat 54 slides and is connected with the material distribution body 51 in turn in turn, so that it can be realized that one "a material distribution mechanism o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com