Automatic shaping and wrapping device for damping block

A damping block and wrapping technology is applied in the field of damping block automatic shaping and wrapping devices, which can solve the problems of position deviation, manual fatigue, unsightly appearance, etc., and achieve the effects of improving efficiency and reliability, reducing production costs and saving manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

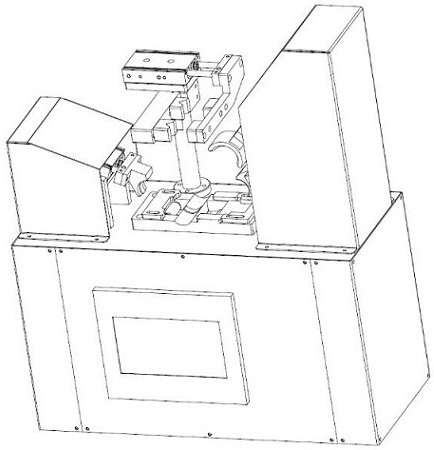

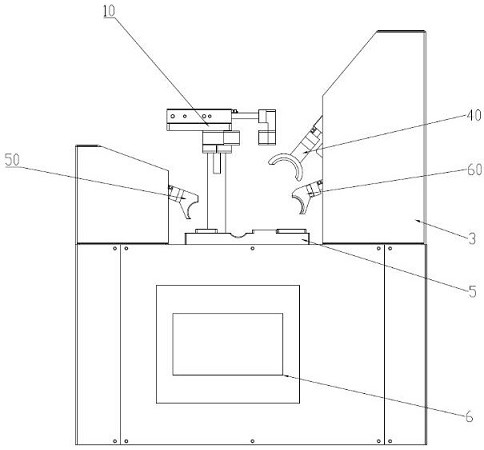

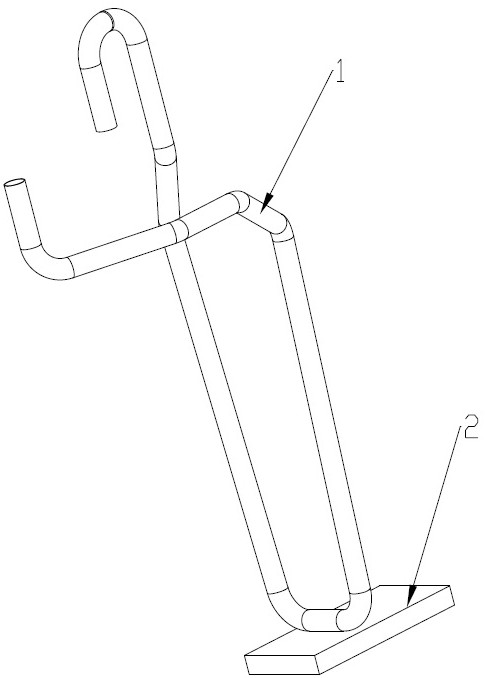

[0038] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0039] like Figure 1 to 8As shown, the rack level mounting platform 31 is mounted on the accessory support device 32 of the host frame 3. The carrier 5 opens a square hole and a radical arc of the shaped and its positioning square for damping block 2. The damping block 2 is placed in the positioning square groove of the carrier 5. The fixed pre-clamping device 102 in the copper tube clamping device 10 is mounted with a small member having a pre-pressure such as a plunger screw or a spring device, and the copper tube 1 is placed in the fixed pre-clamping device 102, it can be positioned. The wrapping position of the copper tube 1 is located in the middle of the damper 2 (or on the right side, only the rear relevant mechanism can be changed), and the initial state see Figure 4 , Figure 4A Down; foot switch or hands simultaneously press the start button, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com