Automatic cutting, feeding and counting device for connected ribbons

A conjoined and automatic technology, which is applied in the direction of binding materials, automatic control of packaging, and parts of binding machinery, etc., can solve the problems of error-prone, easy-to-deform bulk ties, and low efficiency, so as to achieve no vibration noise, high efficiency, The effect of high operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

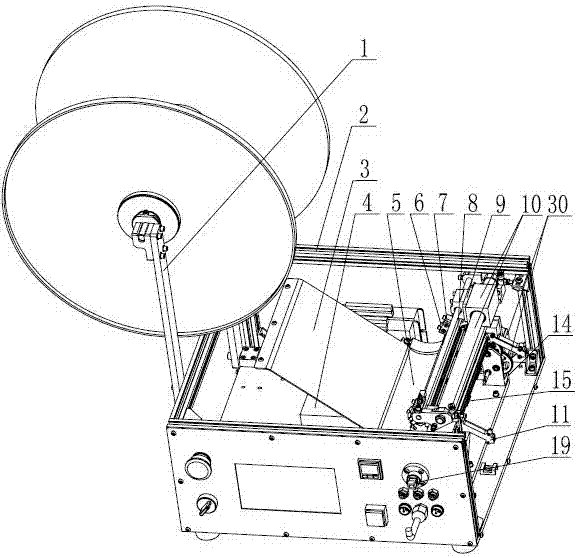

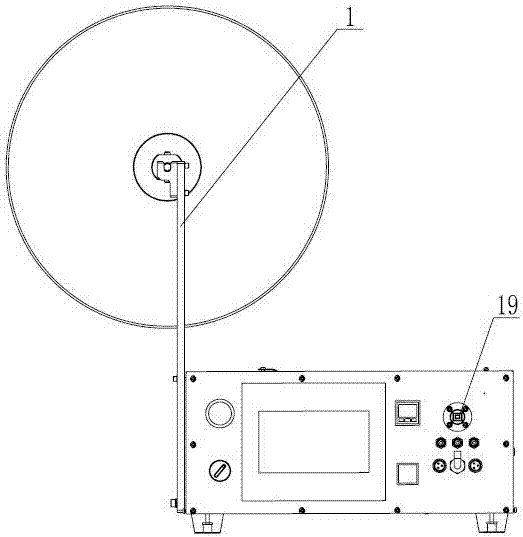

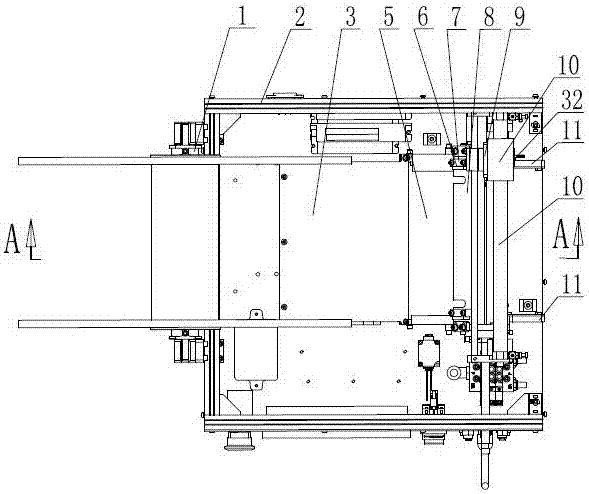

[0038] Such as Figure 1 to Figure 24 As shown, a device for automatic material cutting, feeding and counting of one-piece cable ties, including: main frame 2, cable tie bracket 1, material guide plate 3, guide arc 5, control processor 4, cable tie pressing plate 8. Blade 6, blade seat 7, indexing roller 15, indexing mechanism 30, bracket plate 14, pusher block 9, pusher cylinder 10, valve seat 16, valve 17, valve cylinder 18, square section feeding pipe 19 ; The indexing mechanism 30 can make the indexing roller 15 perform intermittent indexing movement, and the indexing mechanism 30 is made up of a motor 31, a sensor 34, a gear 32, a central gear 33, and an induction plate 35, and the central gear 33 is coaxially connected with the indexing roller 15, the induction plate 35 is coaxially connected with the motor 31, and the power of the motor 31 drives the central gear 33 and As for the indexing roller 15, when the motor 31 rotates one revolution, the indexing roller 15 rota...

Embodiment 2

[0041] The structure described in Embodiment 1 is based on the situation that a cable tie 61 is sent out at a time, as Figure 9 , Figure 10 , Figure 11 Among them, if two or more cable ties 61 are to be sent out each time, then: two or more pusher blocks 9, two or more valve seat passages, two or more square-section feeding pipes 19, The indexing roller 15 rotates two or more pitches between the axial grooves at a time, and pushes out two cable ties 61 or a plurality of cable ties 61 each time, so that an automatic material cutting and feeding device can be realized to cooperate with two or more cable ties. An automatic cable tie tool is used.

Embodiment 3

[0043] The described device for automatic cutting, feeding and counting of one-piece cable ties can be used in conjunction with automatic cable tie tools, and can also be used for automatic counting of quantitative packaging of cable ties, such as Figure 9 , Figure 10 , Figure 11 Among them, the configuration of the valve seat 16, the valve 17, and the square-section feeding pipe 19 is based on the fact that a device for automatic cutting, feeding and counting of one-piece cable ties is used in conjunction with an automatic cable tie tool, if the A kind of automatic material cutting, feeding and counting device for one-piece cable ties is used for automatic counting of quantitative packaging of cable ties, so the valve seat 16, valve 17, and square-section feeding pipe 19 are not needed. The pushing block 9 pushes out the cable tie 61 and drops it into the material receiving container, and the control processor 4 automatically calculates the number of axial grooves that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com