Germ-repellent elastomer

A biodegradable, polymer technology, used in the polymer field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] In the preparation methods described herein, the steps may be performed in any order without departing from the principle of the invention, except when the time or operation sequence is explicitly stated. Recitation in a claim that a step is first performed, followed by several other steps, shall be construed to mean that the first step is performed before any other steps, but that the other steps may be performed in any suitable order unless further The sequence is described. For example, a claim element that recites "step A, step B, step C, step D, and step E" should be interpreted to mean that step A is performed first, and step E is performed last, and that steps B, C, and D can be performed in step A and E in any order that still falls within the literal scope of the claimed method. A given step or a subset of steps may also be repeated.

[0013] Furthermore, specified steps may be performed simultaneously unless the claim recitation explicitly recites that they ...

specific Embodiment approach

[0019] The following examples illustrate the invention in more detail.

Embodiment 1

[0022] Example 1 - Selection of mechanical property modifiers:

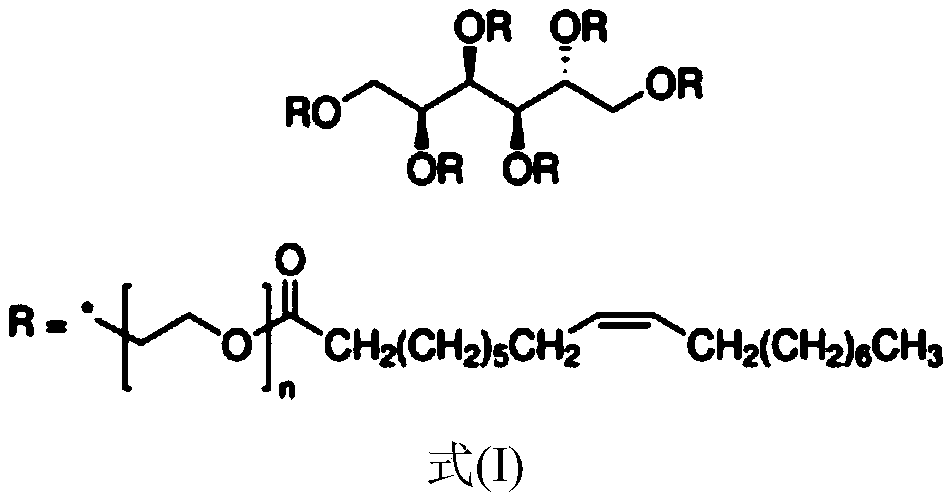

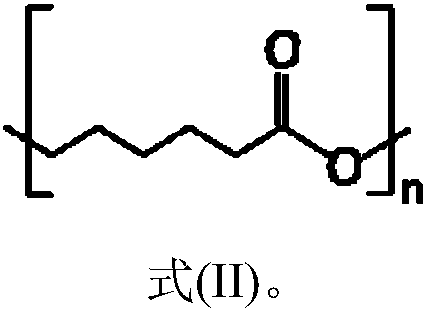

[0023] A range of reagents and modifying compounds were investigated for their ability to modify mechanical properties, such as elongation at break and tensile strength upon incorporation into biodegradable polymers such as polylactic acid (PLA)-based polymers. First, choose As a PLA-based polymer, it can be easily applied in industrial processes because of its injection molding-grade properties. Polyethylene glycol sorbitan hexaoleate (PEG-SHO) represented by formula (I) and polycaprolactone (PCL) represented by formula (II) were selected as the PLA-based biodegradable polymer of the present invention. Modifiers for mechanical properties of substances:

[0024]

[0025]

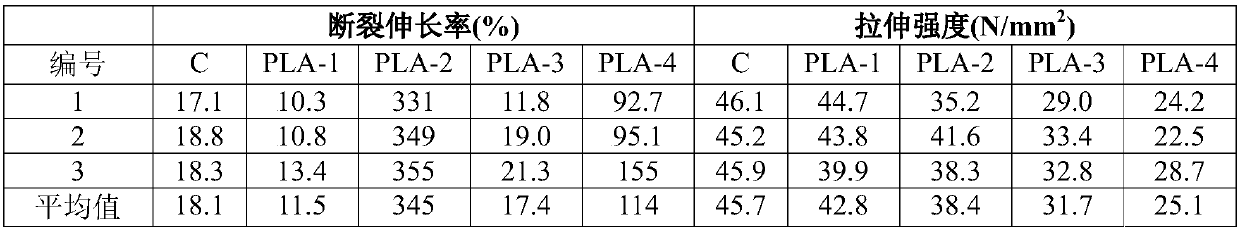

[0026] The effect of their modification on PLA was investigated by comparing the tensile properties of PEG-SHO and PCL before and after modification. V-type specimens (ISO 527) were obtained by injection molding of modified and origin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com