A nickel-plated protective fixture

A technology for protecting fixtures and nickel plating, applied in electrolytic components, electrolytic processes, etc., can solve problems such as scrap, poor nickel layer quality, and nitrogen leakage from parts, and achieve the effect of increasing electroplating area, increasing diversity, and preventing slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

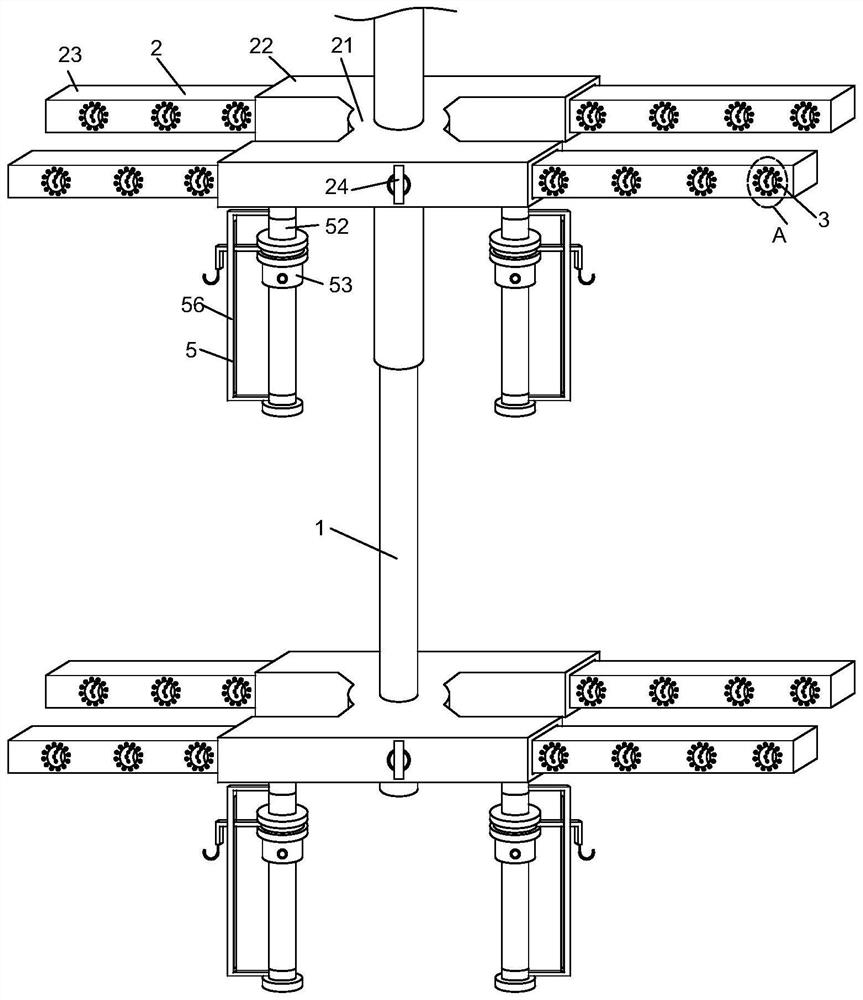

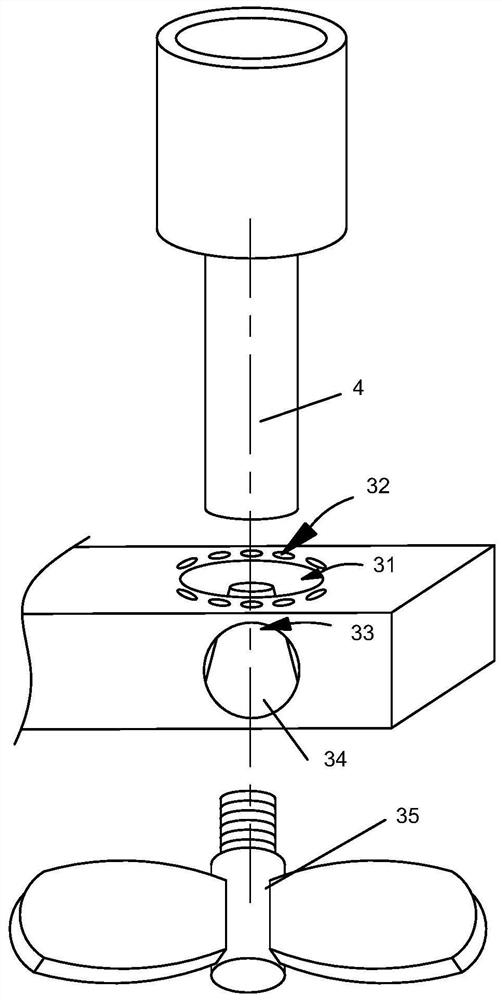

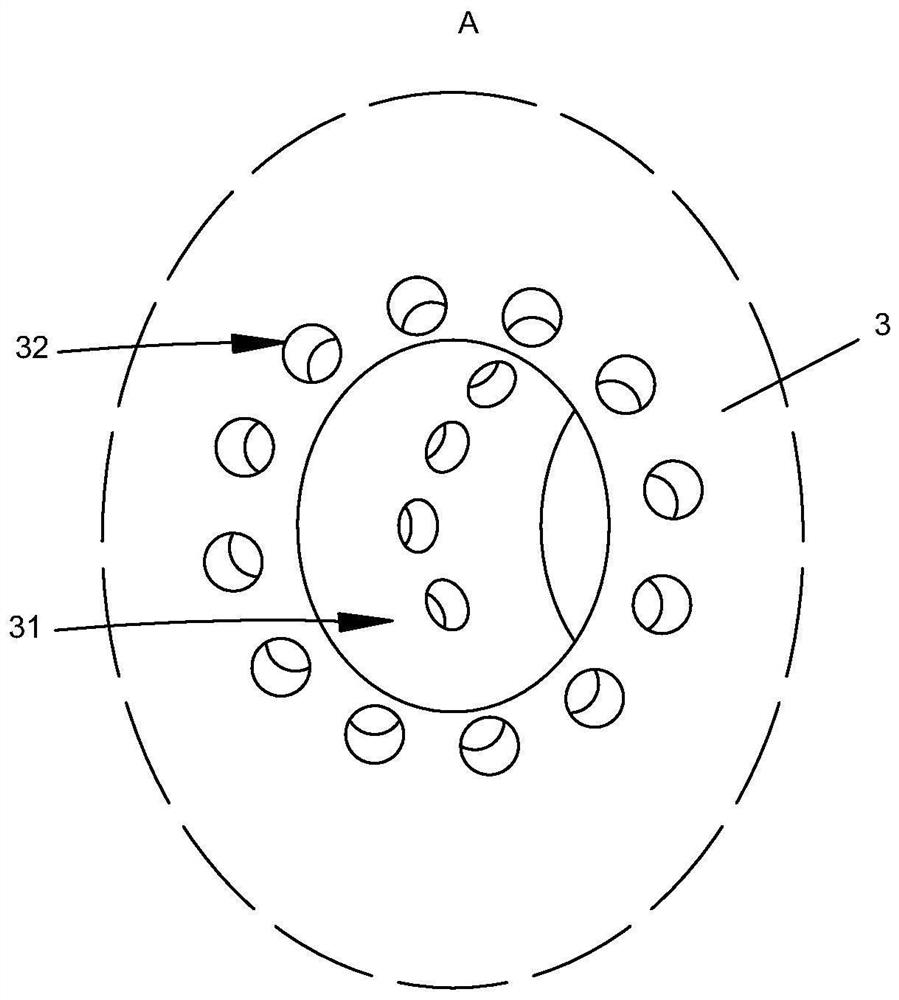

[0021] Please refer to Figure 1-6 As shown, a nickel-plated protective fixture includes a conductive rod 1, an adjuster 2, a snap-in mechanism 3 and a hook mechanism 5. Two regulators 2 with the same specifications are installed on the conductive rod 1, and one of the adjustable The fixed collar 21 in the regulator 2 is fixedly sleeved on the conductive rod 1 near the top of the rod 15-18cm, and the fixed collar 21 in the other regulator 2 is fixedly sleeved on the conductive rod 1 near the bottom of the rod 2- 3cm, the regulator 2 includes a fixed collar 21, a square through pipe 22, a support rod 23 and a first thumb screw 24, and the two side walls of the fixed collar 21 are fixedly installed with a horizontally arranged square through pipe 22, and two square through pipes 22 are symmetrically distributed, and a support rod 23 for sliding connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com