High-modulus high-gram-weight glass fiber fabric TLX1350

A glass fiber and high modulus technology, applied in fabrics, multi-strand fabrics, textiles, etc., can solve the problems of host overload, heavy blades, and unsatisfactory tensile properties, so as to improve tensile properties, reduce the number of laying layers, The effect of improving the soaking effect

Pending Publication Date: 2020-01-17

ZHEJIANG HENGSHI FIBER FOUND CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, the normal modulus of blade shell reinforcement materials commonly used in the industry cannot meet the tensile properties required for the design of super-large offshore blades. Increasing the layup and increasing the thickness of FRP to increase the strength of the blade will cause the blade to be overweight. risk of overload

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

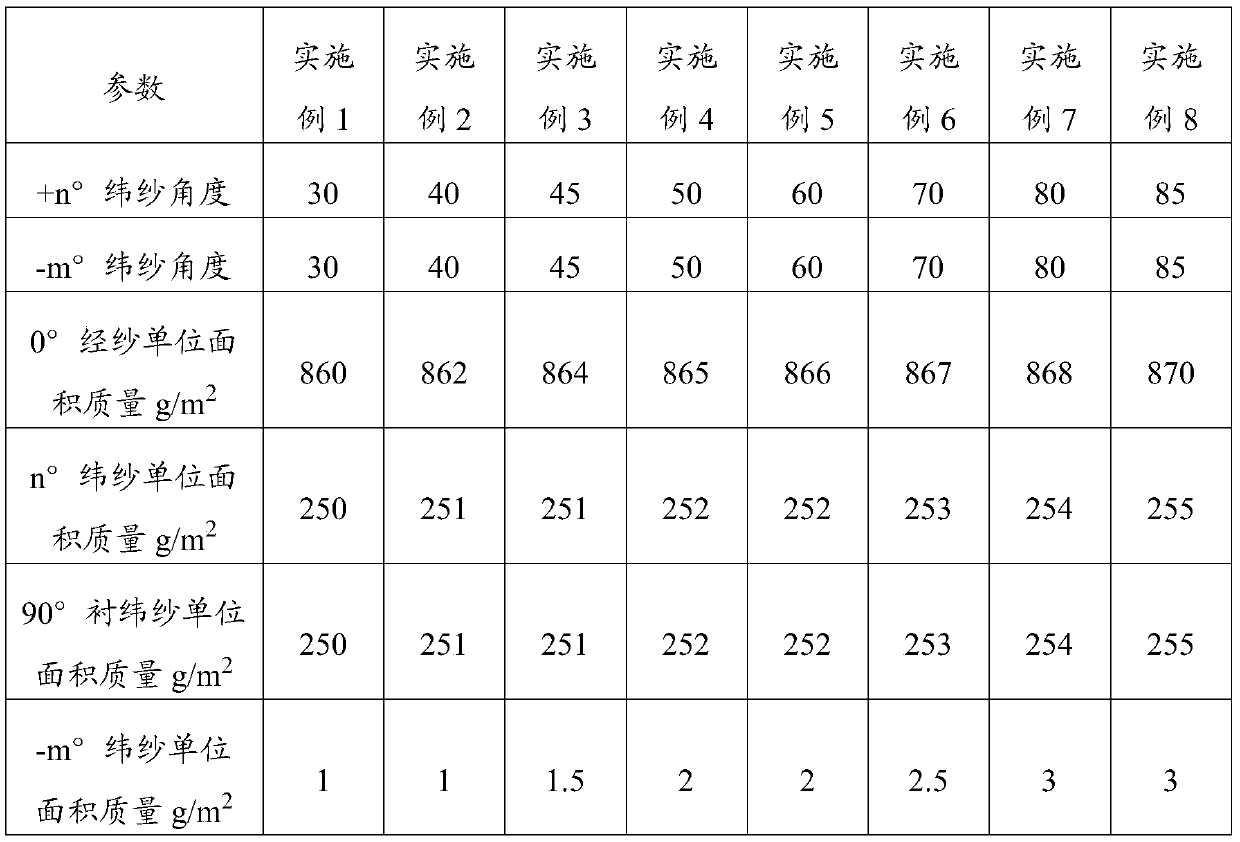

[0032] Table 1 shows some examples of the high modulus and heavy glass fiber fabric TLX1350 of the present invention. It should be pointed out that the high modulus and heavy glass fiber fabric TLX1350 of the present invention is not limited to the data in Table 1.

[0033] Table 1 Example of high modulus and heavy glass fiber fabric TLX1350

[0034]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

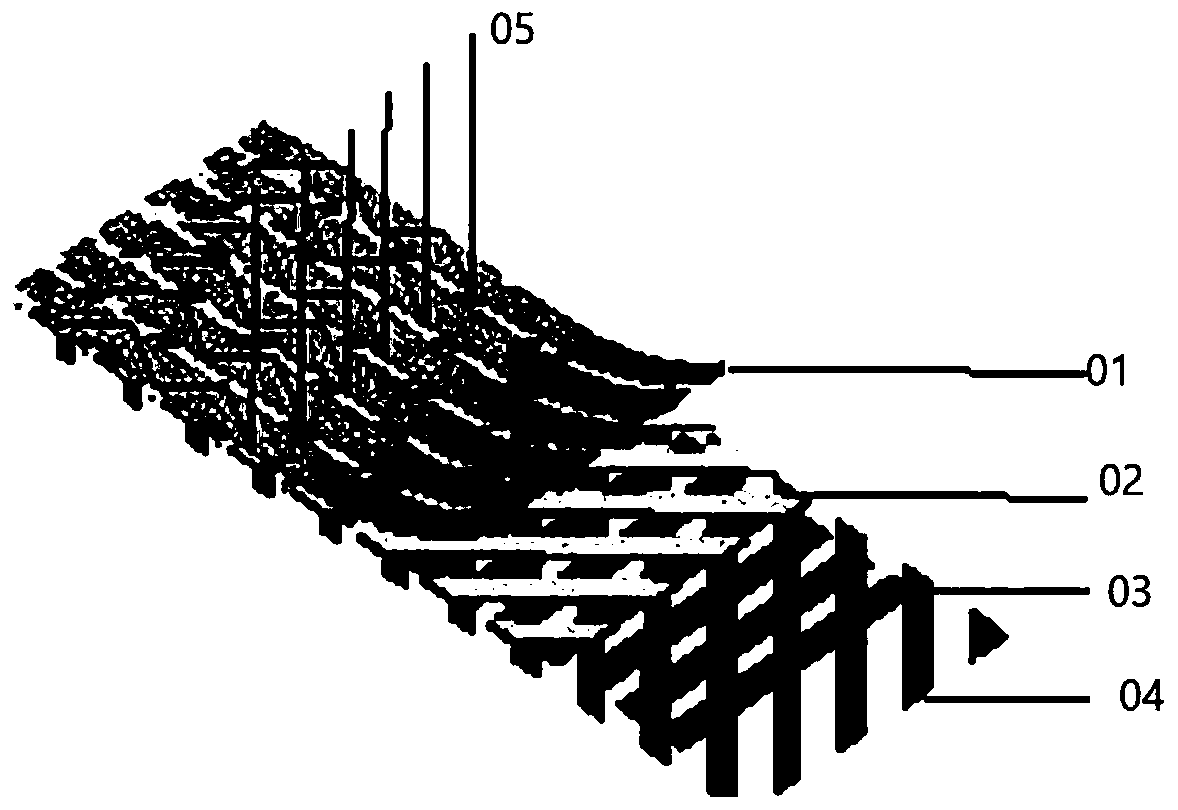

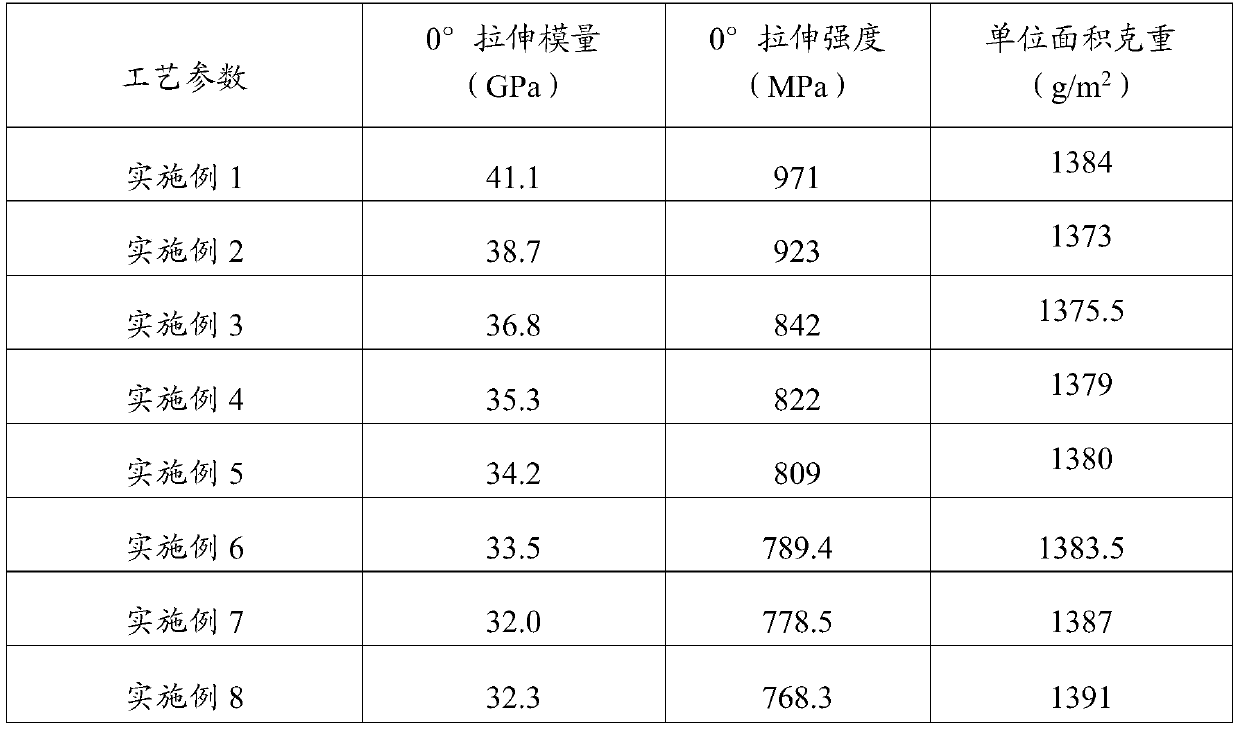

The invention discloses a high-modulus high-gram-weight glass fiber fabric TLX1350, which comprises a warp layer, a first diagonal weft layer, a liner weft layer, a second diagonal weft layer and polyester yarns in sequence from top to bottom. The polyester yarns are used for binding of the warp layer, the first diagonal weft layer, the liner weft layer and the second diagonal weft layer. Comparedwith an existing conventional fabric, the high-modulus high-gram-weight glass fiber fabric TLX1350 has advantages that the tensile modulus is increased to 35-45GPa and increased by 25-35%, the tensile strength is improved to 900-1000MPa and increased by 30-40%, and the gram weight in unit area is increased from 1215g / m<2> to 1350g / m<2> and increased by 11%.

Description

technical field [0001] The invention relates to the field of glass fiber products, in particular to a high-modulus and heavy-weight glass fiber fabric for reinforcing wind power blades and a preparation method thereof. Background technique [0002] As a kind of clean and renewable energy, wind energy is close to the bottleneck in the development of land-based wind resources, and people turn their attention to the vast sea area. In the past two years, with the continuous launch of offshore wind turbines by various mainstream machine manufacturers and the increasing number of offshore wind power projects, offshore wind power has become the general trend of wind power development. [0003] Although my country has made many achievements in the development of offshore wind power, there are still many problems and shortcomings in general. As far as blades are the most important large parts of wind turbines, the development of offshore wind power requires the manufacture of suppor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D03D11/00D03D13/00D03D15/00D03D15/08D03D15/56

CPCD03D11/00D03D13/002D03D15/00D10B2101/06D10B2331/04D03D15/267D03D15/56

Inventor 刘召军张健侃余万平章平

Owner ZHEJIANG HENGSHI FIBER FOUND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com