Active oil-gas separator

An oil-gas separator, active technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of insufficient oil-gas separation, poor separation effect, etc., and achieve good effect of oil-gas separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

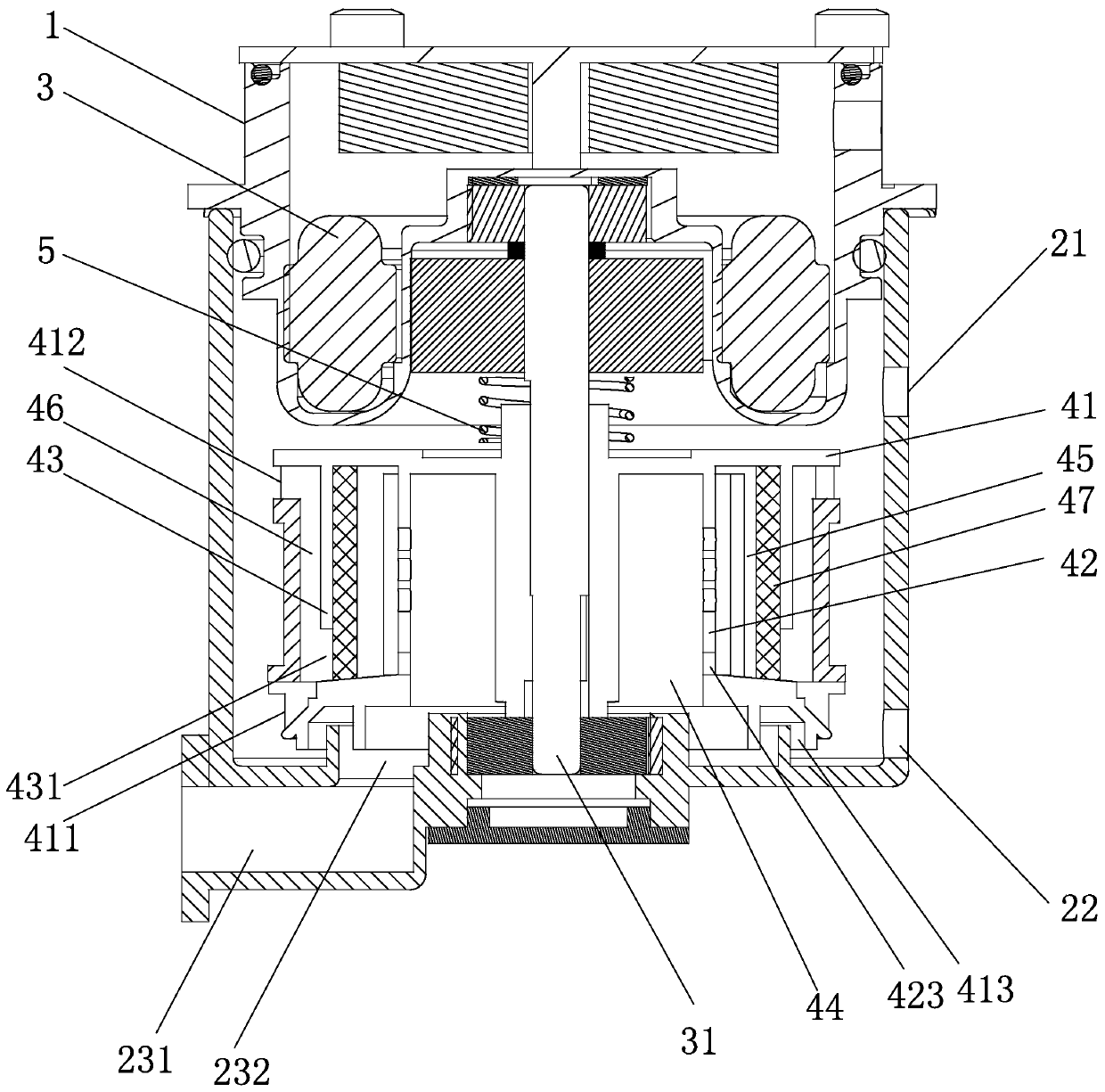

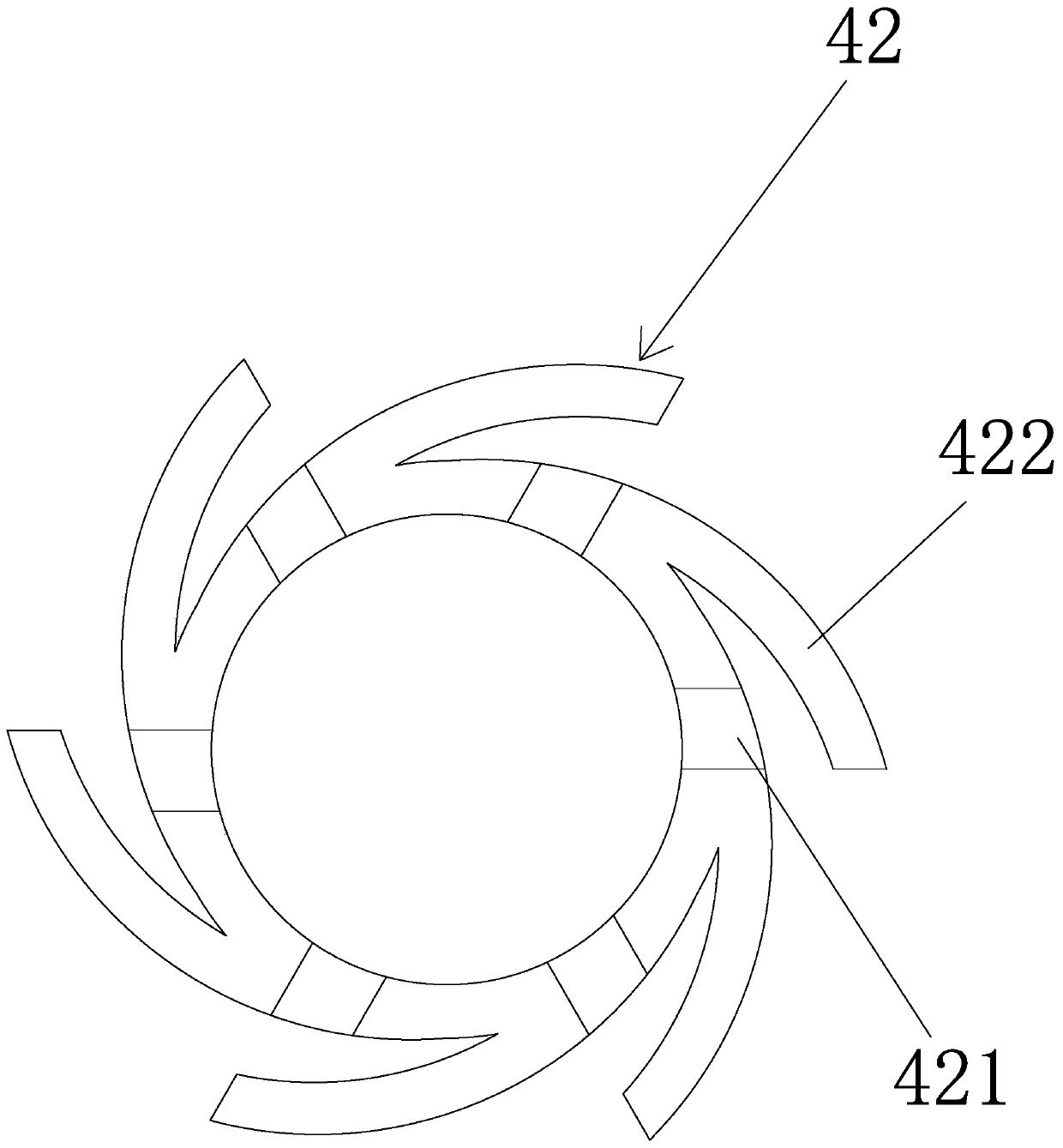

[0034] Embodiment 1: a kind of active oil-gas separator, such as Figure 1 to Figure 2 As shown, it includes an upper casing 1, a lower casing 2 provided with an exhaust port 21 and an oil discharge port 22, a motor 3 installed in the upper casing, and a separation device 4 fixedly connected to the output shaft 31 of the motor. The separation device Including the separation device housing 41, the separation device housing is provided with an air outlet 411 on its upper part and an oil outlet 412 on its lower part, and a first separator 42 with a vent hole is arranged inside the separation device housing from inside to outside And the second partition 43, the first partition and the second partition divide the inside of the separation device housing from inside to outside into the first chamber 44, the second chamber 45 and the third chamber 46, the first partition The lower end is provided with an oil discharge hole 423, the inner bottom surface of the separation device housin...

Embodiment 2

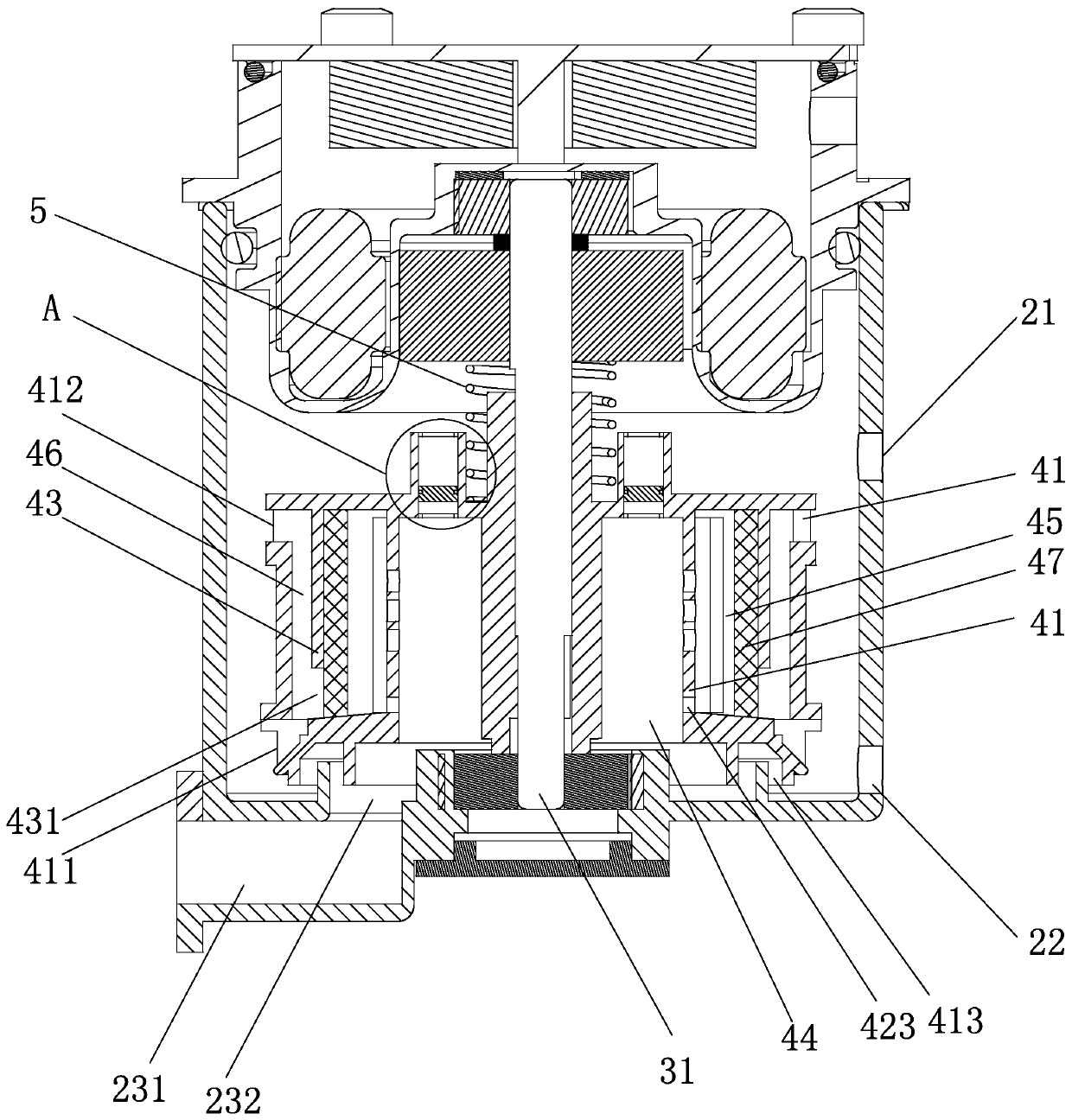

[0039] Embodiment 2, the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

[0040] Such as image 3 and Figure 4 As shown, above the first cavity is provided with an adjustment cavity 6 for adjusting the air pressure in the first cavity. When the air pressure in the first cavity is greater than the preset value, within the adjustment range of the adjustment cavity, the adjustment cavity and the second cavity The volume connected to the first cavity increases, and when the air pressure in the first cavity is lower than a preset value, the volume connected to the first cavity decreases within the adjustment range of the adjustment cavity.

[0041] Specifically, the adjustment chamber includes an adjustment chamber wall 62 formed by extending upward from the housing of the separation device, a floating adjustment plate 61 sliding up and down along the adjustment chamber wall, and a regulating valve for connecting the first chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com