Differential pressure adjusting device of residual mist recovery system and oil mist lubrication system

A technology of recovery system and adjustment device, applied in the direction of engine lubrication, lubricating parts, chemical instruments and methods, etc., can solve the problems such as the influence of the upstream engine pump lubrication, the destruction of the micro-positive pressure of the bearing box, and the large consumption of instrument air. Achieve the effect of good oil and gas separation and reduce maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Through the following description of the embodiments, it will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solutions of the present invention, any components or technical features Changes to the definition and / or formal but not substantive changes to the overall structure should be regarded as the scope of protection defined by the technical solutions of the present invention.

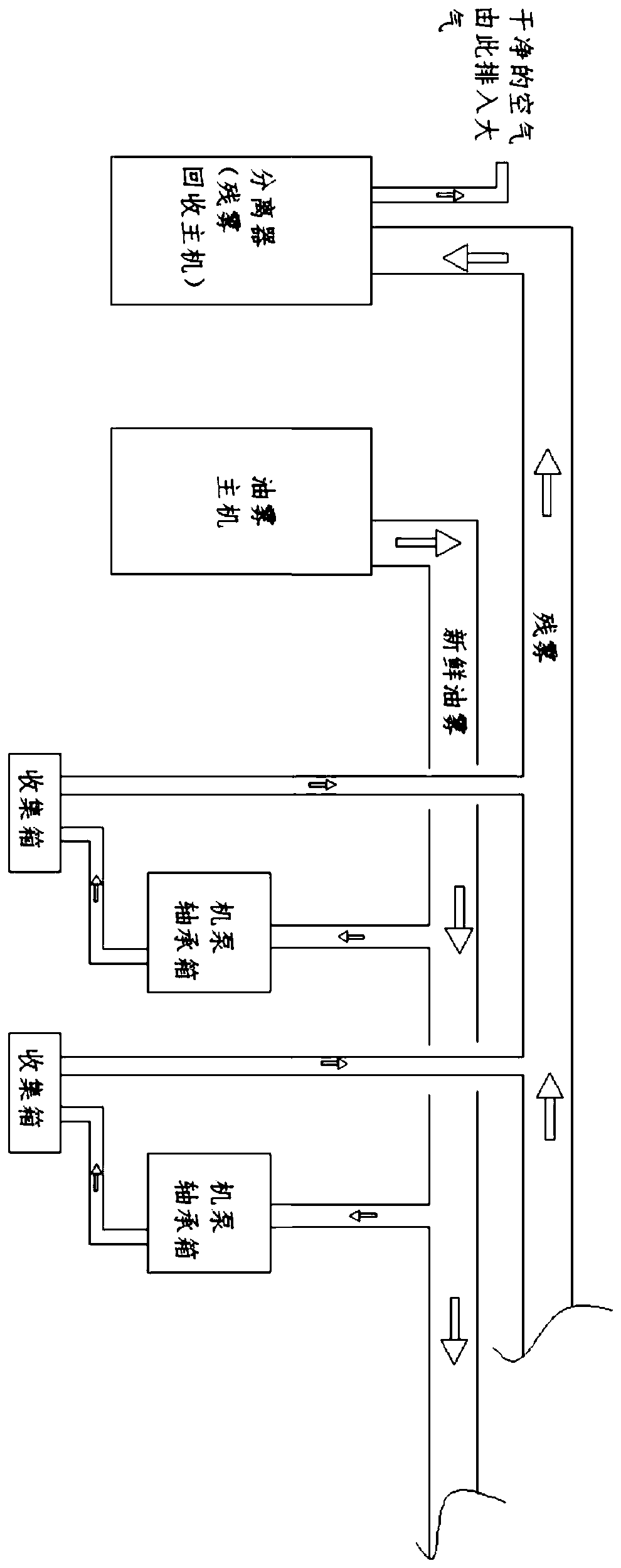

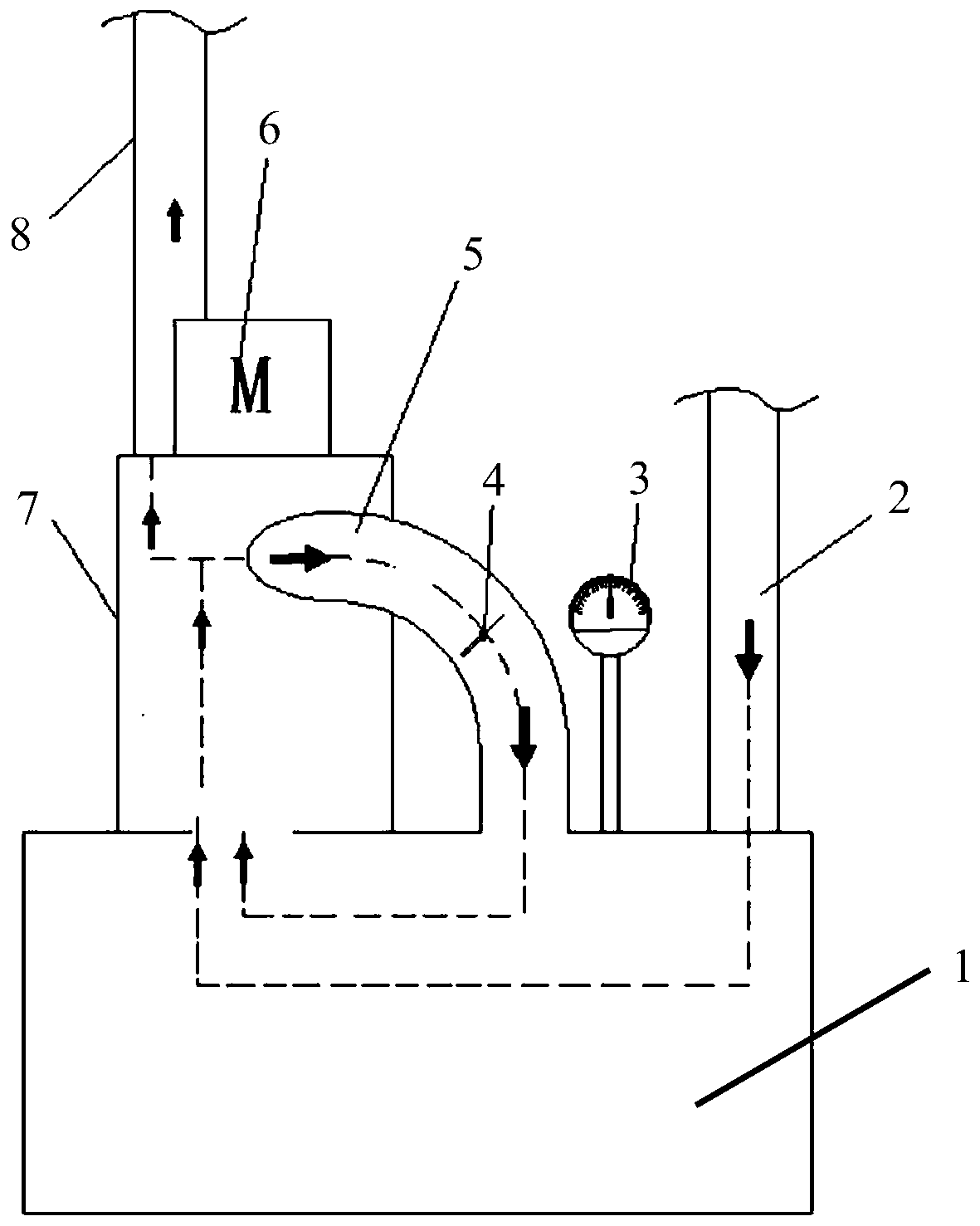

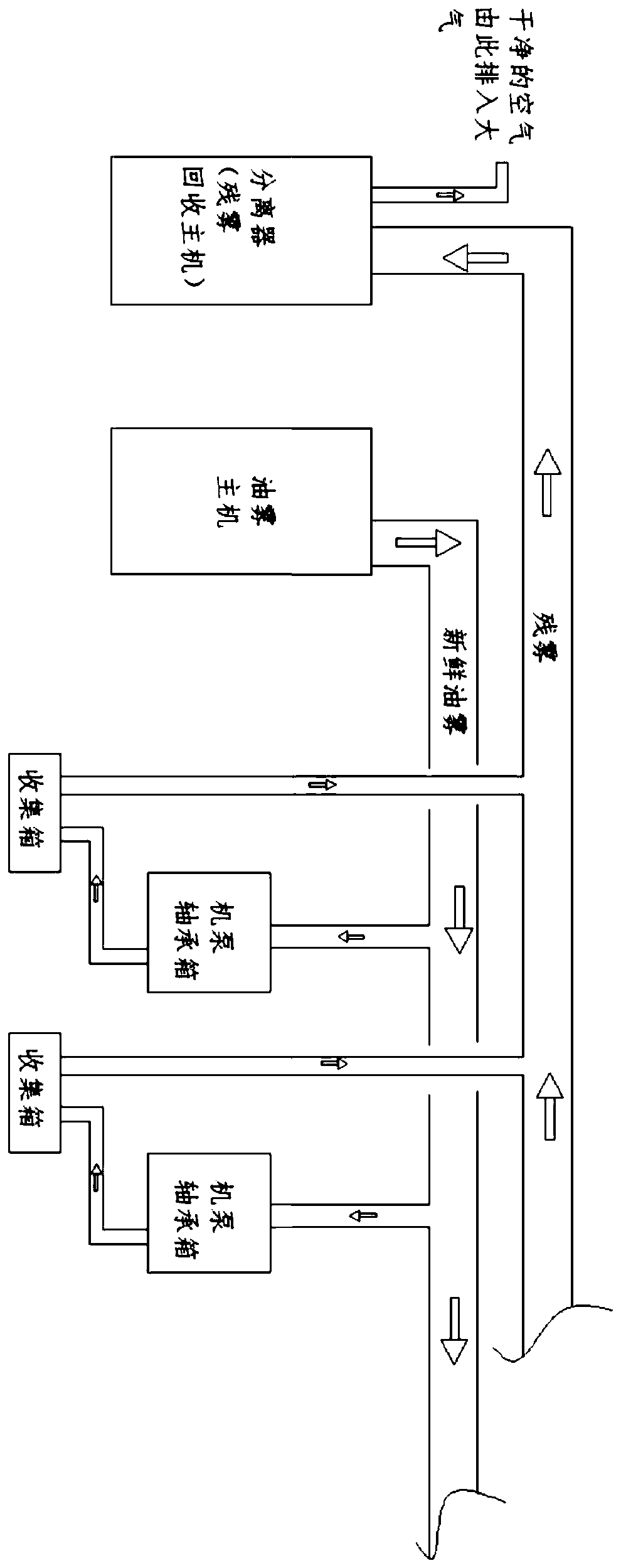

[0022] Such as Figure 1 to Figure 2 As shown, the oil mist lubrication system: the lubricating oil is atomized into oil mist (aerosol mixed with fine oil droplets and instrument wind) by instrument air, and the fresh oil mist is continuously delivered to each machine that needs lubrication through the oil mist delivery pipeline. In the bearing box of the pump, the oil mist passes through the bearing and forms an oil film on the bearing surface to lubricate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com