Method for detecting temperature characteristics of thermoswitch

A thermal switch and temperature characteristic technology, which is applied in the direction of electric switch, measuring device, measuring device, etc., can solve the problems of many touch times of conductive probe detection, high labor intensity of operators, and reduced detection reliability. The effect of feature detection environment is reasonable, detection reliability is improved, and the number of detection touches is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

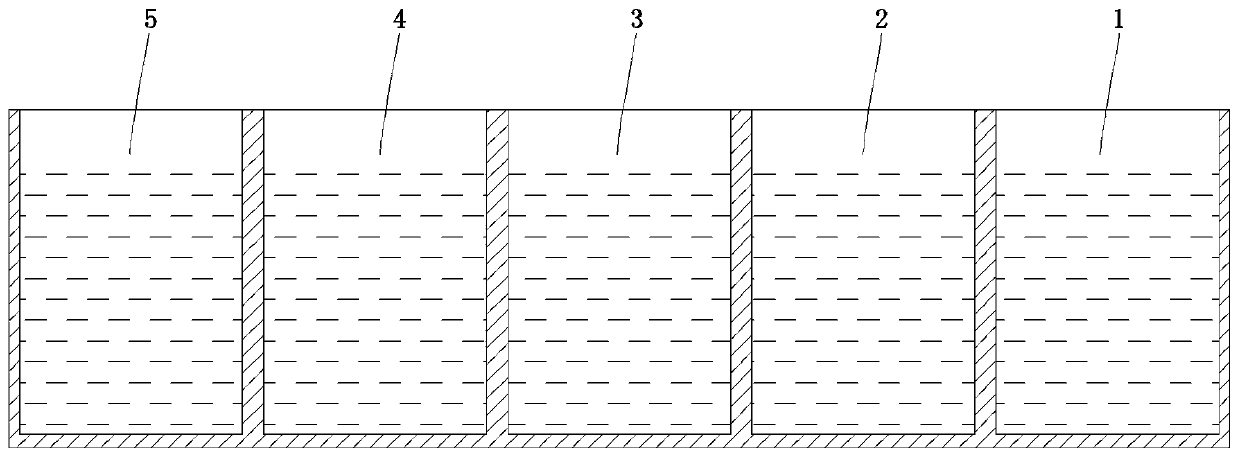

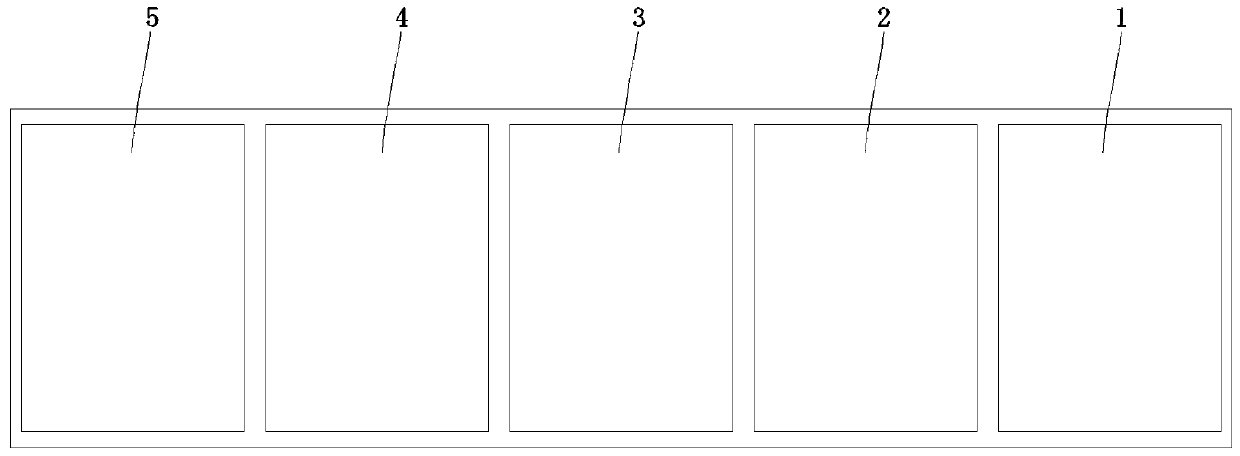

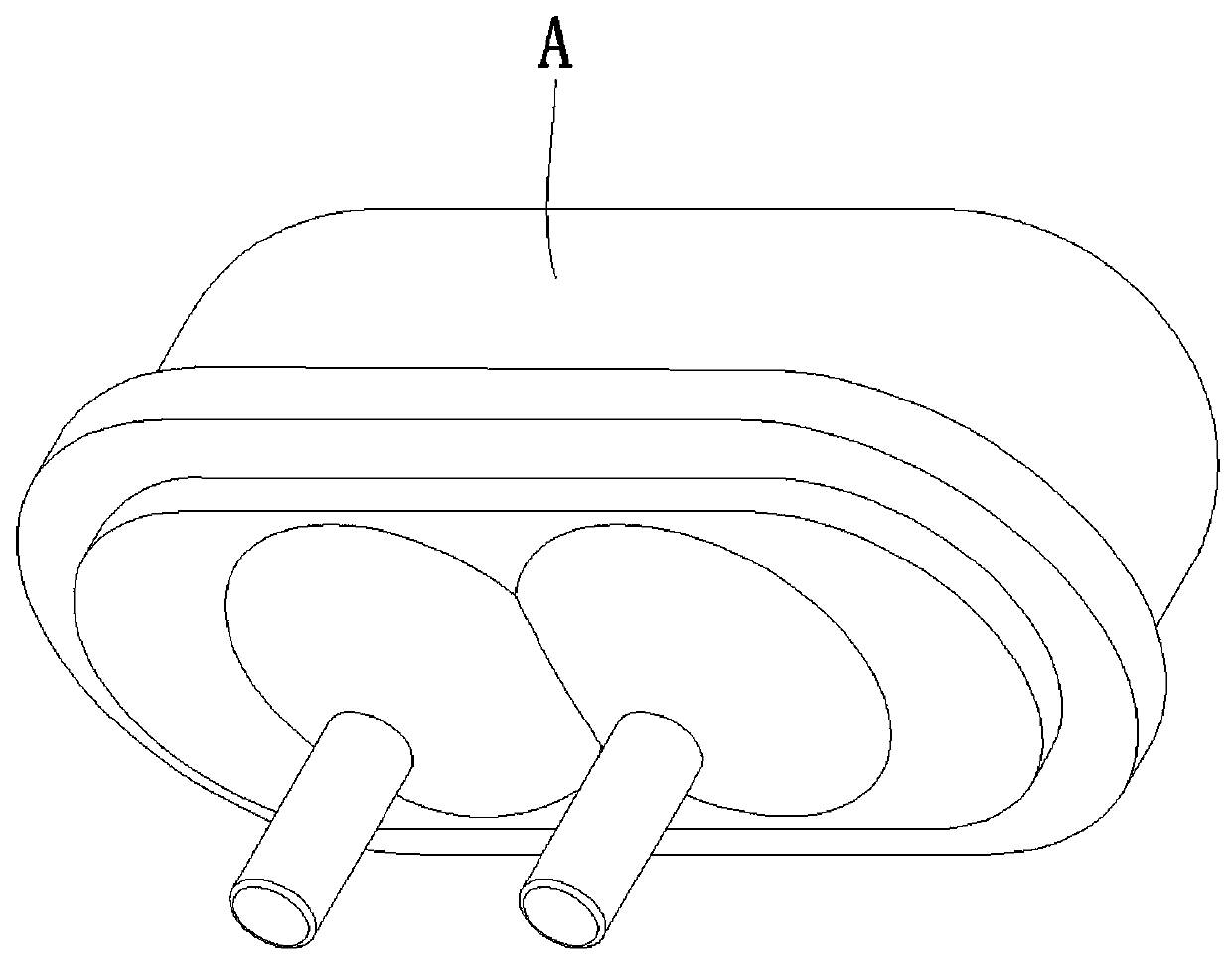

[0022] see Figure 1 to Figure 3 , in order to improve the temperature characteristic detection reliability of thermal switch A, the present invention adopts such a temperature characteristic detection method of thermal switch A, described thermal switch A has several such as 100 to detect simultaneously, specifically comprises the following steps :

[0023] The first step: five oil tanks are set, respectively action lower limit oil tank 1, action upper limit oil tank 2, reset lower limit oil tank 3, reset upper limit oil tank 4 and detection oil tank 5. In the present invention, the oil in the oil tank is preferably silicone oil. The oil temperature in the action lower limit oil tank 1 is equal to the action lower limit temperature of the thermal switch, the oil temperature in the action upper limit oil tank 2 is equal to the action upper limit temperature of the thermal switch, the oil temperature in the reset lower limit oil tank 3 is equal to the temperature of the thermal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap