Simulation and Analysis Method of Fast Wire Harness Principle

A technology of simulation analysis and principles, applied in the field of automotive simulation analysis, can solve problems such as inapplicability of comprehensive inspection of auxiliary design, difficulty in adapting to rapid development and design, missing functions without inspection, etc., to meet the needs of fast completion of design inspection and avoid loss of key information , to avoid the effects of human experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

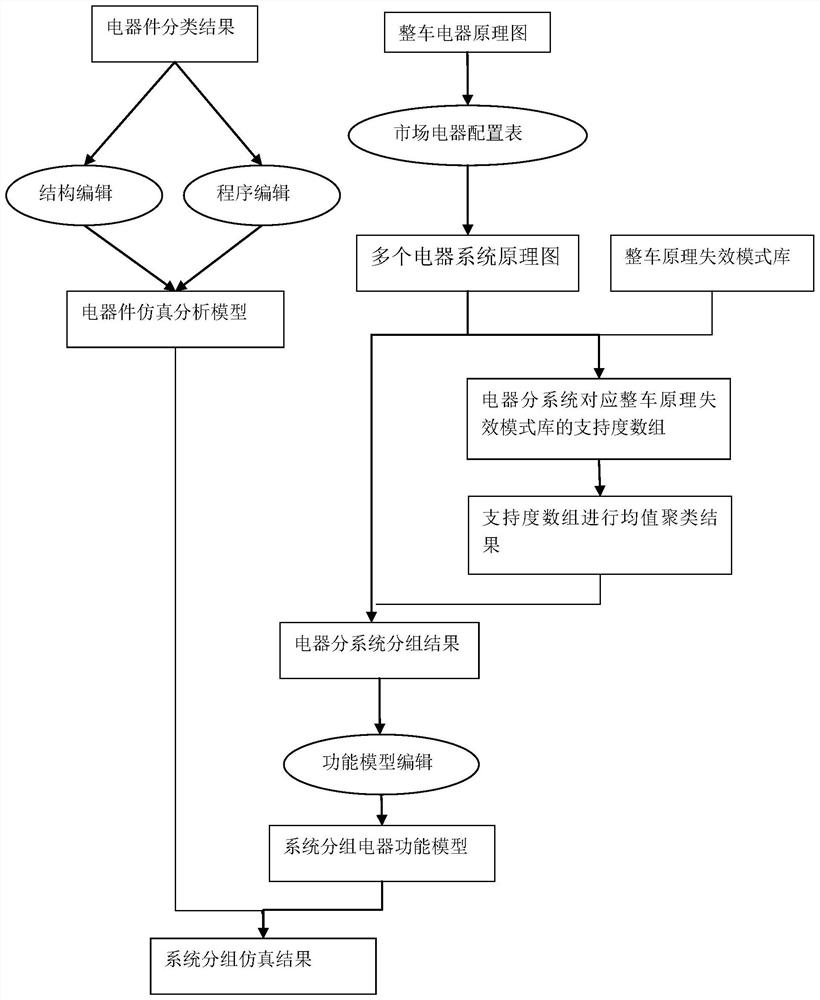

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

[0051] S4: Calculate the support array of the electrical appliance subsystem corresponding to the vehicle principle failure mode library;

[0055] S8: output simulation analysis results.

[0058] S12: the control unit: the electrical components that receive the sensing unit signal and re-issue commands through processing.

[0063] S23: Write a program to the placed electrical pins and each connection according to the electrical function logic.

[0066]

[0072]

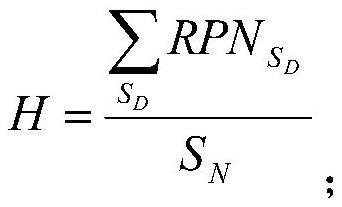

[0073] and calculate the average distance between all samples:

[0074]

[0079]

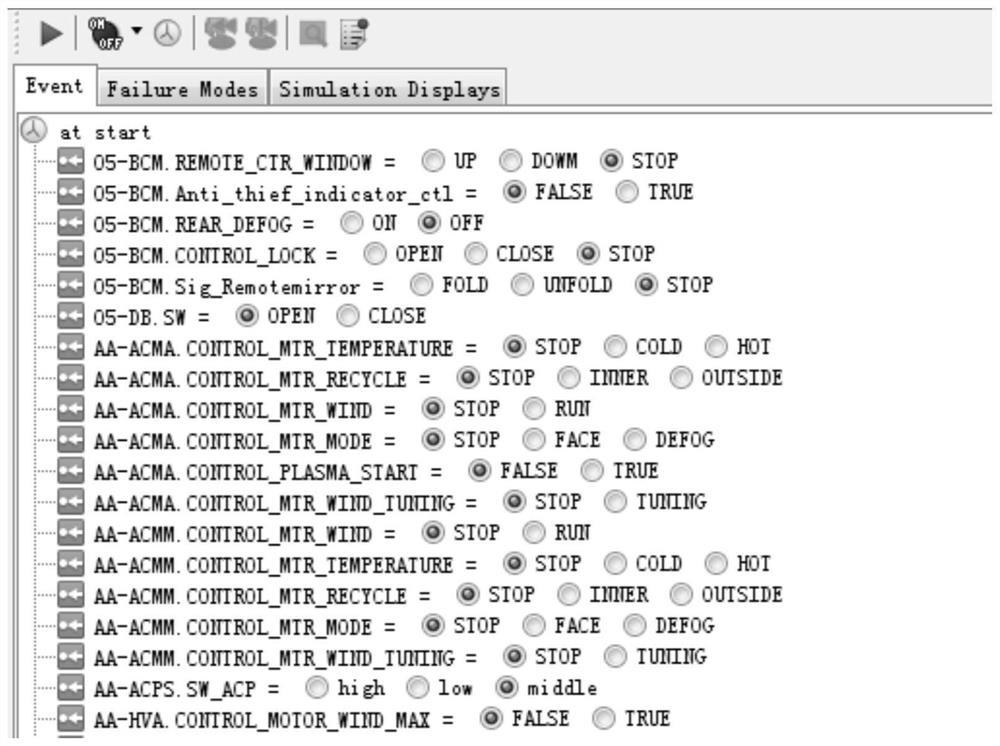

[0082] S62: According to the divided sensing units in step S1, create a human-computer interaction control input factor.

[0085]

[0086] O in the table represents the switch within the simulation range.

[0090]

[0091]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap