Photocurable and heat curable copolymer, photosensitive resin composition, photosensitive resin film and color filter using same

A light-curing and thermal-curing technology, applied in the direction of electric solid devices, semiconductor devices, diodes, etc., can solve the problems of photosensitive resin composition not fully cured, plastic deformation, gas increase, etc., to achieve excellent thermal curability, excellent durability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0162]

Synthetic example 1

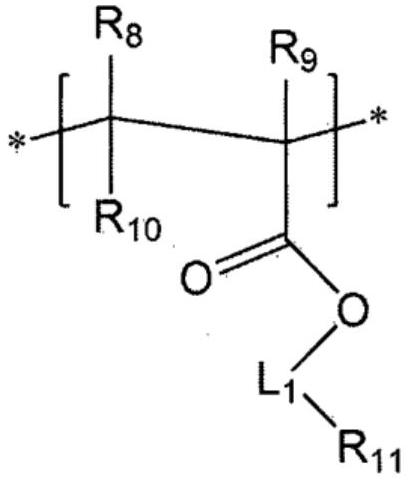

[0164] 5.1% by weight of benzyl methacrylate, 0.8% by weight of N-phenylmaleimide, 0.6% by weight of styrene and 13.2% by weight of glycidyl methacrylate and 78.9% by weight of % propylene glycol methyl ether acetate (PGMEA) solvent to dissolve them, and then the temperature of the solution was raised to 75° C. under nitrogen atmosphere. When the temperature of the reactants reached 75°C, 1.2% by weight of thermal initiator V-65 was added, and then the reactants were allowed to react for 12 hours. To the obtained resin solution, a thermal polymerization inhibitor and a catalyst were added, and then 0.1% by weight of methacrylic acid was introduced under an air atmosphere, and the reactants were reacted for 16 hours while keeping the temperature at 120°C. The weight-average molecular weight of the prepared photocurable and thermally curable copolymer is 4500g / mol, and the content of (meth)acrylate repeating units substituted with epoxy groups at the end of the branched chain is...

Synthetic example 2

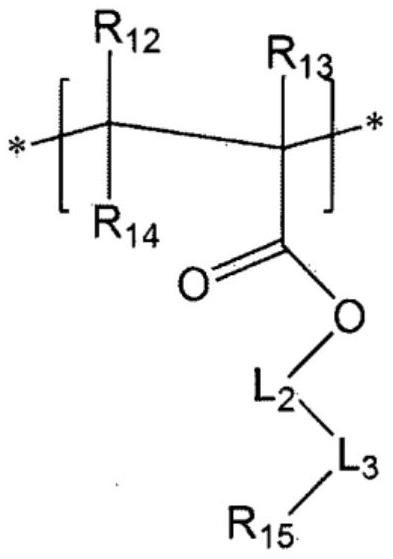

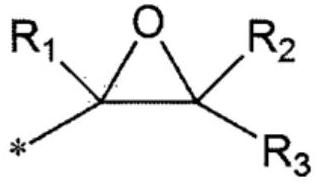

[0166] A photocurable and thermally curable copolymer was synthesized by the same method as in Synthesis Example 1, except that 3,4-epoxycyclohexylmethyl methacrylate was used instead of glycidyl methacrylate. The weight-average molecular weight of the prepared photocurable and thermally curable copolymer is 4700g / mol, and the content of (meth)acrylate repeating units substituted with epoxy groups at the end of the branched chain is 49mol%. The content of the (meth)acrylate repeating unit substituted with an alkenyl group at the terminal was 21 mol%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com