Rectified light component and heavy component liquid-liquid separator and separation method

A liquid separator and light component technology, applied in separation methods, chemical instruments and methods, immiscible liquid separation, etc., can solve problems that weaken market competitiveness, affect production operation and product quality, and save valuable space , Conducive to management and maintenance, low investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

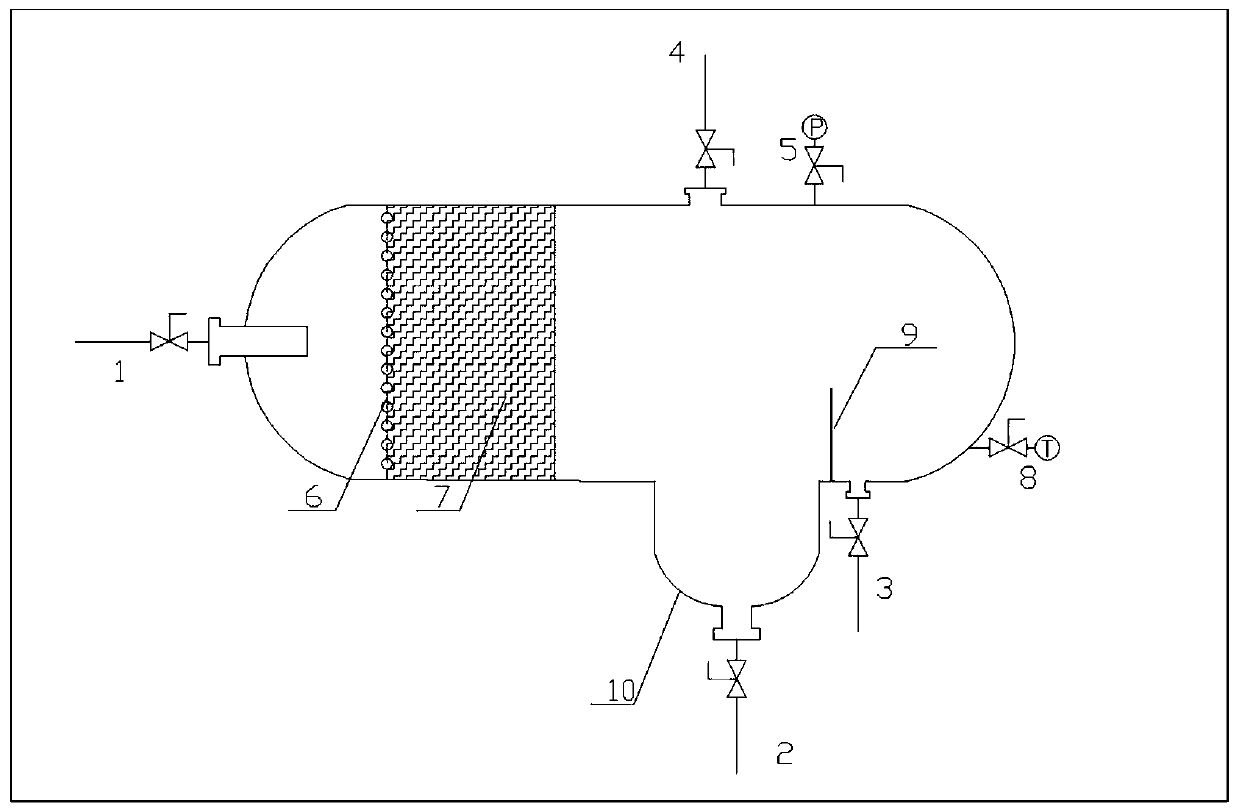

[0019] A kind of acetic acid rectification light component and heavy component liquid-liquid separator, such as figure 1 As shown, the liquid-liquid separator includes a heavy component and light component mixed liquid inlet 1, a liquid distribution plate 6, a wire mesh corrugated packing 7, an exhaust port 4, a water-in-water cylinder 10, a heavy component outlet 2, an overflow Flow baffle 9, light component outlet 3, pressure gauge 5, thermometer 8;

[0020] The liquid distribution plate 6, the wire mesh corrugated packing 7 and the overflow baffle 9 are arranged in the liquid-liquid separator;

[0021] 268 holes are evenly distributed on the liquid distribution plate 6;

[0022] The heavy component and light component mixed liquid inlet 1 of the liquid-liquid separator and the liquid distribution plate 6 are arranged on one side of the wire mesh corrugated packing 7, and the liquid distribution plate 6 is located in the heavy component and light component mixed liquid Bet...

Embodiment 2

[0028] A liquid-liquid separation method of acetic acid rectification light components and heavy components using the liquid-liquid separator described in Example 1, the method is: the material enters the liquid-liquid through the heavy component and light component mixed liquid inlet 1 The separator uses the liquid distribution plate 6 to break the turbulent state of the mixed liquid, making the flow state of the mixed liquid more stable. At this time, the mixed liquid enters the wire mesh corrugated packing 7 for liquid-gas collision separation. The mesh corrugated packing 7 undergoes rebound separation, so that a small amount of gas contained in the liquid gradually moves up and is discharged from the exhaust port 4. At the same time, the light components and heavy components are further separated in the wire mesh corrugated packing 7 to meet the separation requirements. The component enters the water-in-water cylinder 10 and returns to the system from the heavy component ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com