Drying device for rubber and plastic product production

A drying device and technology for rubber and plastic products, applied in the field of rubber and plastic products, can solve the problems of reducing drying efficiency, wasting cooling liquid, wasting time and effort, etc., and achieve the effects of improving drying efficiency, avoiding waste, and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

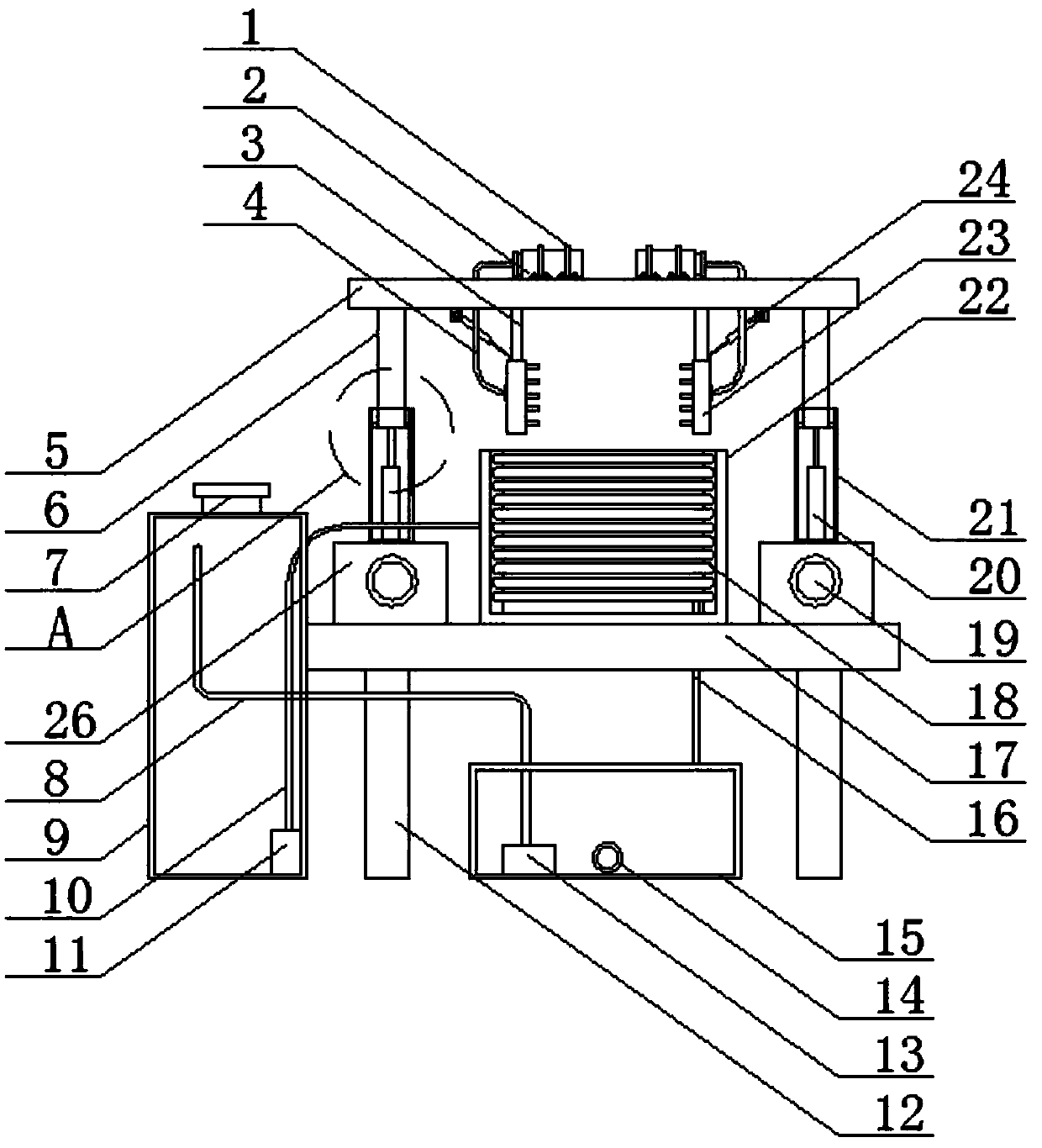

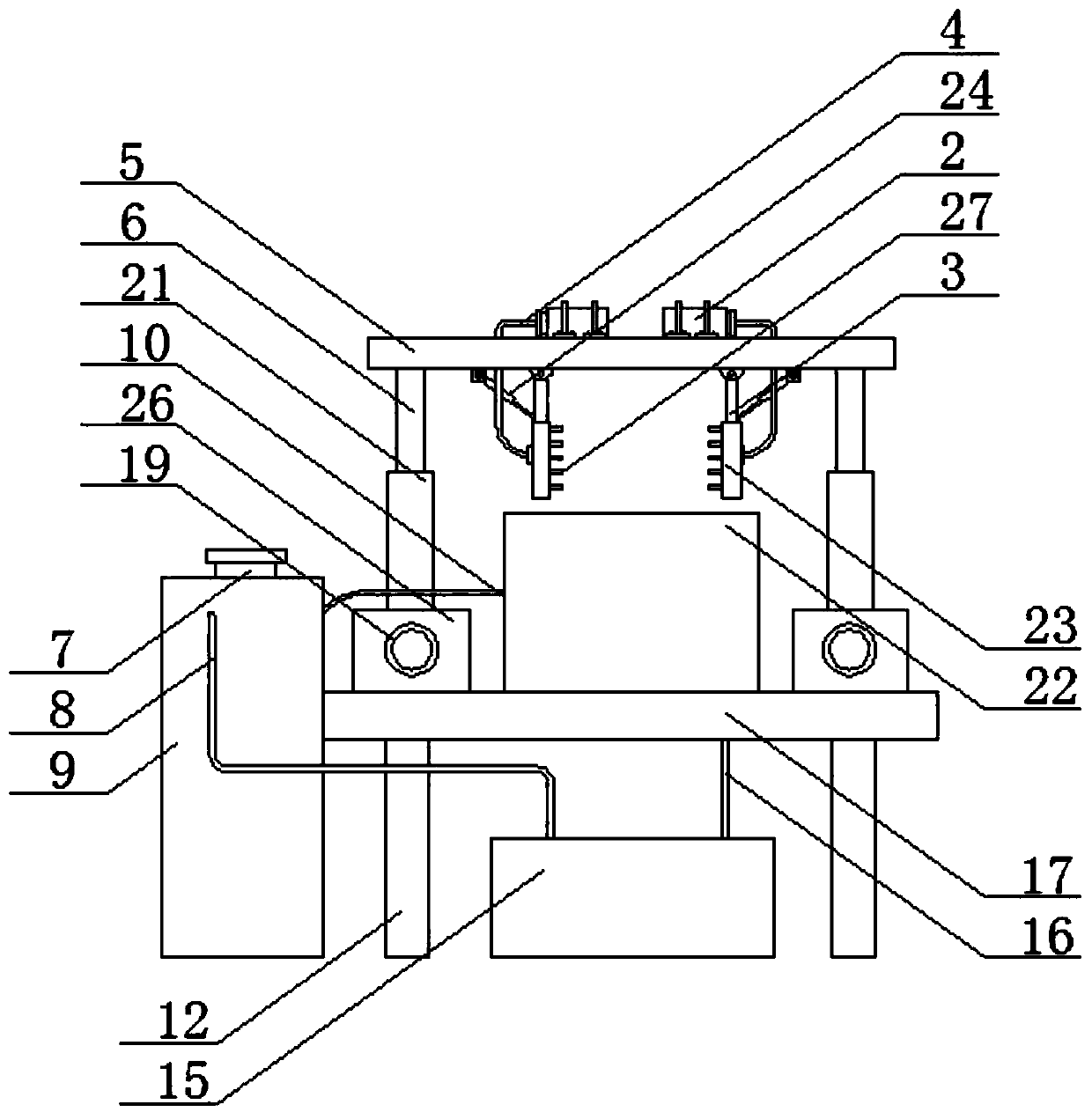

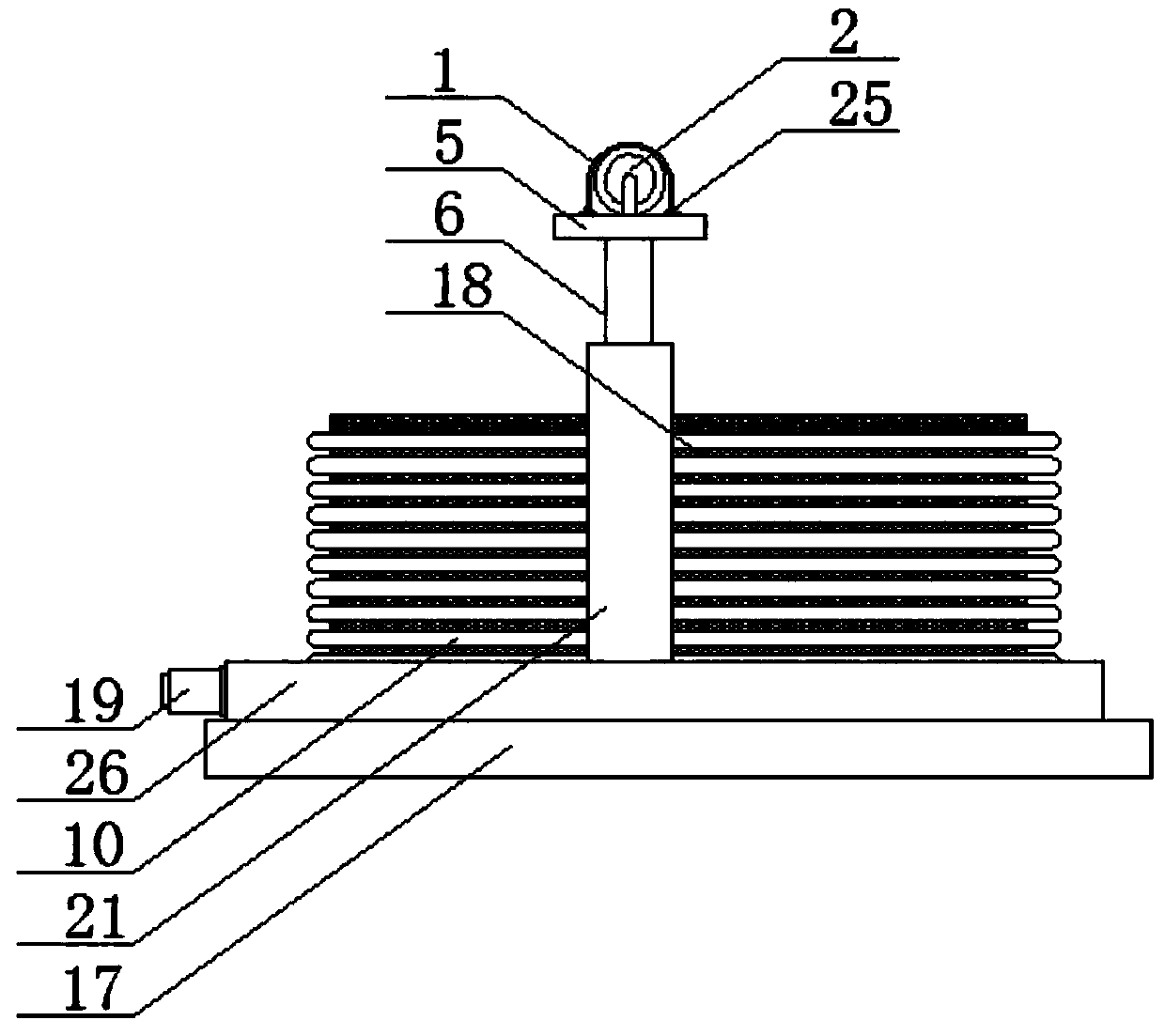

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0029] refer to Figure 1-6 , a drying device for the production of rubber and plastic products, comprising four bearing rods 12 for convenient support and fixing, the upper ends of the four bearing rods 12 are jointly fixed with a bearing block 17, and the upper end of the bearing block 17 is fixed with a placement box 22, and the placement box The bottom inside 22 is placed with filter box 18, is wound with the first water pipe 10 on the side wall of filter box 18, is convenient to the outside of filter box 18 is cooled, and one side of bearing block 17 is provided with first water tank 9, the first The bottom in the water tank 9 is fixed with the first water pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com