Flexible lifting appliance

A spreader and hoisting technology, applied in the direction of load hoisting components, transportation and packaging, can solve the problems such as the difficulty of clamping and transporting the opening parts, and achieve the effects of improving quality and safety risks, wide application and simple use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

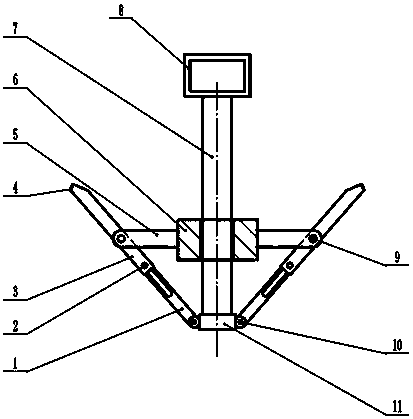

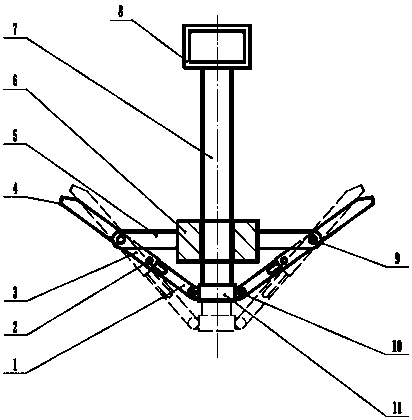

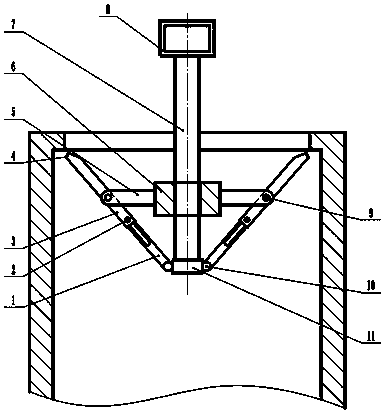

[0019] figure 1 Among them, the present invention consists of a telescopic rod, a support rod 5, a sliding sleeve 6, a hoisting main rod 7 and a hoisting ring 9. The telescopic rod is composed of a telescopic rod proximal component 1, a telescopic rod pin 2, a telescopic rod distal component 3, and a telescopic rod. The end assembly 4 is composed.

[0020] The hoisting ring 8 is hung on the crane hook, the hoisting main pole 7 is fixedly connected to the hoisting main pole, and the hoisting main pole end stop assembly 11 is fixed to the issuing end of the hoisting main pole 7.

[0021] The sliding sleeve 6 is sleeved on the hoisting main pole 7, and can slide freely on the hoisting main pole 7. The sliding sleeve 6 is fixed with 3 or more support poles 5, and the sliding sleeve 6 drives the supporting pole 5 along the hoisting main pole 7 Swipe up and down.

[0022] The outermost end of each support rod 5 and the hole on the middle side of the telescopic rod distal assembly 3 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com