Steerable prefabricated FRP anti-collision guardrail or prestress concrete bridge

An anti-collision guardrail and concrete technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as excessive concrete weight, and achieve the effects of reducing collision damage, speeding up construction progress, and convenient and fast installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

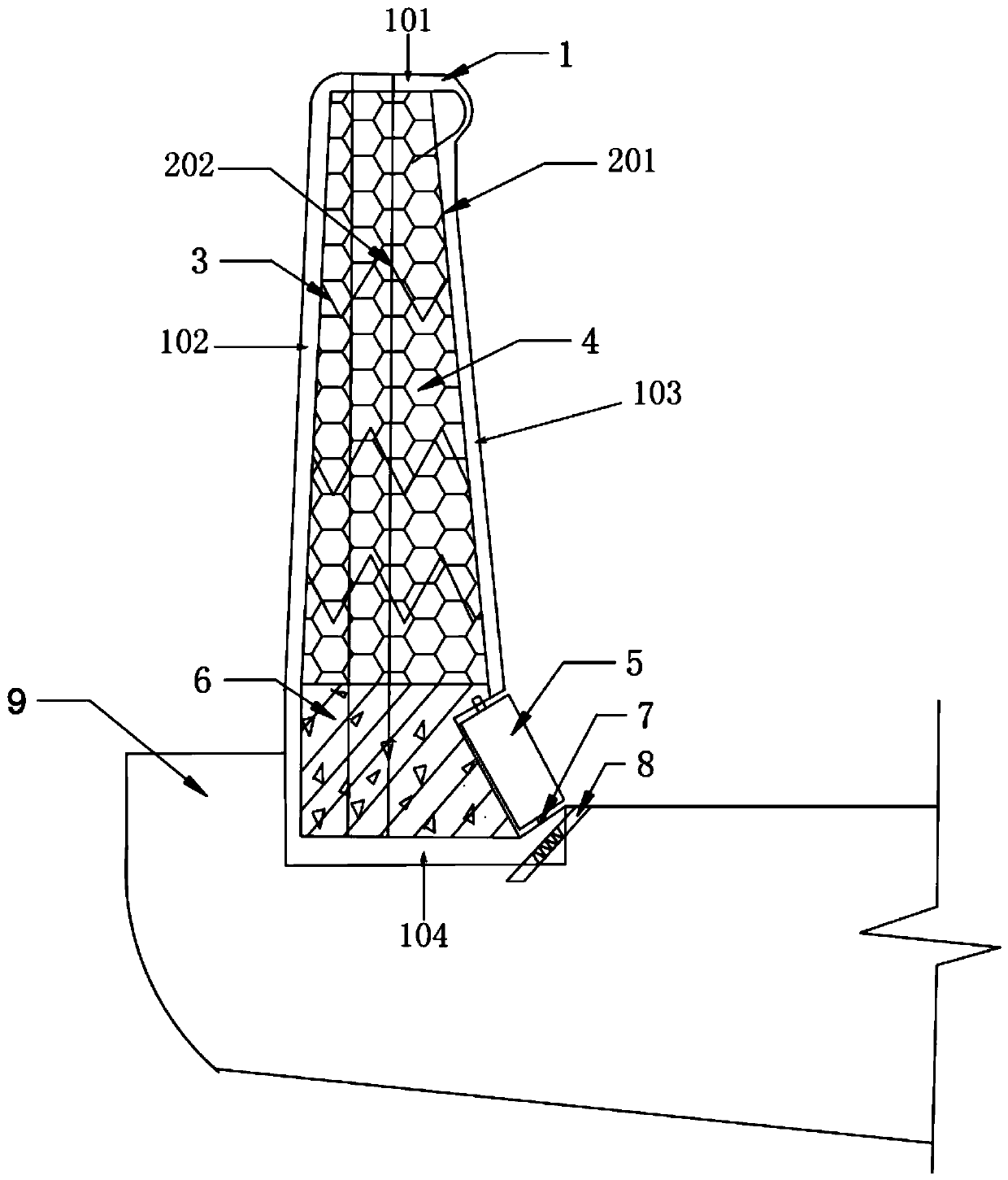

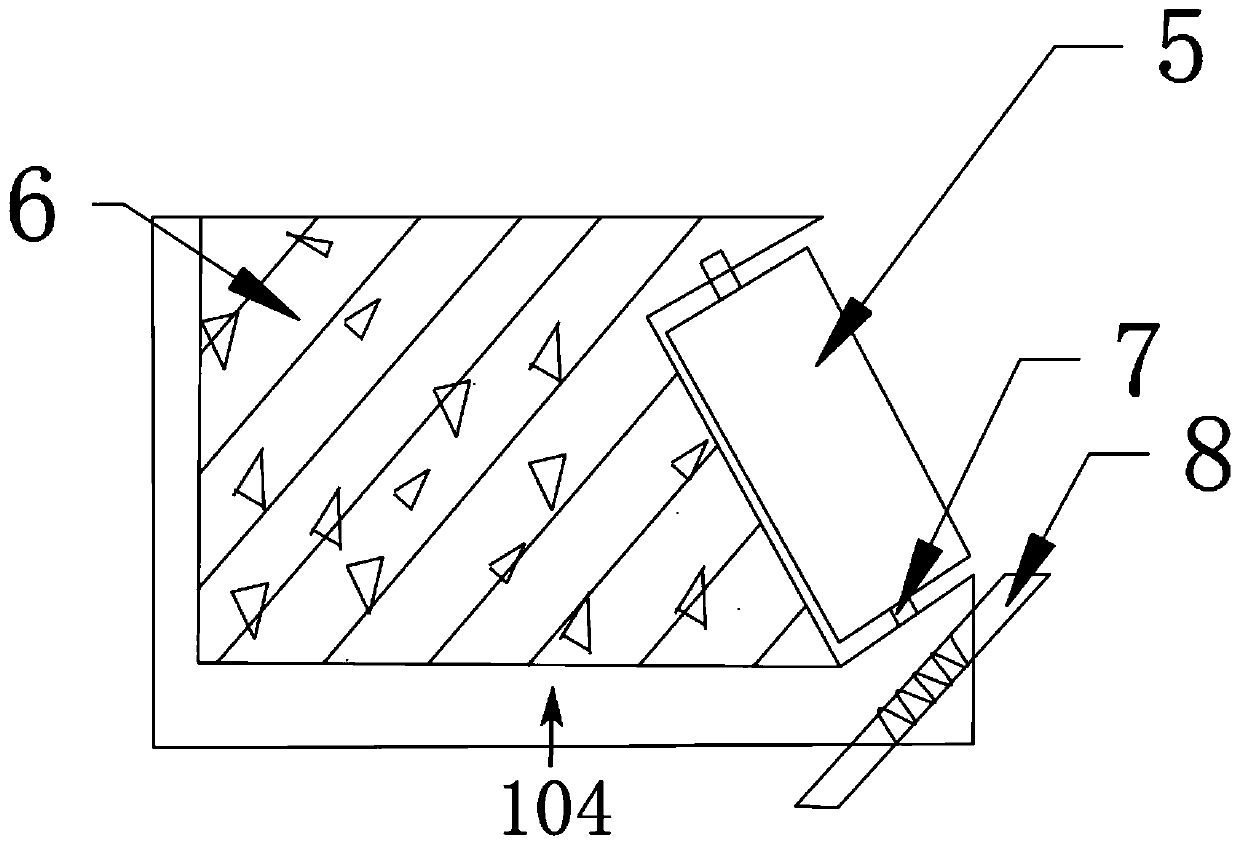

[0029] Embodiment one: see Figure 1-Figure 5 .

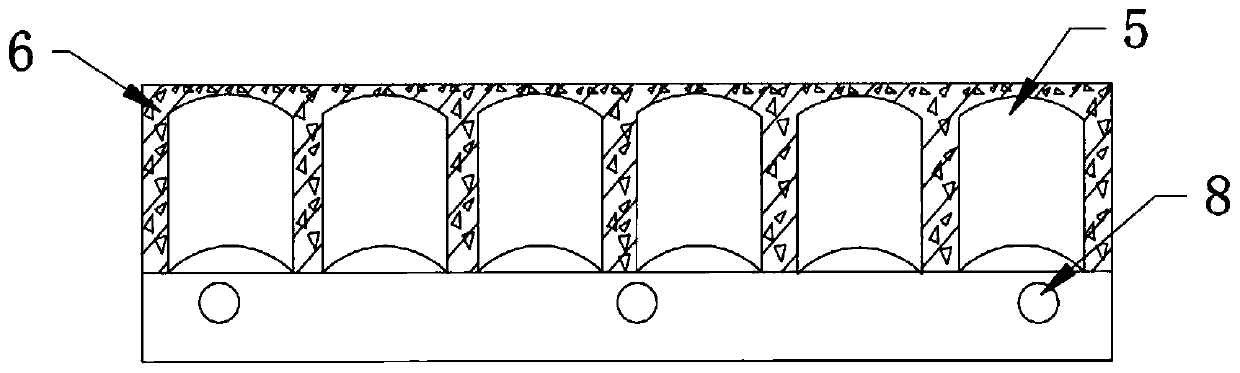

[0030] The invention discloses a steerable prefabricated FRP anti-collision barrier applied to prestressed concrete bridges, which comprises a prefabricated FRP anti-collision shell component 1, and the prefabricated FRP anti-collision shell component 1 is composed of an upper shell 101, an outer shell 102, an inner shell The shell 103 and the bottom shell 104 form a hollow shell, the bottom of the prefabricated FRP anti-collision shell component 1 is filled with a concrete base 6, and the prefabricated FRP anti-collision shell component 1 is firmly connected with the bridge. The outer side is provided with a reserved position for installing the steering drum 5, and the steering drum 5 is connected to the reserved position of the base through the axle 7; inside the prefabricated FRP anti-collision shell member 1, there are structural steel bars 201, vertical steel bars 202, W Shaped low yield point steel plate 3, the structura...

Embodiment 2

[0044] Embodiment two: see Figure 6-9 .

[0045] The similarities between this embodiment and the embodiment will not be described in detail, the difference is that in this embodiment, the stopper 9 is cancelled.

[0046] When canceling stop 9:

[0047]S1. During the construction of the bridge deck, the base of the guardrail and the bridge deck are integrally poured, the structural steel bars 201 and the vertical steel bars 202 are arranged, and the axle 7 and the roller 5 are assembled.

[0048] S2. Connect the low-yield point steel plate 3 to the structural steel bar 201, insert the low-yield point steel plate 3 between the vertical structural steel bars 202, assemble the upper shell 101 and the outer shell 102, and fix them to the structural steel bar 201.

[0049] S3. Fill the buffer material and assemble the inner shell 103 .

[0050] When the guardrail is hit, 103 is the force bearing surface. If the car wheel or the body hits the drum 5 somewhere, the drum rotates, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com