Construction device and construction method for tube pile in dense sand stratum

A technology for construction equipment and pipe piles, which is applied in sheet pile walls, infrastructure engineering, construction, etc., and can solve the problems of easy bending and inclination of drilling holes, difficult pile driving, and easy to collapse holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

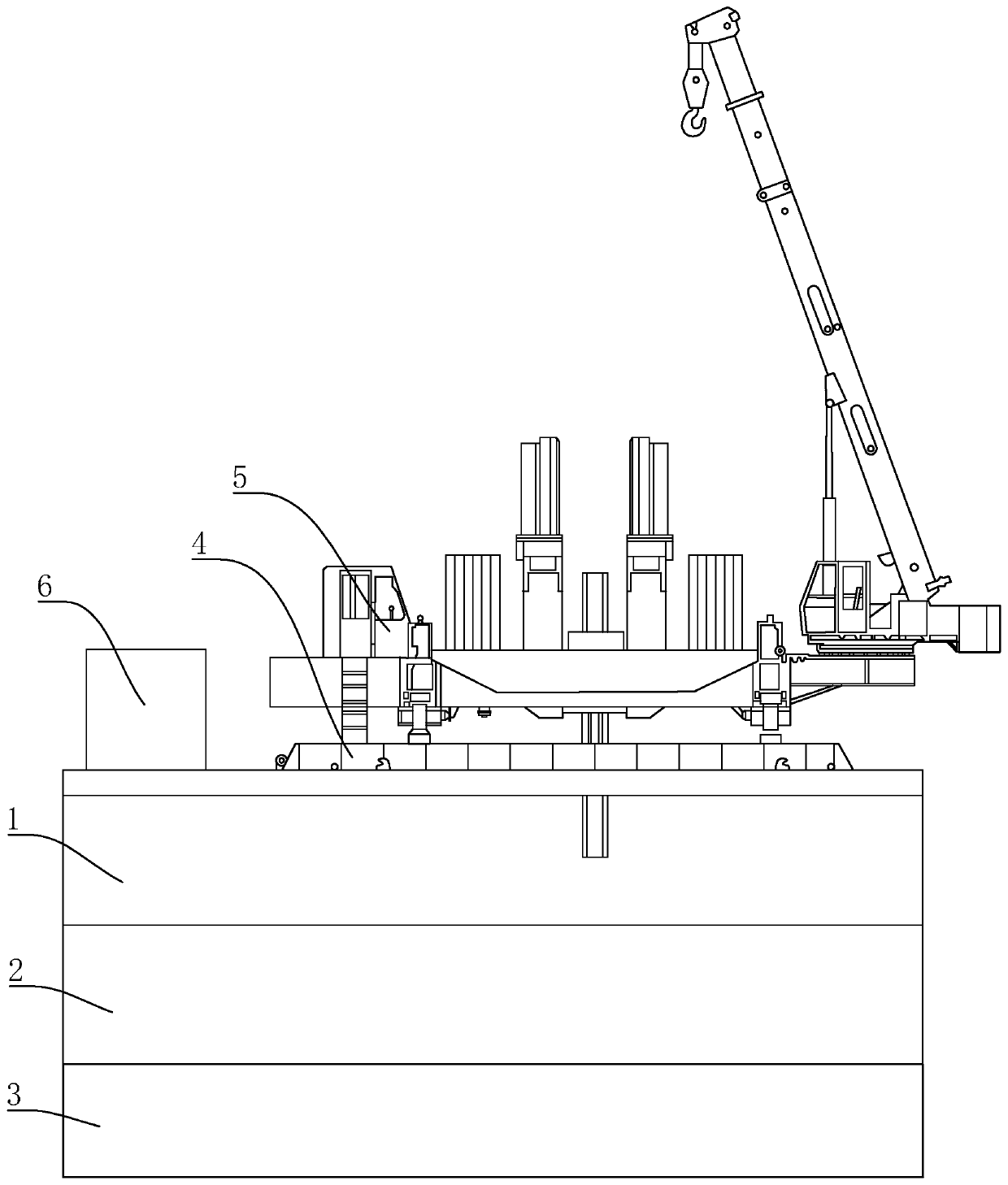

[0036] Embodiment: a kind of construction equipment of pipe pile in dense sand layer, such as figure 1 As shown, including the first clay layer 1, the sandy soil layer 2, and the second clay layer 3, a construction platform 4 is arranged above the first clay layer, and a static pile driver 5 is arranged at the upper end of the construction platform 4, and the static pile driver 5 and the The pipe piles are linked together. When sinking the piles, the pipe piles are linked with the static pile machine 5, and the static pile machine 5 is started, so that the static pressure pile machine 5 drives the pipe piles to sink, and the pipe piles can be sunk smoothly. In the first clay layer 1.

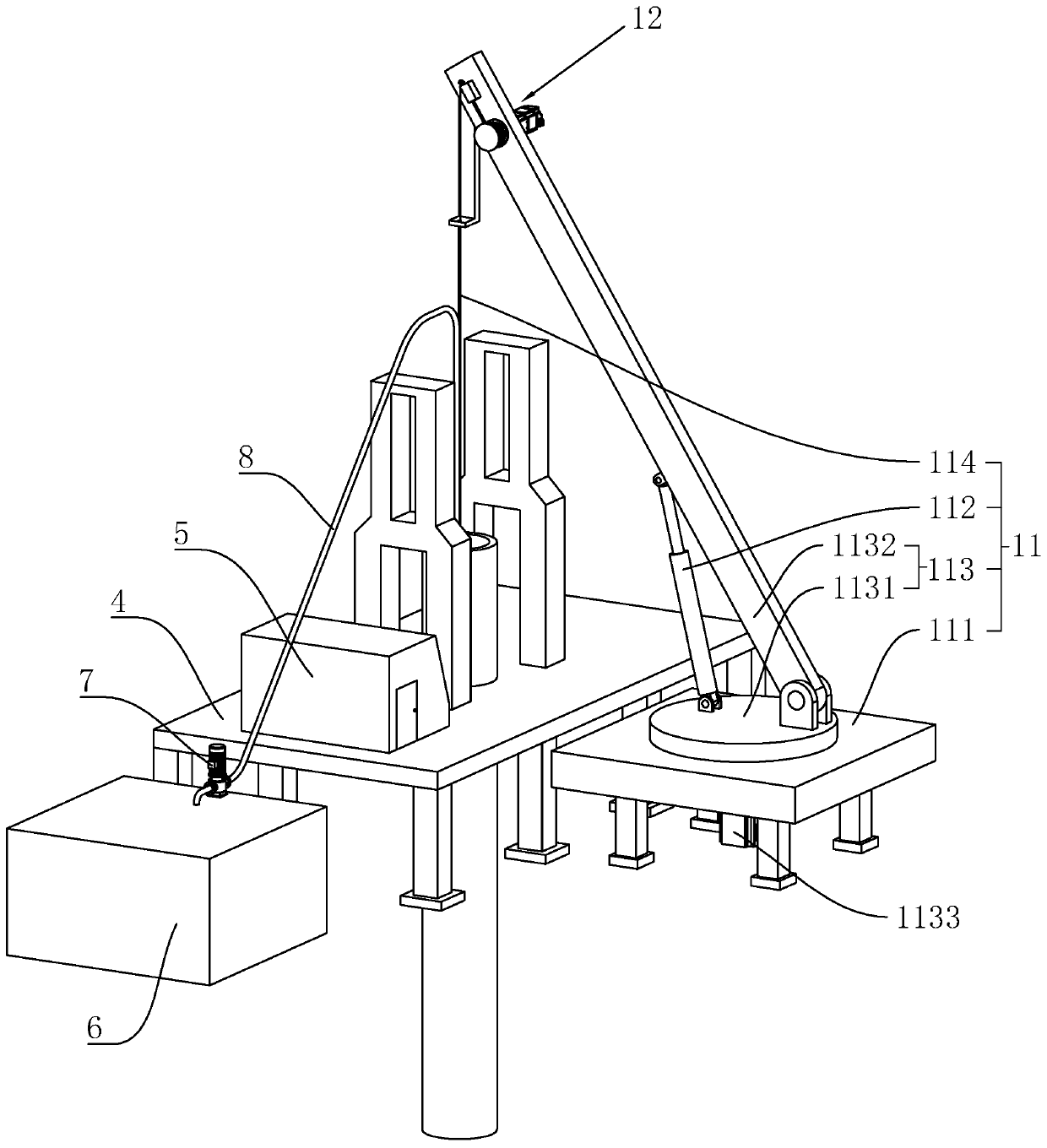

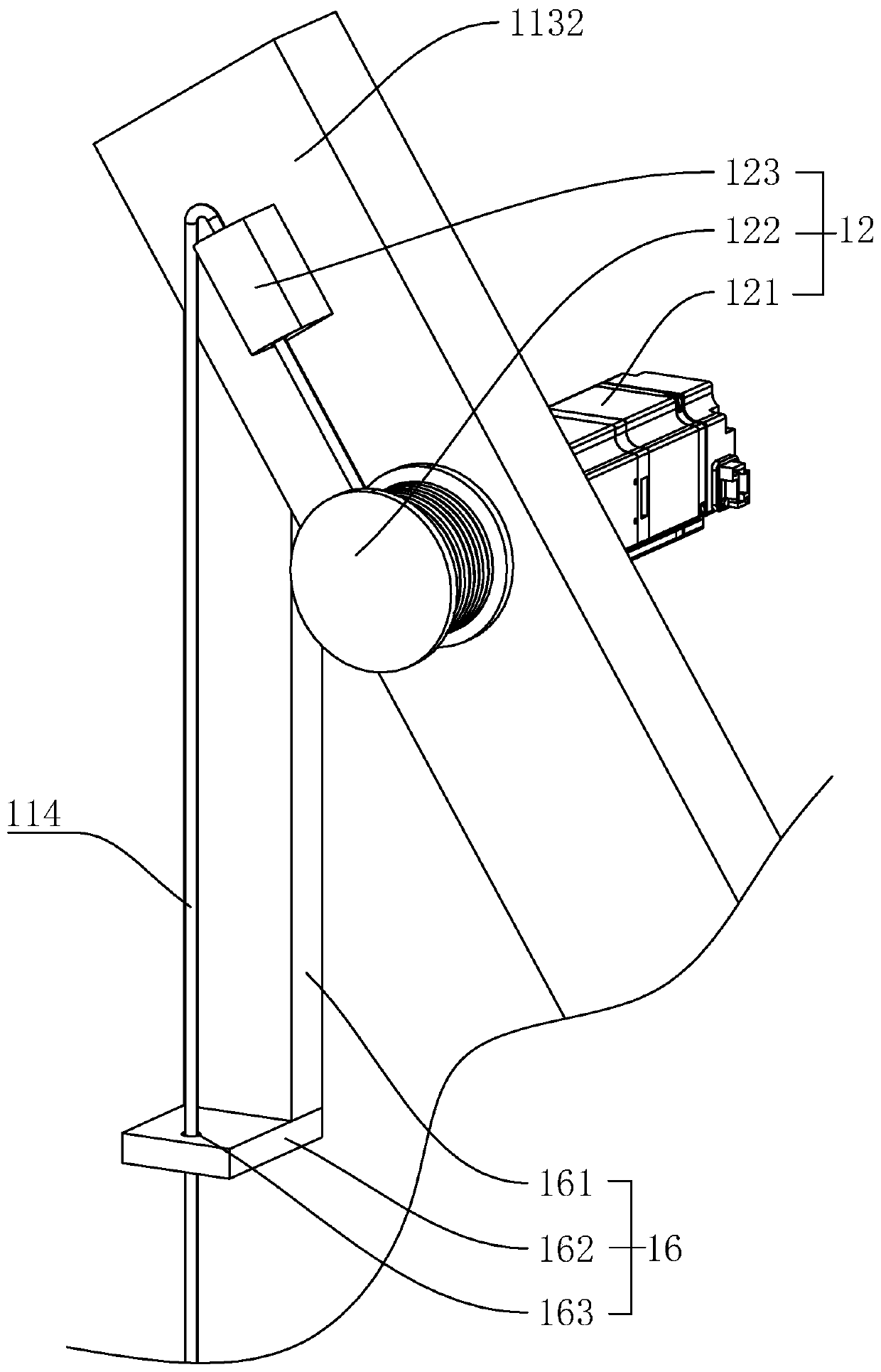

[0037] Such as figure 2 As shown, one side of the construction platform 4 is provided with a water tank 6 and a support mechanism 11, the upper end of the water tank 6 is fixedly connected with a water pump 7, and the water pump 7 is linked with a water delivery pipe 8, one end of the water de...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap