Construction method for rotary jet prefabricating of composite pile

A construction method and technology of composite piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems that pile foundations cannot be constructed and large-scale pile foundation construction machinery cannot enter the construction site, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

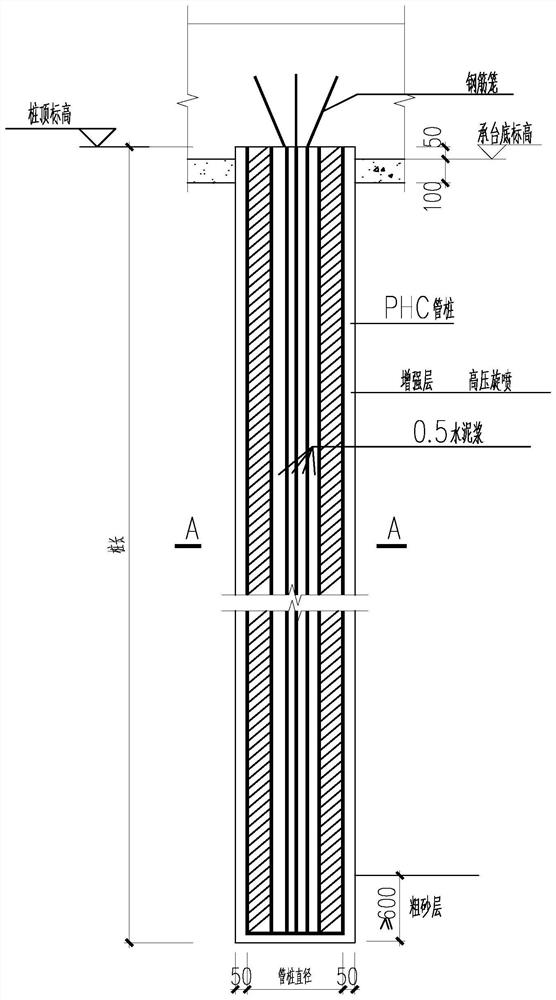

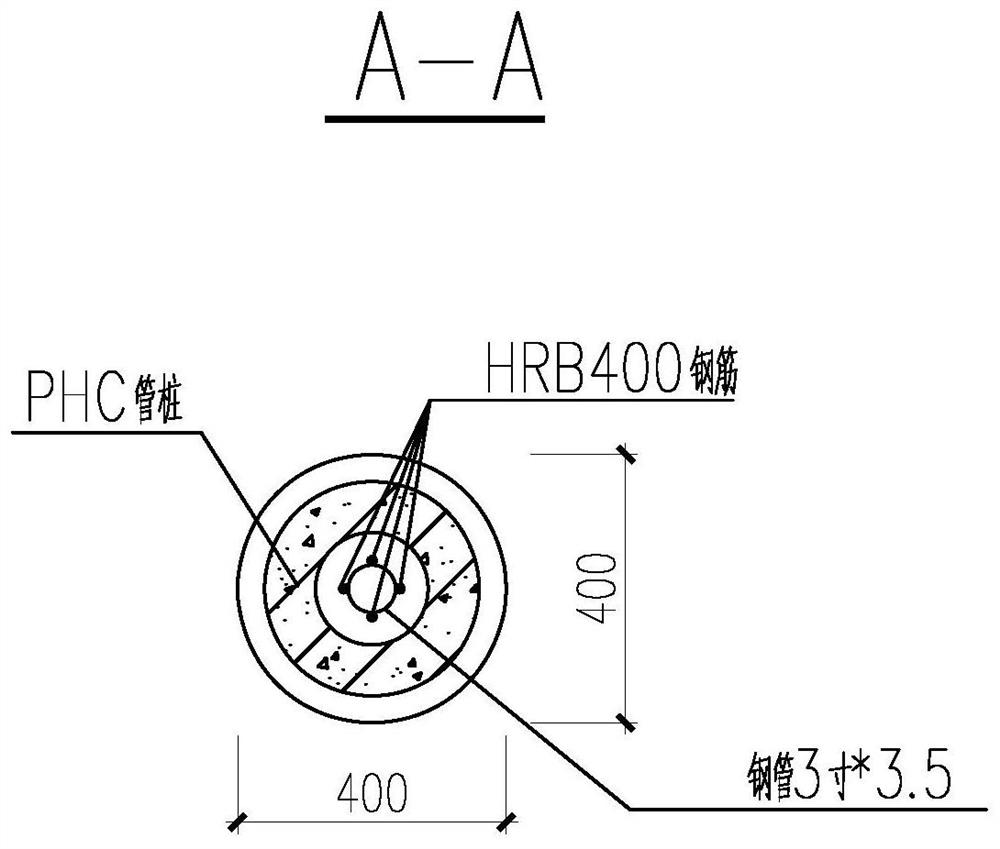

[0029] Specific implementation mode one: as figure 1 with figure 2 As shown, the construction method of the rotary spray prefabricated composite pile of the present embodiment is realized according to the following steps:

[0030] Step 1. Use rotary jet drilling rig for rotary jet drilling:

[0031] Use rotary jet drilling rigs to carry out pile drilling construction in a narrow space;

[0032] Step two, rotary jet grouting:

[0033] During the drilling process, the rotary jet drilling rig sprays the cement slurry through the bottom of the rotary jet drilling rig bit to ensure that the cement slurry is fully stirred after filtering, and the working pressure range of the spraying grout when the rotary jet drilling rig drills in is 7 ~ 10mpa; to ensure that the rotary jet drilling rig The jet grouting pressure is 25-28Mpa when the drill bit is lifted; part of the fine sand in the cement slurry is discharged out of the pile hole along with the cement slurry, and the gap withi...

specific Embodiment approach 2

[0038] Specific embodiment 2: In step 1 of this embodiment, the grouting pressure of the grouting grout is controlled to be 2-4 mpa.

[0039] In this way, the cement slurry has the function of penetration and cementation, and the pressure injection of the cement slurry can increase the resistance of the side of the pile and the resistance of the pile end. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: The water-cement ratio of the cement slurry in Step 1 of this embodiment ranges from 0.5 to 0.8.

[0041] In this way, the strength of the cement slurry is guaranteed, the side resistance of the pile is improved, and the virtual soil at the bottom of the pile is solidified. Other components and connections are the same as those in the second embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap