An on-line heating device for surface rolling of workpieces

A workpiece surface, workpiece technology, applied in the field of online heating devices, can solve the problems of complex equipment, uneven heating, unsafe, etc., to achieve the effect of safe operation and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

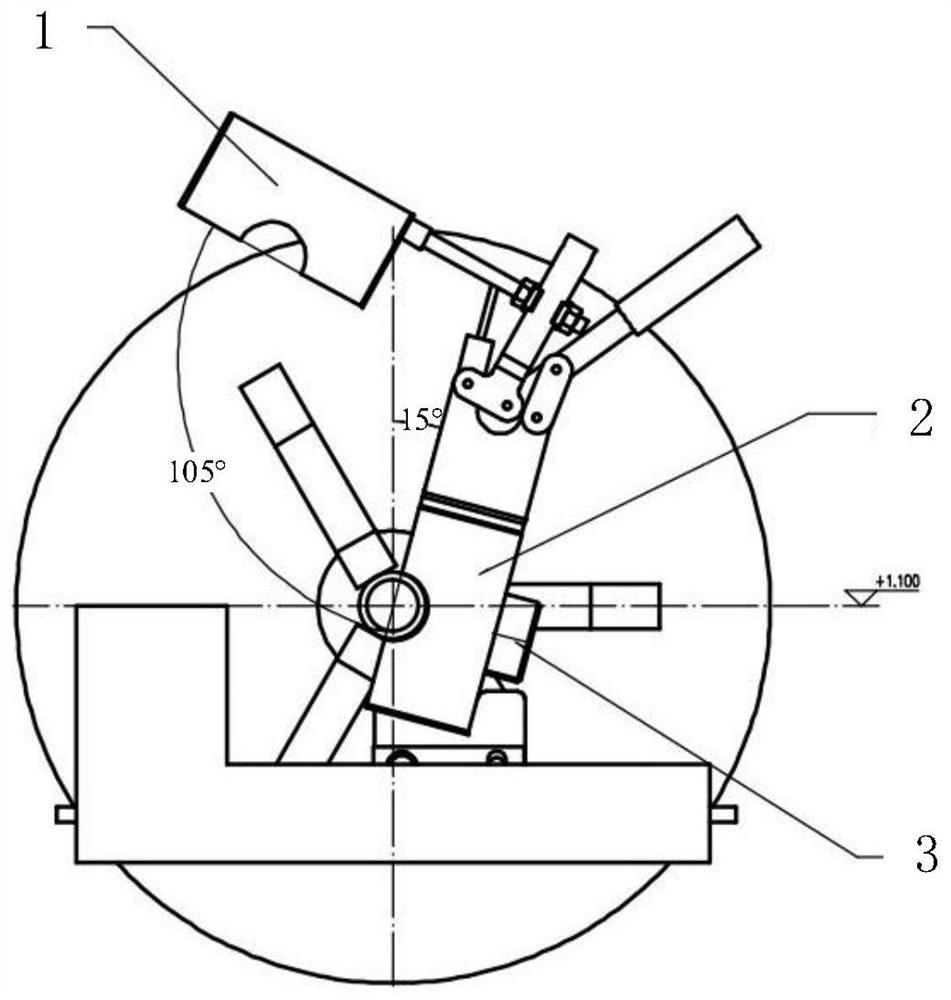

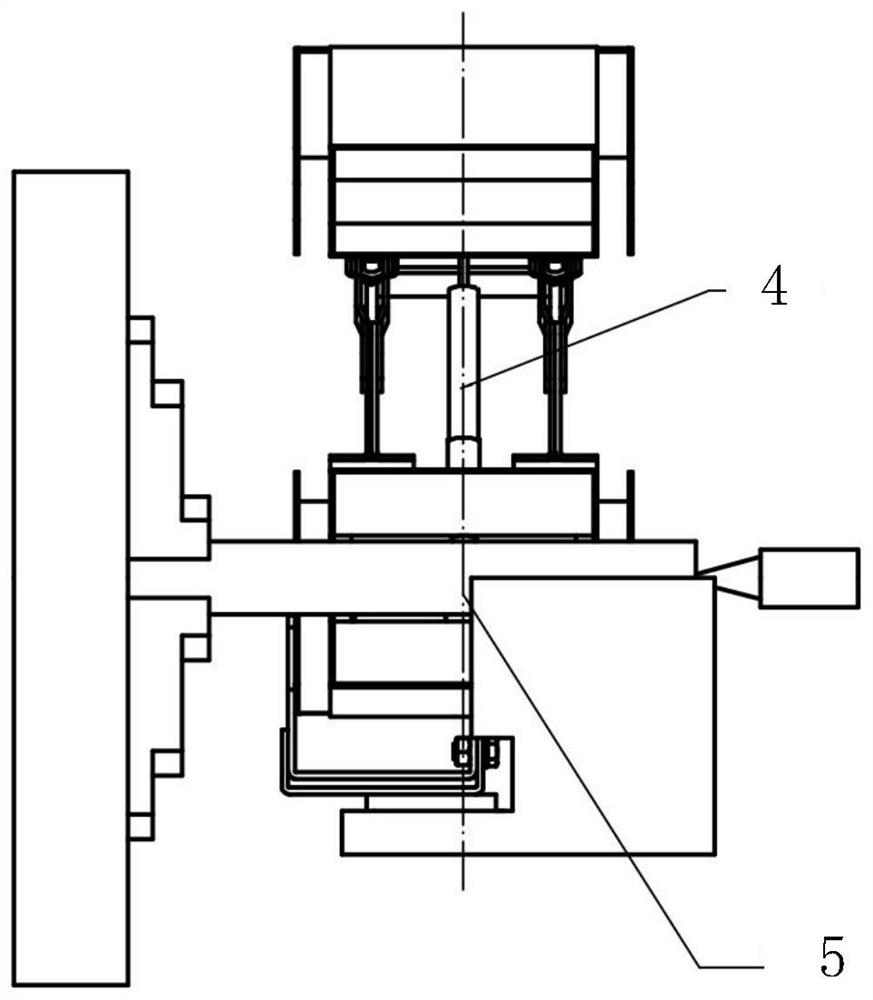

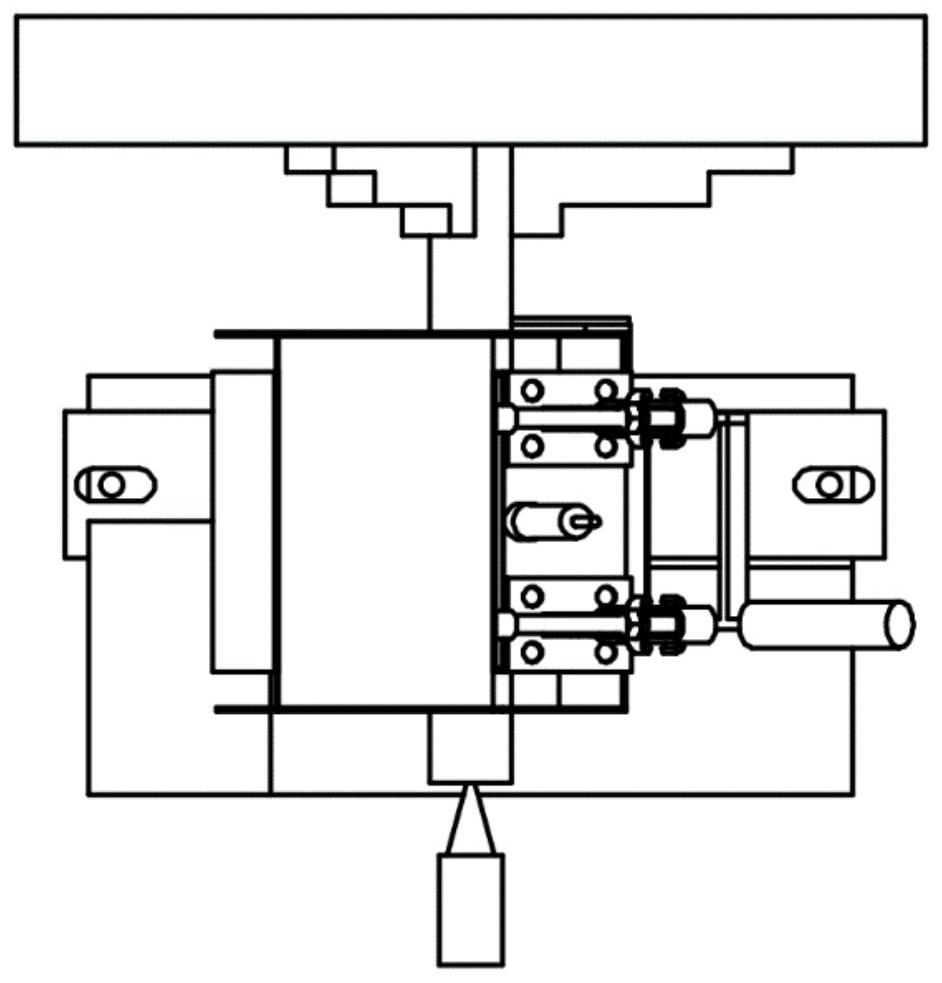

[0022] Such as Figure 1-5 As shown, the surface rolling online heating device is composed of a combustion heater and a gas flow control system. The combustion heater includes a heater moving end 1, a heater fixed end 2, a flame combustion chamber 3, an ignition and temperature measuring device 4; the gas flow The control system includes gas tank 10, screw valve one 11, screw valve two 12, air pressure gauge one 13, pressure reducing valve 14, air pressure gauge two 15, safety valve one 16, screw valve three 17, solenoid valve 18, blower 19. Pressure gauge three 20, safety valve two 21, screw valve four 22, Venturi mixer 23. After the heating command is turned on, the moving end 1 of the heater and the fixed end 2 of the heater are in a closed state, and the gas flows out from the gas tank 10, and then passes through the first screw valve 11, the second screw valve 12, the first air pressure gauge 13, and the pressure reducing valve 14 , air pressure gauge two 15, safety valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com