A metal nut embedding machine for plastic products

A technology for plastic products and nuts, applied in the field of nut assembly equipment and metal nut implanters, can solve the problems of incompetent assembly equipment, difficult quality assurance, single embedding direction, etc., and achieve the effects of low cost, convenient operation and easy replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

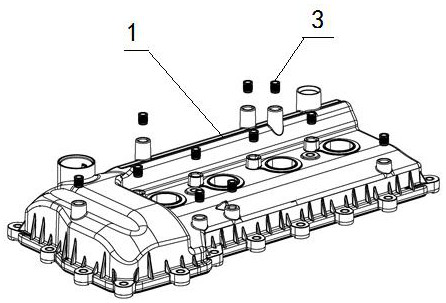

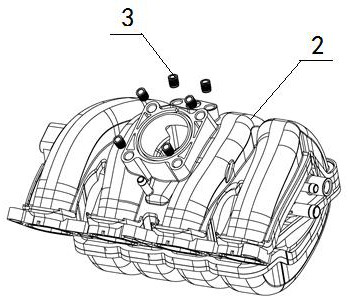

[0034] Such as figure 1 , 2 As shown, a metal nut embedding machine for plastic products is applied to, for example, an engine cylinder cover 1 and an engine intake manifold 2 as shown in the figure, and nuts 3 need to be embedded in these plastic products.

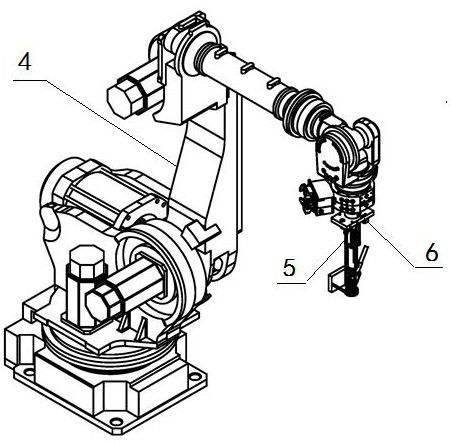

[0035] Such as image 3 As shown, the planting machine includes a mechanical arm 4, a manipulator, and a nut feeding device.

[0036] Such as Figure 4 , 5 , 6 and 7, the manipulator includes a nut pushing cylinder 5 connected to the manipulator, the cylinder is connected to the manipulator, and a pressure sensor 6 is set between the cylinder and the manipulator to detect the pressure of the manipulator.

[0037] The nut pushing cylinder is connected to the sleeve 7, and the pushing rod 8 is arranged in the sleeve, and the pushing rod is connected with the piston of the nut pushing cylinder, and the end of the sleeve is connected with the nut guiding cavity, and the nut guiding cavity is provided with a nut passage 9....

Embodiment 2

[0046] Such as Figure 13 , 14 As shown, different from the above-mentioned embodiments, the internally supported collet is a two-way shape memory alloy, and when the temperature is higher than the high-temperature phase transition temperature of the shape memory alloy, the internally supported collet expands (i.e. The cross notch of the head is divided into four parts slightly outward), so as to clamp the nut. When the temperature is lower than the high-temperature phase transition temperature of the shape memory alloy, the inner support collet shrinks, so that the nut is lifted from the inner support collet To disengage, the nut is provided with an electric heating component corresponding to the discharge port of the nut guide chamber, such as a resistance heating wire, so as to realize the heating of the nut.

[0047] Tension return springs are connected between the upper ends of the two movable cavity walls and the cavity, and magnets 21 that attract each other are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com