Driving type expansion joint and application thereof

A telescopic joint and drive-type technology, applied in the direction of adjustable connections, pipes/pipe joints/fittings, passing components, etc., can solve problems such as labor-intensive, large air leakage rate, inconvenient operation, etc., to prevent collision accidents and equipment damage, Improve duct ventilation and reduce air leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

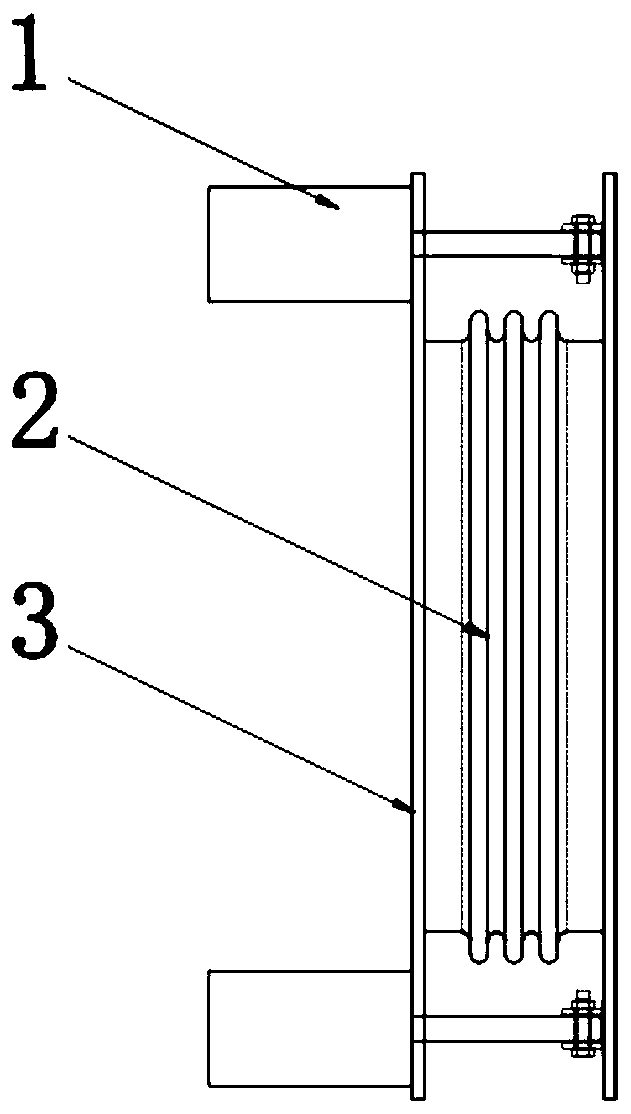

[0022] Such as figure 1 , 2 , 3, 5, and 6, a drive-type telescopic joint, including a telescopic joint main body 2, the two ends of the telescopic joint main body 2 are respectively fixed with end flanges 3, and the end flange 3 at one end A drive mechanism 1 is fixed on it, and the telescopic end of the drive mechanism 1 is connected to the end flange 3 at the other end.

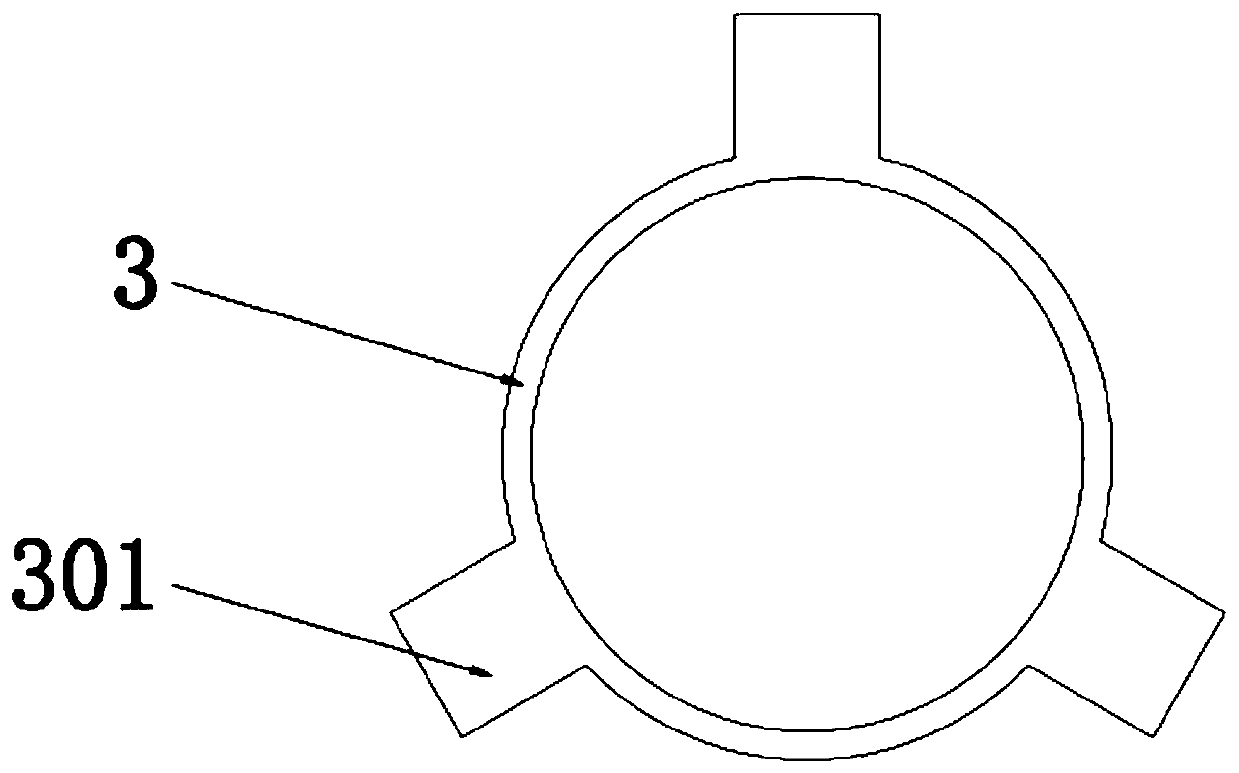

[0023] Connecting ears 301 are arranged at equal intervals on the end flange 3 , and the driving mechanism 1 is mounted on the connecting ears 301 .

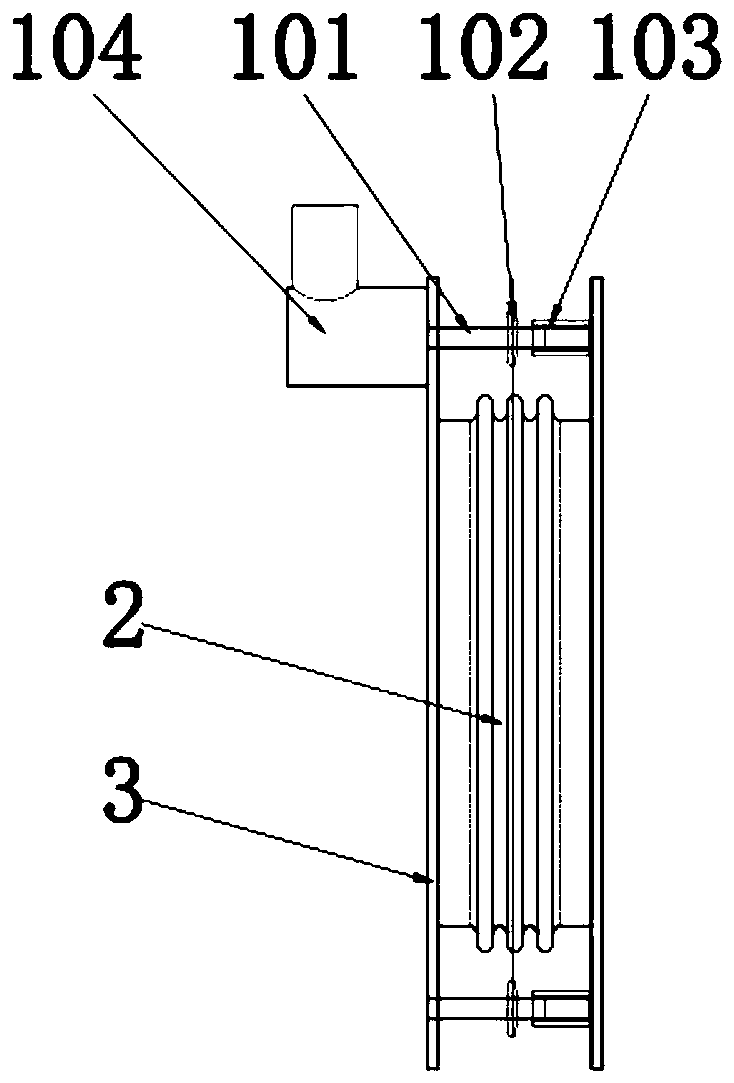

[0024] The driving mechanism 1 is a worm gear reducer 104 . Can be driven manually or electrically.

[0025] The output end of the worm gear reducer 104 is a rotating screw 101, on which a nut sleeve 103 is installed, and the nut sleeve 103 is fixedly connected with the other end flange 3, and the rotating screw 101 A sprocket 102 is also installed on the 101, and the rotating screw mandrels 101 are connected by a chain.

[0026] An application of a driv...

Embodiment 2

[0029] Such as figure 1 , 2 , 4, 5, and 6, a drive-type telescopic joint, including a telescopic joint main body 2, the two ends of the telescopic joint main body 2 are respectively fixed with end flanges 3, and the end flange 3 at one end A drive mechanism 1 is fixed on it, and the telescopic end of the drive mechanism 1 is connected to the end flange 3 at the other end.

[0030] Connecting ears 301 are arranged at equal intervals on the end flange 3 , and the driving mechanism 1 is mounted on the connecting ears 301 .

[0031] The driving mechanism 1 is any one of a cylinder and a hydraulic push rod.

[0032] One end of the air cylinder or hydraulic push rod is fixed on one end flange 3 , and the output end of the air cylinder or hydraulic push rod is fixed on the other end flange 3 .

[0033] An application of a drive type expansion joint, the drive type expansion joint is installed on the guide rail 6, the extended end of the drive type expansion joint is docked with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com