Indoor test system and method of gas impact concrete test block

A concrete test block and indoor test technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low acquisition rate of various types of data, low simulation degree of working conditions and environment, lack of quantification, etc., to improve data acquisition efficiency, Good environmental adaptability and versatility, and the effect of improving the accuracy of test results

Pending Publication Date: 2020-01-24

HENAN POLYTECHNIC UNIV

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The invention discloses an indoor test system for gas impacting concrete test blocks and its use method to solve the problems in the p

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

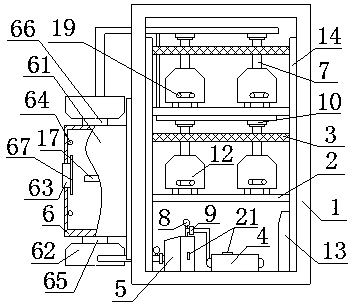

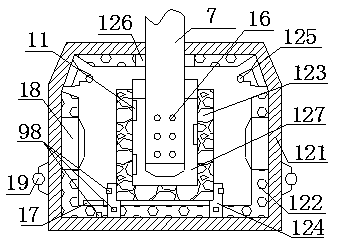

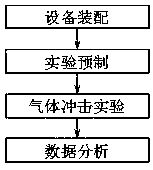

The invention discloses an indoor test system of a gas impact concrete test block. The indoor test system comprises a bearing rack, a partition plate, a bearing skeleton, an air compressor, a gas pressurization pump, a high-pressure gas storage kettle, a high-pressure air pipe, a gas pressure meter, a control switch, a solenoid valve and a test cavity, wherein the partition plate is embedded intothe bearing rack, the bearing rack is partitioned into at least one operation cavity and a control cavity, the air compressor, the gas pressurization pump and the control system are arranged in the control chamber, the high-pressure gas storage kettle is connected with an outer surface of the bearing rack, a front end surface of the high-pressure air pipe communicates with the test cavity, and a rear end surface of the high-pressure air pipe communicates with the high-pressure gas storage kettle. The test method comprises the four steps of equipment assembly, test pre-fabrication, gas impact test and data analysis. On one hand, indoor gas impact test can approach to a site actual condition, so that relatively-safe and effective guidance and reference are provided for site construction operation; and on the other hand, simulation test of different material test blocks under environments with different temperatures, humidity and shaking can be effectively achieved.

Description

technical field [0001] The invention belongs to the technical field of impact test equipment, and in particular relates to an indoor test system for gas impact concrete test blocks and a use method thereof. [0002] technical background [0003] In underground engineering such as tunnels and mining roadways, as well as rock mass excavation such as slopes and foundation pits, in order to overcome the inconvenience of explosive blasting technology, high-pressure gas impact technology is gradually used for blasting operations. In order to improve the efficiency and safety of blasting operations and reduce the cost of blasting operations, it is necessary to use test equipment to detect the characteristics of gas impact blasting operations of materials such as rocks and concrete, and provide safety, Effective guidance. [0004] However, in the actual test and detection process, it is found that there is still a lack of indoor special equipment for gas blasting impact tests on con...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/307G01N3/02

CPCG01N3/02G01N3/307

Inventor 叶红宇杨小林褚怀保朱思源陈真任志强

Owner HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com