Storage battery positive and negative plate wrapping machine

A technology of positive and negative plates and batteries, which is applied in battery assembly machines, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of low production efficiency and achieve the effect of low production efficiency and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

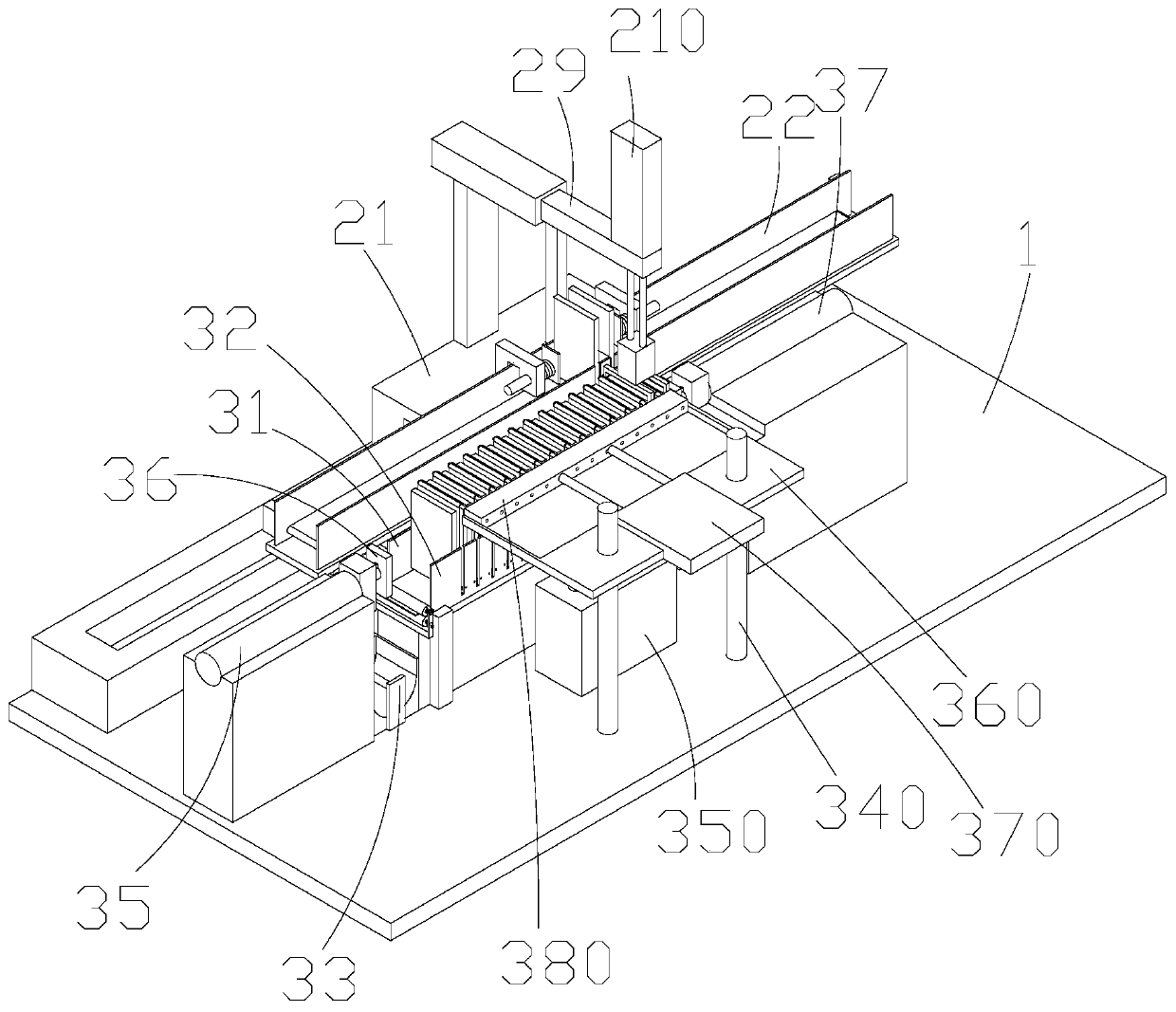

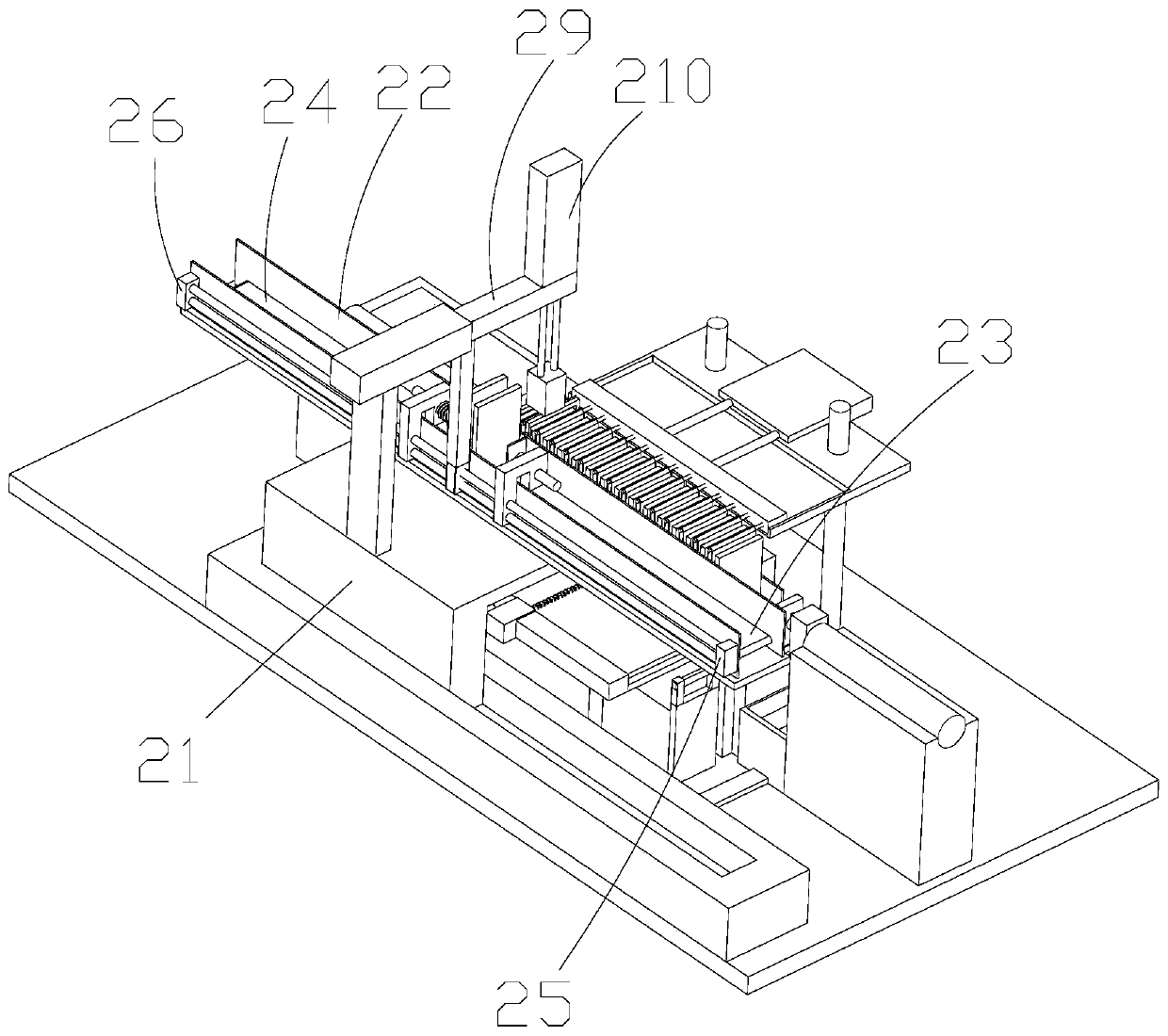

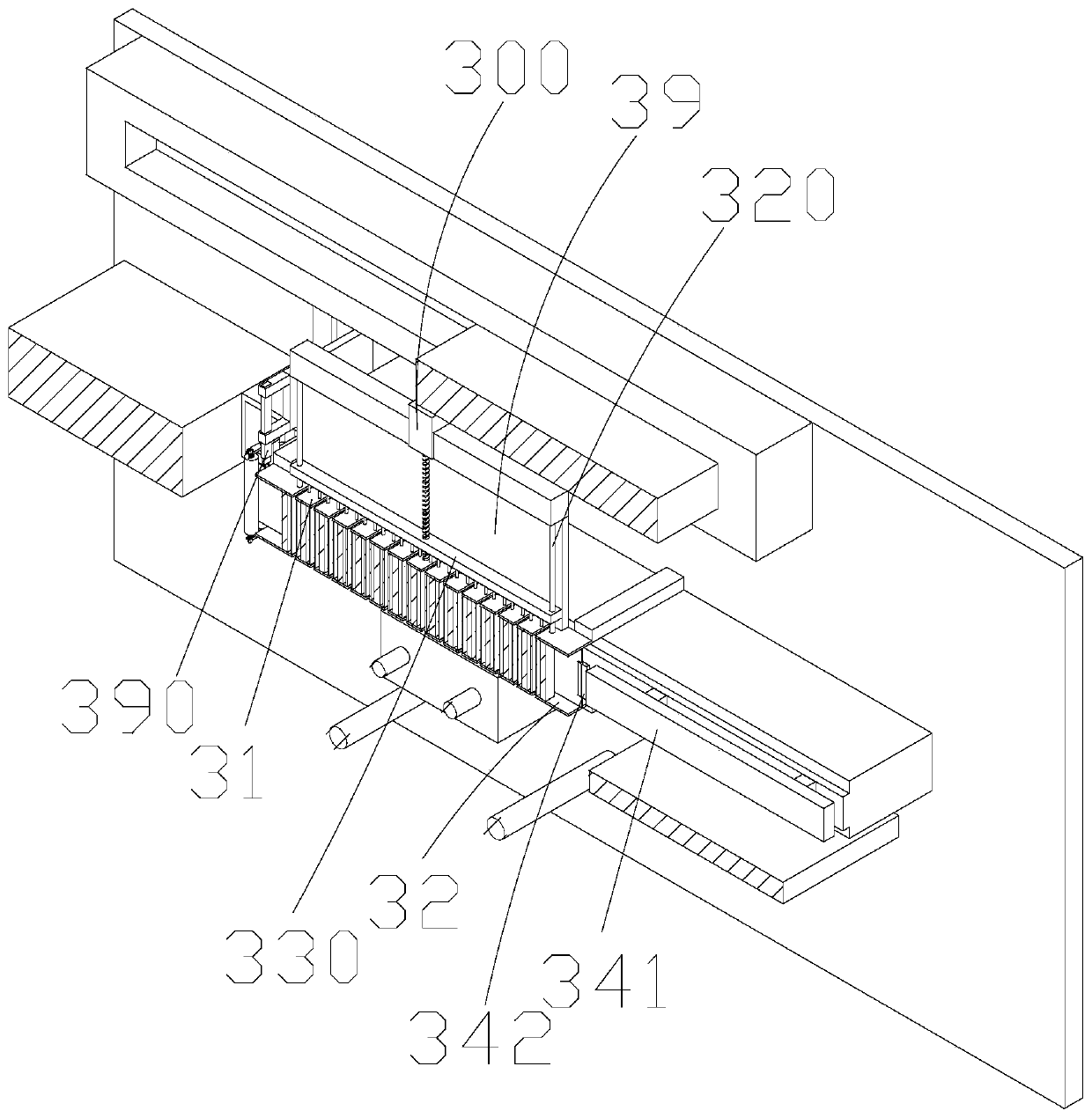

[0024] Such as Figure 1-11 As shown, a battery positive and negative plate wrapping machine includes a workbench 1, a feeding device 2 arranged on the workbench, and a wrapping device 3. The wrapping device includes a fixing seat 30, and a device fixed on the top of the fixing seat. The first baffle plate 31 and the second baffle plate 32, the paper feeding assembly 33 located on the left side of the fixed seat, the paper pulling assembly 34 located on the upper surface of the fixed seat, the first air cylinder 35 arranged on the workbench, the first air cylinder arranged on the first air cylinder The first push block 36 on the telescopic rod, the second cylinder 37 that is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap