Bearing housing for turbomachine, and turbomachine having bearing housing

A bearing housing, bearing axis technology, applied to components of pumping devices for elastic fluids, bearing cooling, bearing components, etc., can solve the problem of increased wear, high bearing housing cost, insufficient and expensive cooling technology, etc. problem to achieve the effect of increasing the total surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

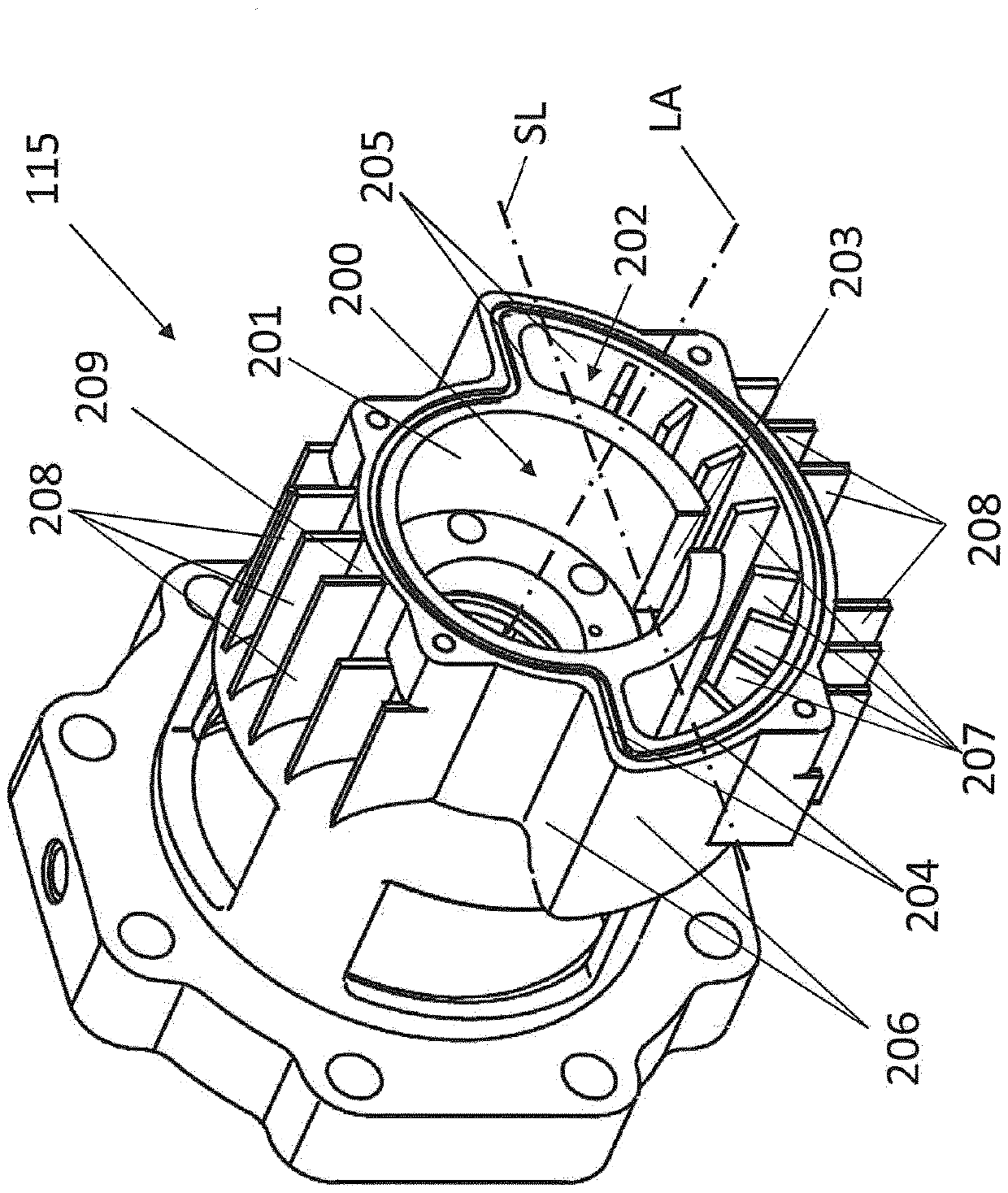

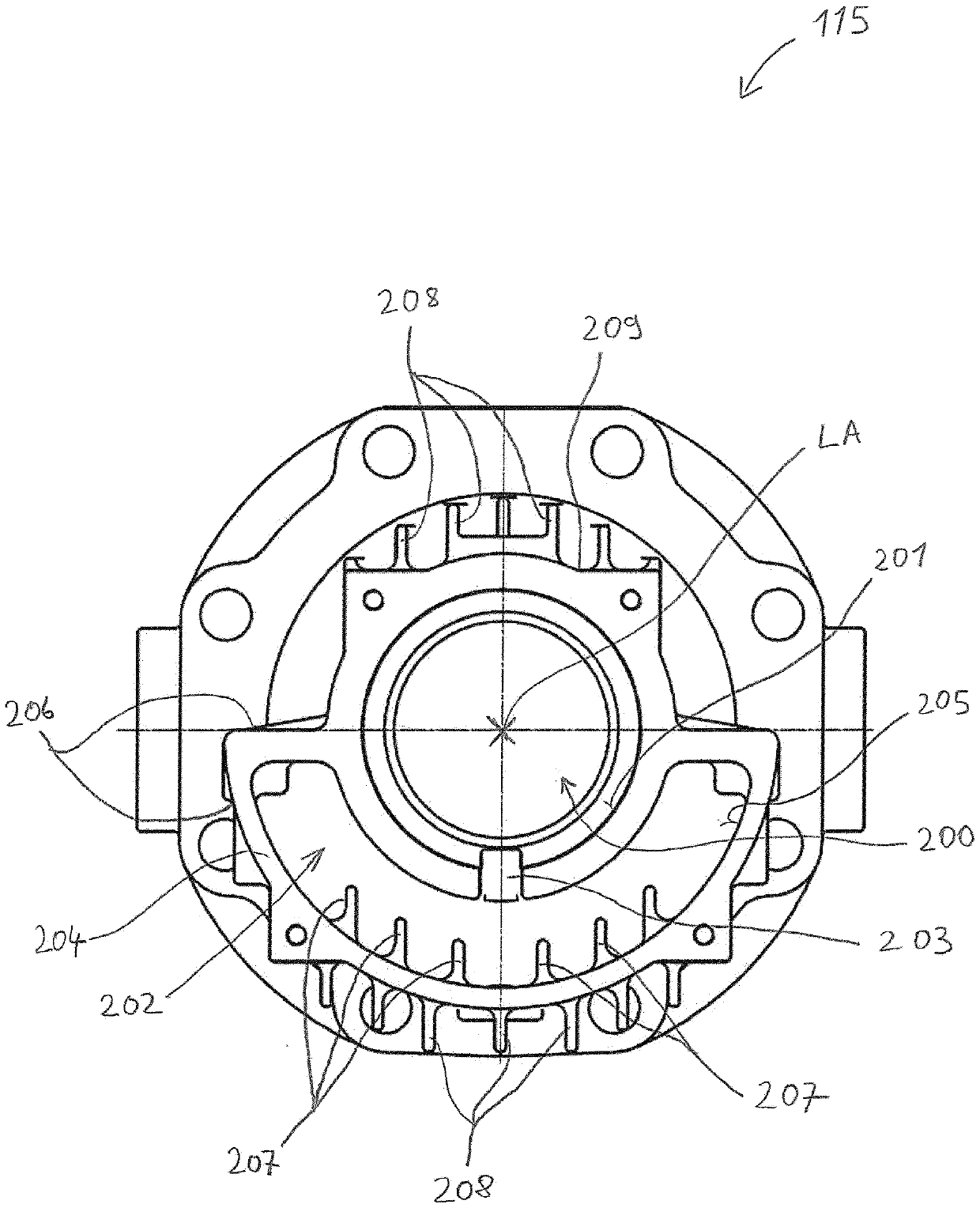

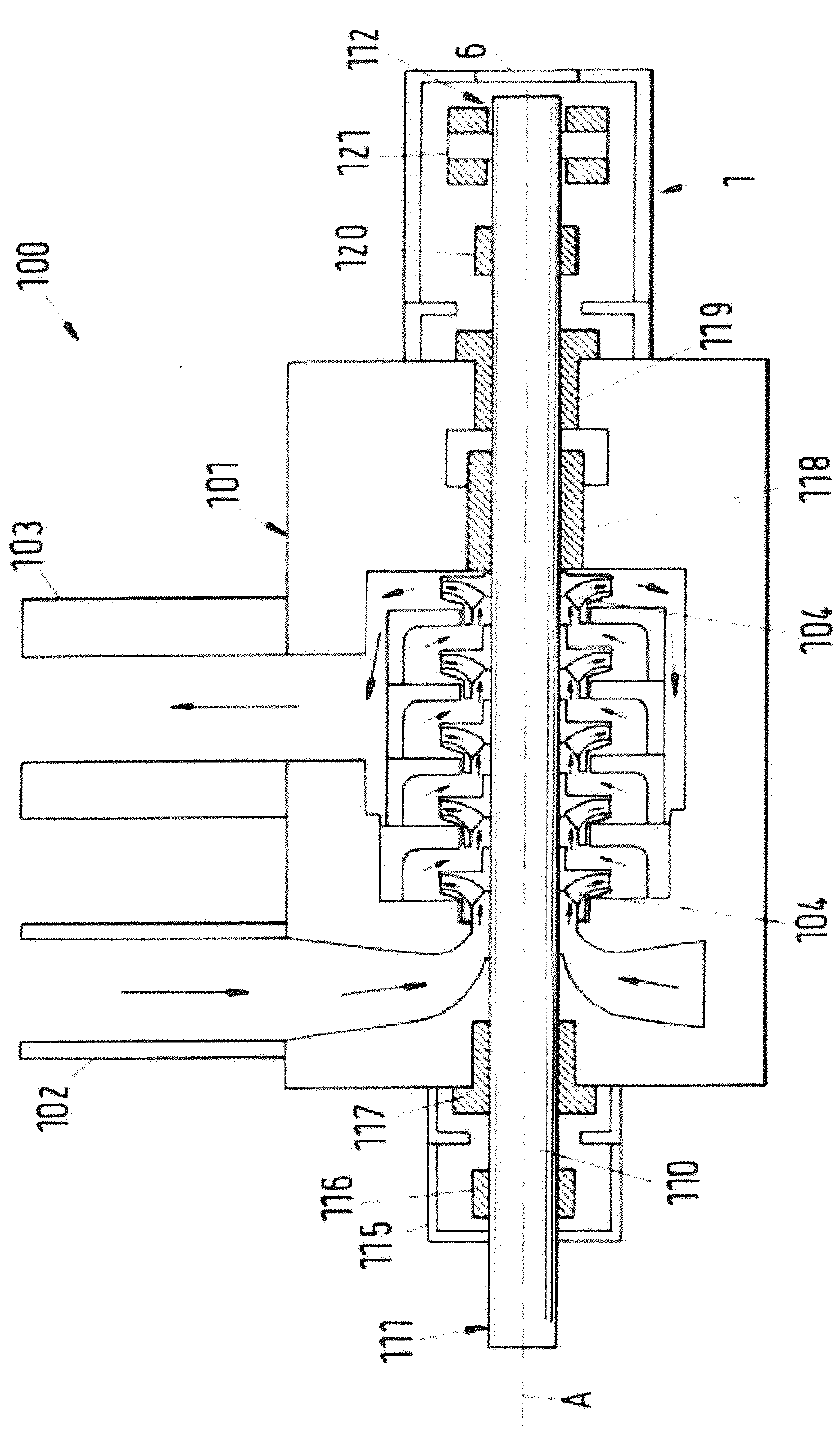

[0030] figure 1 A cross-sectional view of an embodiment of a flow machine according to the invention is shown, the flow machine being denoted with the reference numeral 100 in its units. An example of a flow machine 100 is a centrifugal pump 100 for conveying fluids such as water or crude oil or multiphase liquids. Obviously, the present invention is neither limited to figure 1 The centrifugal pump 100 shown in , is also not limited to the centrifugal pump itself, but generally refers to the flow machine 100 . For example, flow machine 100 may also be another type of pump, compressor, fan, expander, or turbine.

[0031] The centrifugal pump 100 comprises a housing 101 which may consist of a plurality of housing parts connected to each other to form the housing 101 . The housing 101 of the centrifugal pump 100 includes an inlet 102 through which the fluid to be delivered enters the pump 100 , and an outlet 103 for discharging the fluid. At least one impeller 104 is disposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com