Shoemaking refrigerating machine

A technology for refrigerators and shoes, applied in shoe uppers, footwear, applications, etc., can solve the problems of concentration of cold air, affecting the quality of shoes, poor freezing effect, etc., to avoid rust damage and good freezing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

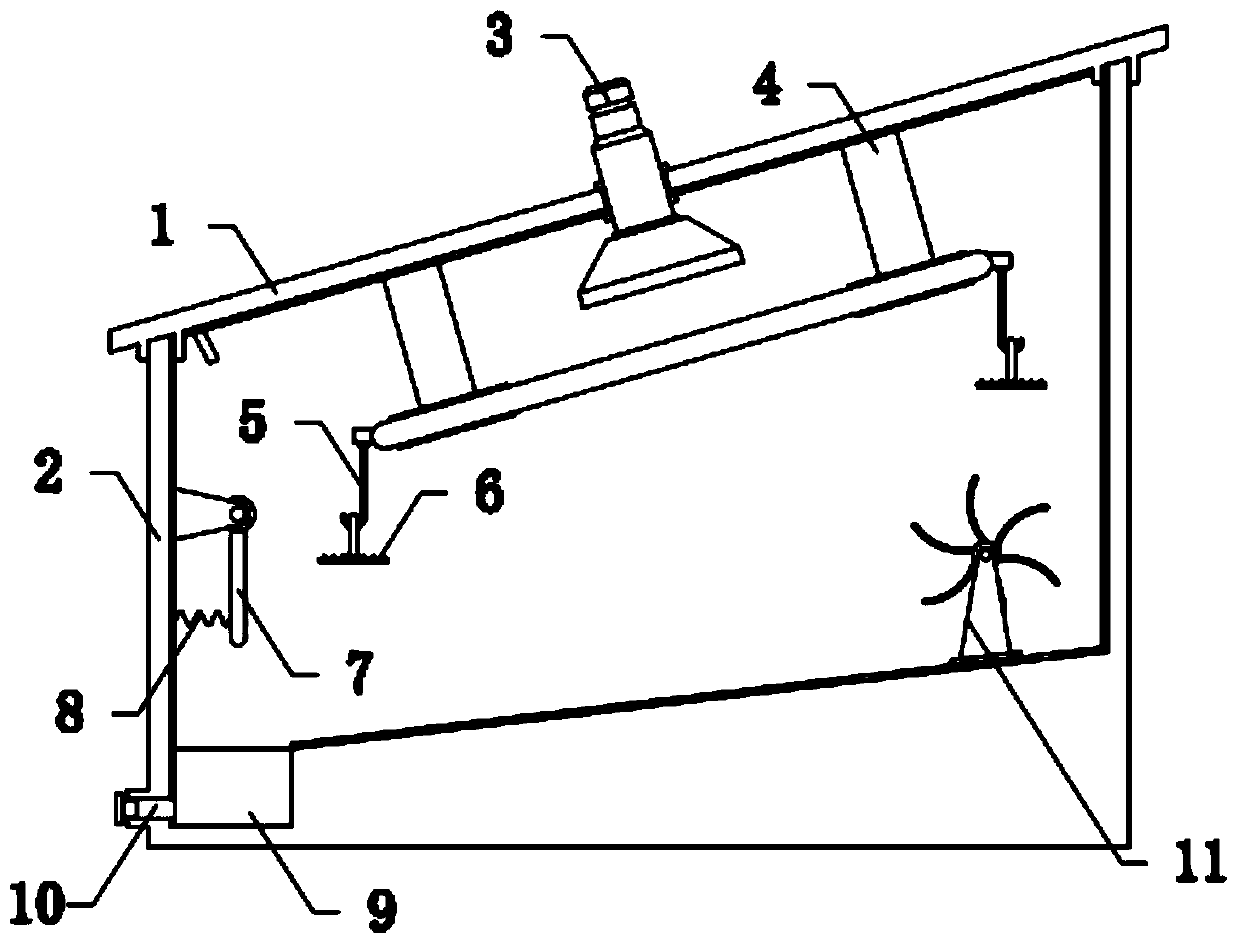

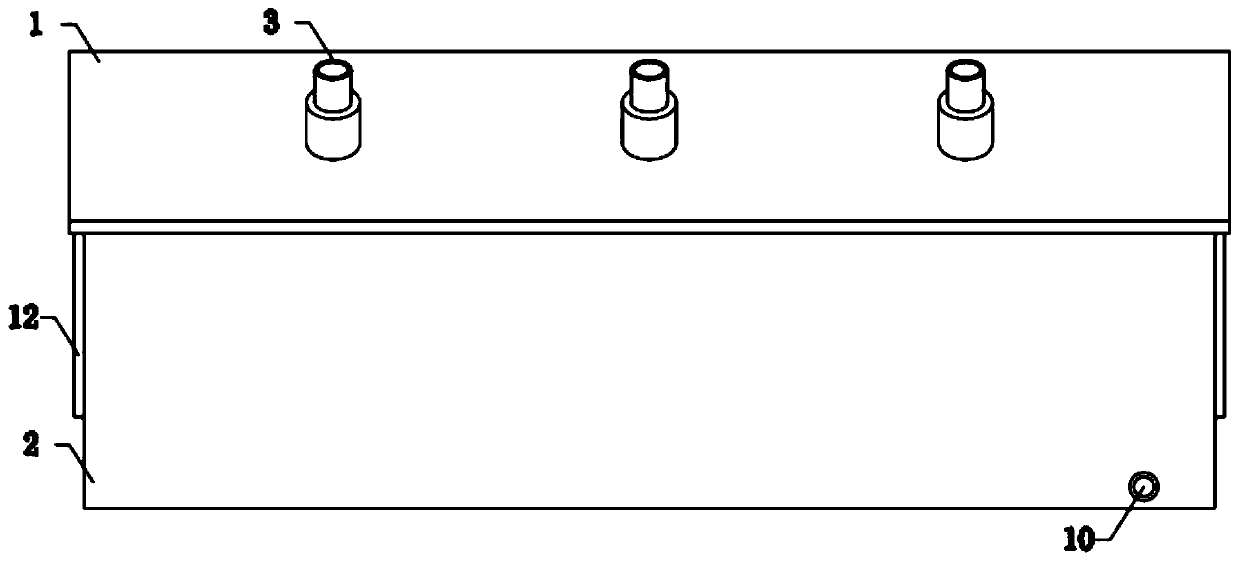

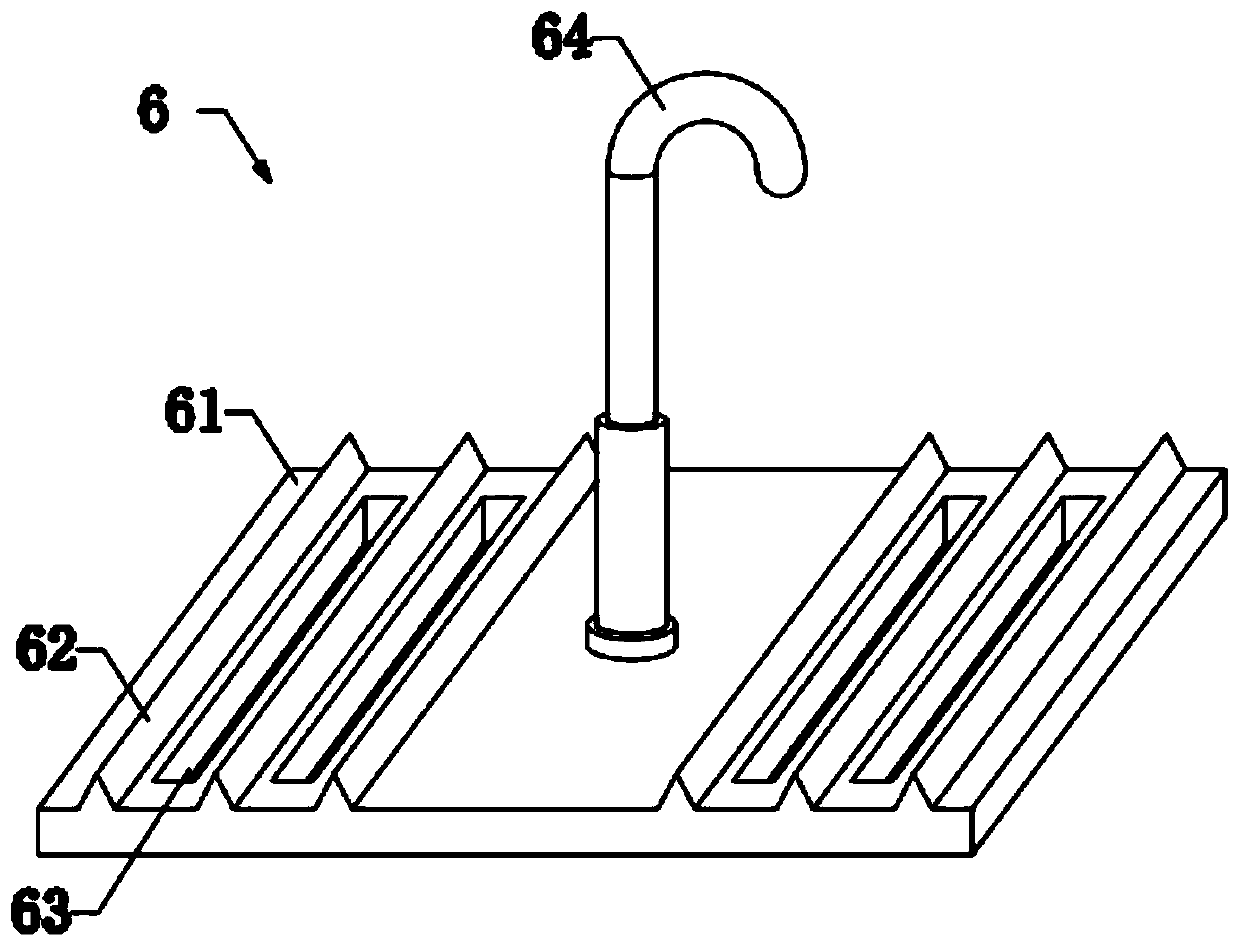

[0023] see Figure 1-3 , the present invention provides a technical solution: a refrigerator for shoemaking, comprising a top cover 1 and a support frame 2 arranged on the lower surface of the top cover 1, a cold air output head 3 is uniformly installed on the top cover 1, and the cold air output head 3 extends to the lower side of the top cover 1, the lower surface of the top cover 1 is fixedly connected with a transmission belt mechanism 4 by screws, the transmission belt mechanism 4 is provided with a hook assembly 5, and a shoe support frame 6 is attached to the hook assembly 5 to support A deflector 7 is connected to the side wall of the inner cavity of the frame 2 through a pin shaft, and a buffer spring 8 is supported between the bottom end of the deflector 7 and the inner cavity side wall of the supporting frame 2, and the bottom of the inner cavity of the supporting frame 2 A condensed water collecting tank 9 is provided, and a condensed water discharge port 10 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com