Balance weight structure of hoist

A technology of counterweight and elevator, applied in the direction of lifting equipment, transportation and packaging in mines, can solve the problems of easy breakage, loss, damage, etc., and achieve the effect of not easy to break and prevent corrosion and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention provides a counterweight structure design of an elevator, especially a counterweight structure design that is not easy to be rusted or broken during transportation, and the price can be greatly reduced.

[0032] In order to enable your examiner to have a further understanding and understanding of the purpose, features and effects of the present invention, please cooperate with the accompanying drawings to describe in detail as follows:

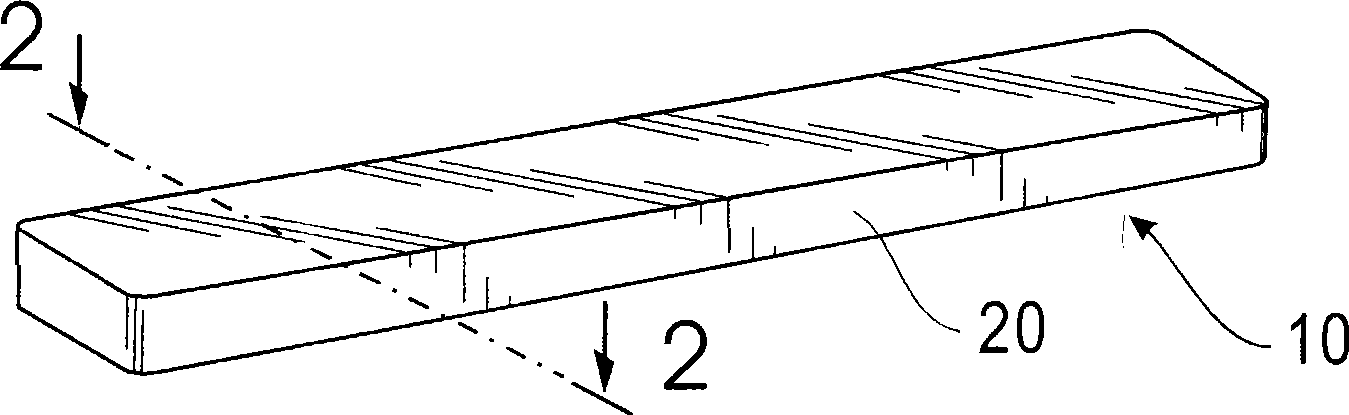

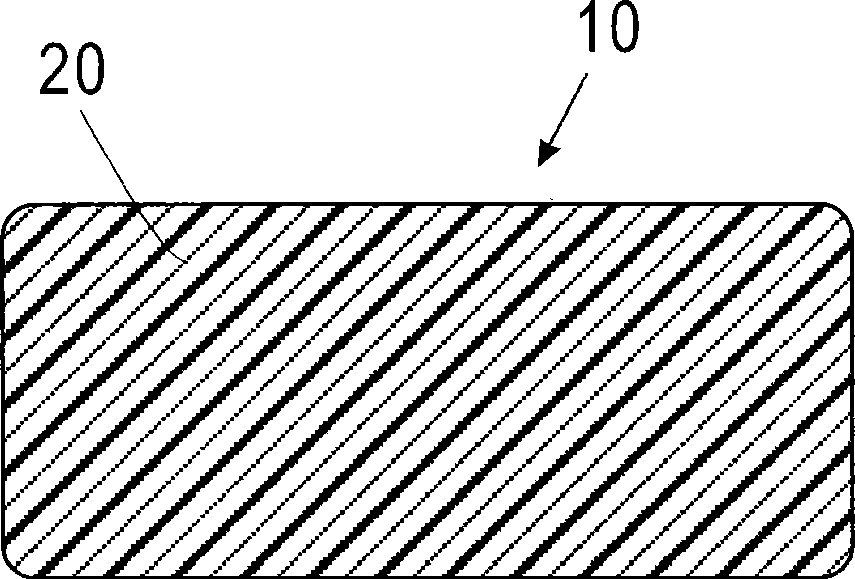

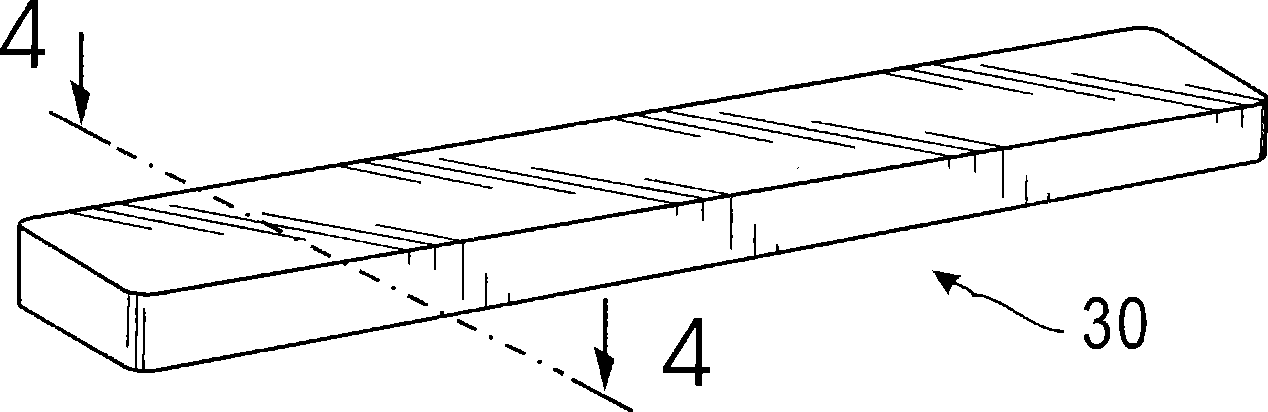

[0033] refer to image 3 Shown is a three-dimensional schematic diagram of one embodiment of the present invention, the elevator is used as a means of transportation between floors of high buildings, and the balance structure is used as a balance elevator during the initial start-up process, which can reduce the output and avoid instantaneous If the power source is damaged due to excessive force, or can make the elevator move more smoothly, the balance structure described is generally a solid rectangular body with a heavy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com