On-line plate blank weighing device

A weighing device and slab technology, applied in the direction of measuring devices, optical devices, detailed information of weighing equipment, etc., can solve the problems of easy corrosion and damage, difficult maintenance, and narrow space of the base frame of the scale body. Spacious space, simplified weighing platform structure, and the effect of maintaining weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

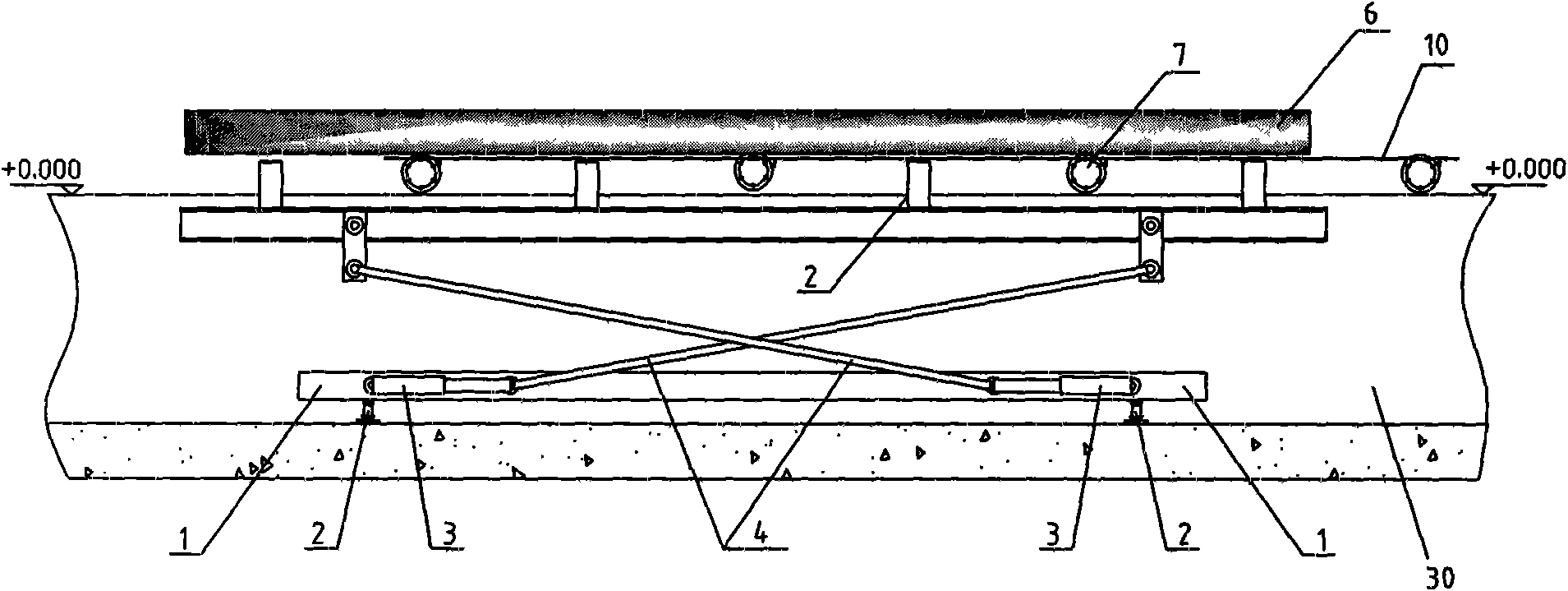

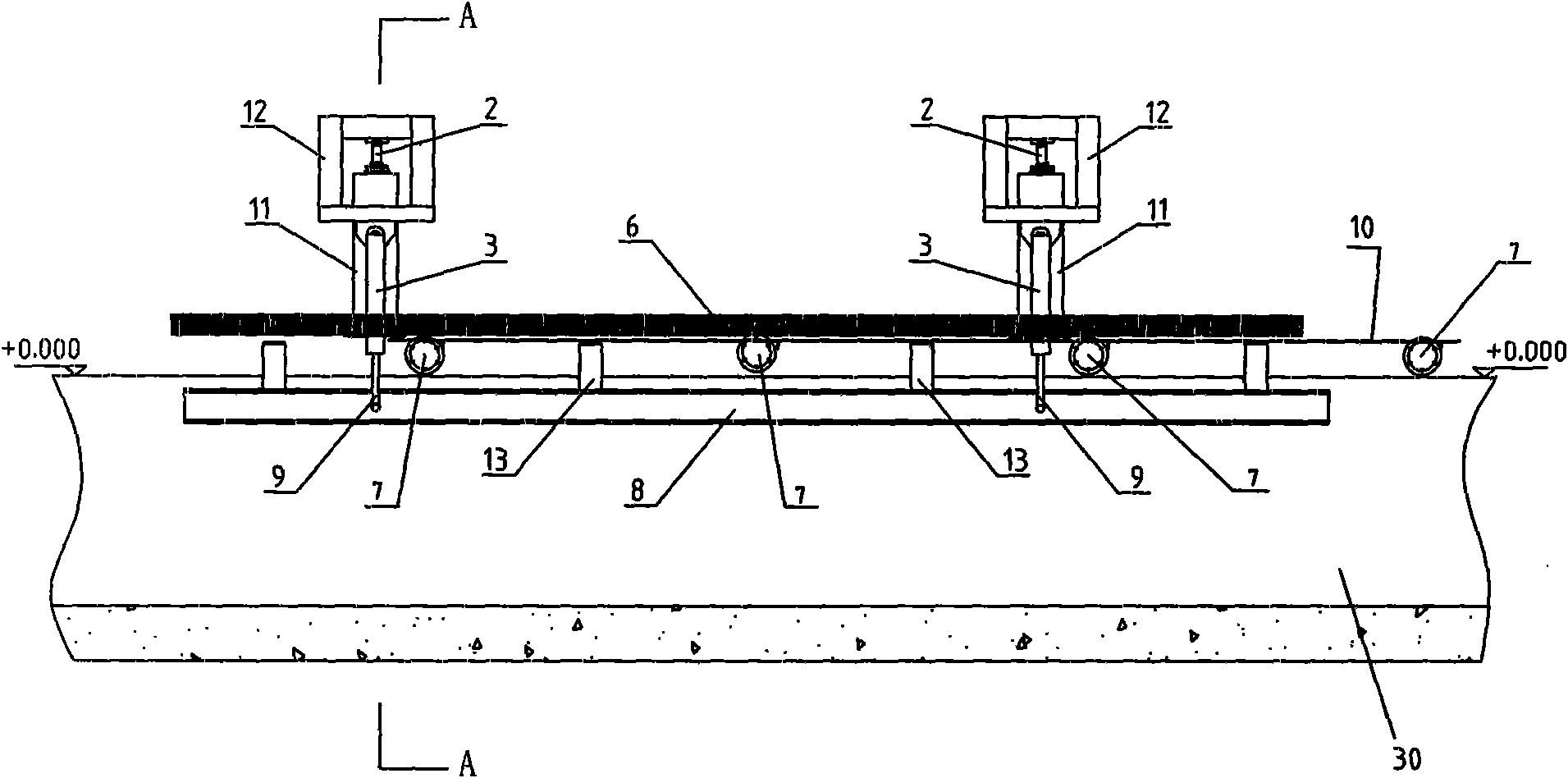

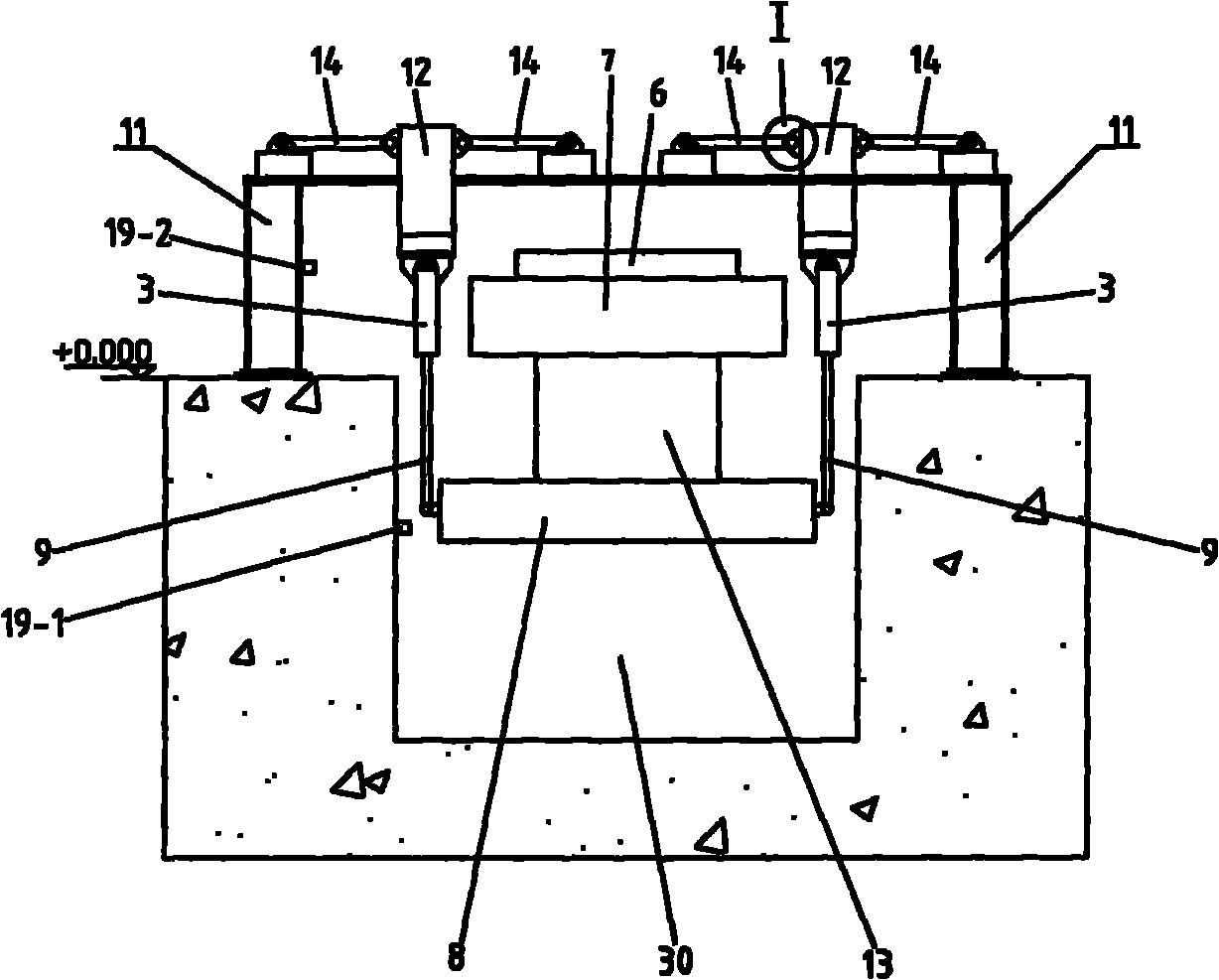

[0025] The online slab weighing device of this embodiment is as figure 2 , image 3 and Figure 4 As shown, including the weighing platform 8 in the pit 30 below the roller table 7, the hydraulic cylinder 3 with the piston rod 9, the pressure sensor 2, the cooling water pipe 10 and the control display device (not shown), the hydraulic cylinder 3 The signal input end and the signal output end of the pressure sensor 2 are respectively connected with corresponding ports of the control display device. A pair of gate-shaped supports 11 straddling the roller table 7 are arranged respectively on the floor on both sides of the roller table 7 . There are four pressure sensors 2, which are respectively fixed on the two ends of the crossbeam of a pair of gantry brackets 11; four pressure sensors 2 are respectively equipped with four annular connecting frames 12; there are four hydraulic cylinders 3, which are respectively fixed on four On the ring connection frame 12. One end of the...

Embodiment 2

[0032]The online slab weighing device of this embodiment is an improvement on the basis of the first embodiment, and its structure is basically the same as that of the first embodiment, as Image 6 , Figure 7 and Figure 8 As shown, the difference is: 1) the two sides of the weighing platform 8 are respectively shaped on four protruding corner frames 15; The four corner frames 15 extend horizontally into the four notches 16 respectively; 3) The door-shaped brackets 11 are two pairs of four, and do not cross the roller table 7, but are respectively placed on the floor on both sides of the roller table 7 ; 4) Four pressure sensors 2 are respectively fixed on the crossbeams of four gantry brackets 11, four annular connecting frames 12 and four hydraulic cylinders 3 on them are located above the four notches 16, and the piston rod 9 stretches out the hydraulic pressure. One end of the oil cylinder 3 vertically extends into the notch 16 and is connected with the corner frame 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com