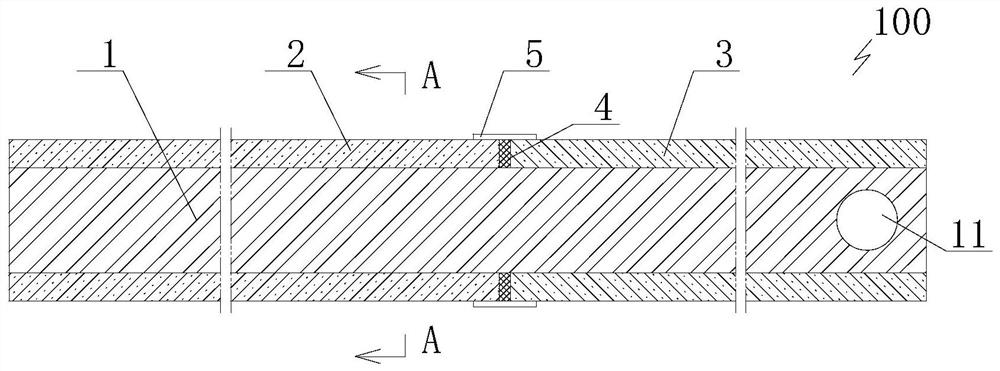

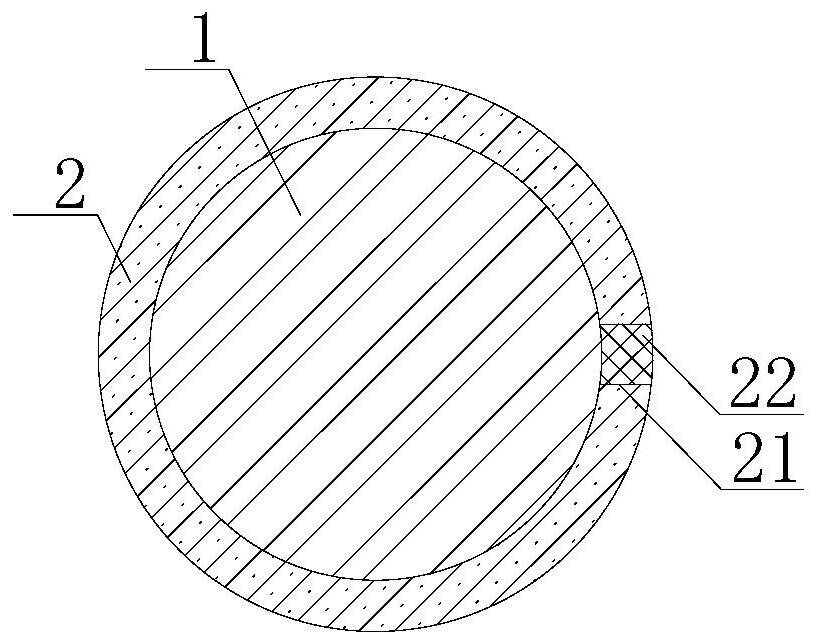

Cathode cable structure for impressed current cathodic protection device of thermal production well

A technology of impressed current and cathodic protection, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as high-temperature oxygen corrosion of copper or aluminum cores, potential safety hazards, aging of insulation layers, etc., to avoid corrosion damage, improve replacement efficiency, The effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

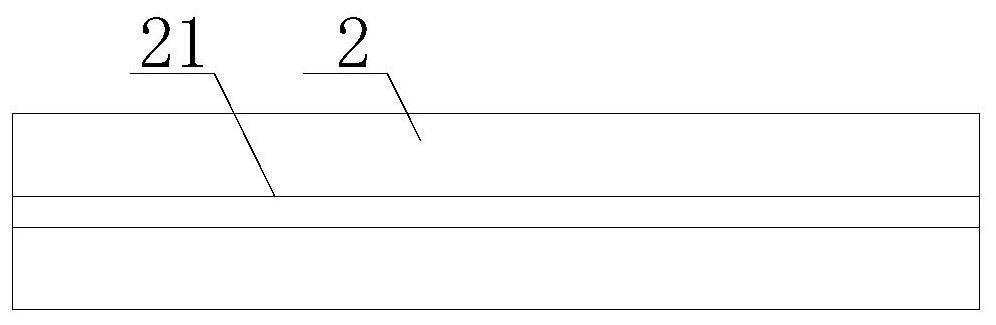

[0033] In order to understand the technical features, objects and effects of the present invention, specific embodiments of the present invention will be described with reference to the drawings.

[0034] DETAILED DESCRIPTION OF THE INVENTION The embodiments of the invention are intended to be utilized for the purposes of the present invention, without understanding of the invention. Under the teachings of the present invention, those skilled in the present invention may be considered as they belong to the scope of the invention. It should be noted that when the element is referred to as "set to" another element, it can be directly in another element or may also exist. When an element is considered to be "connected" another element, it can be directly connected to another element or may exist at the same time. The term "installation", "connected", "connection" should be broadly understood, for example, can be mechanically connected or electrically connected, or in communication in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Temperature tolerance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com