Data acquisition and transmitting device for detecting wear amount of lining plate of mill

A technology of data acquisition and emission devices, applied in the field of mills, can solve problems such as cumbersome operation, high cost, and high technical requirements for installation, and achieve the effects of clear division of labor, improved utilization, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following embodiments.

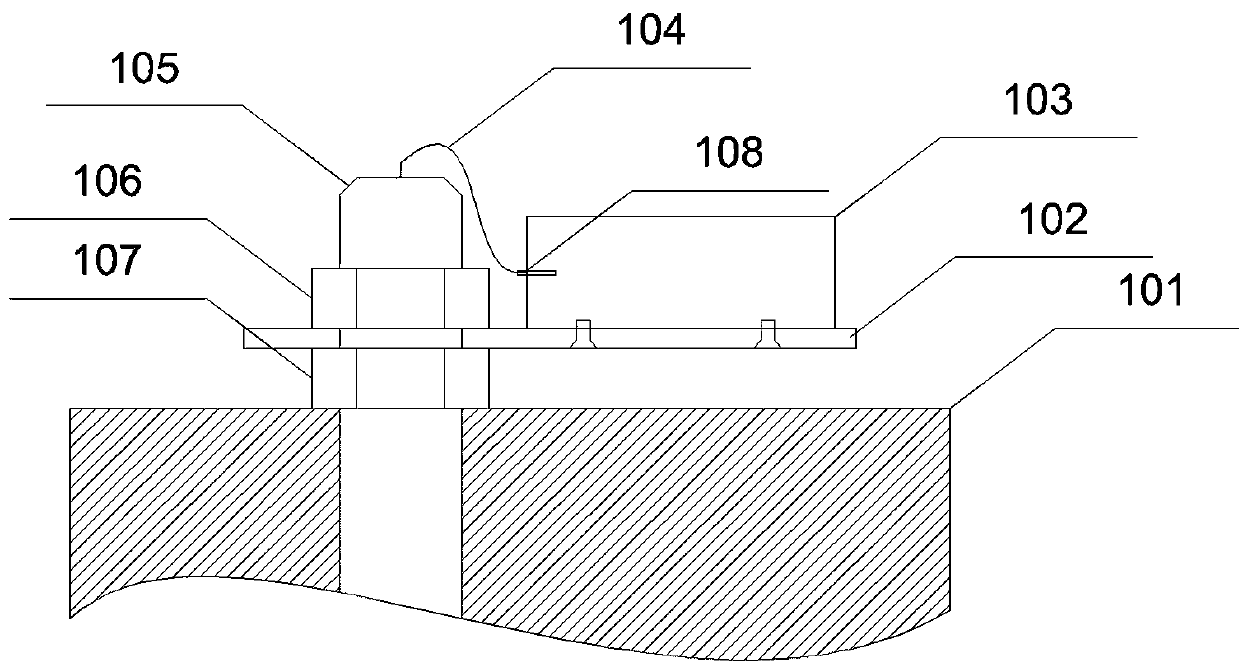

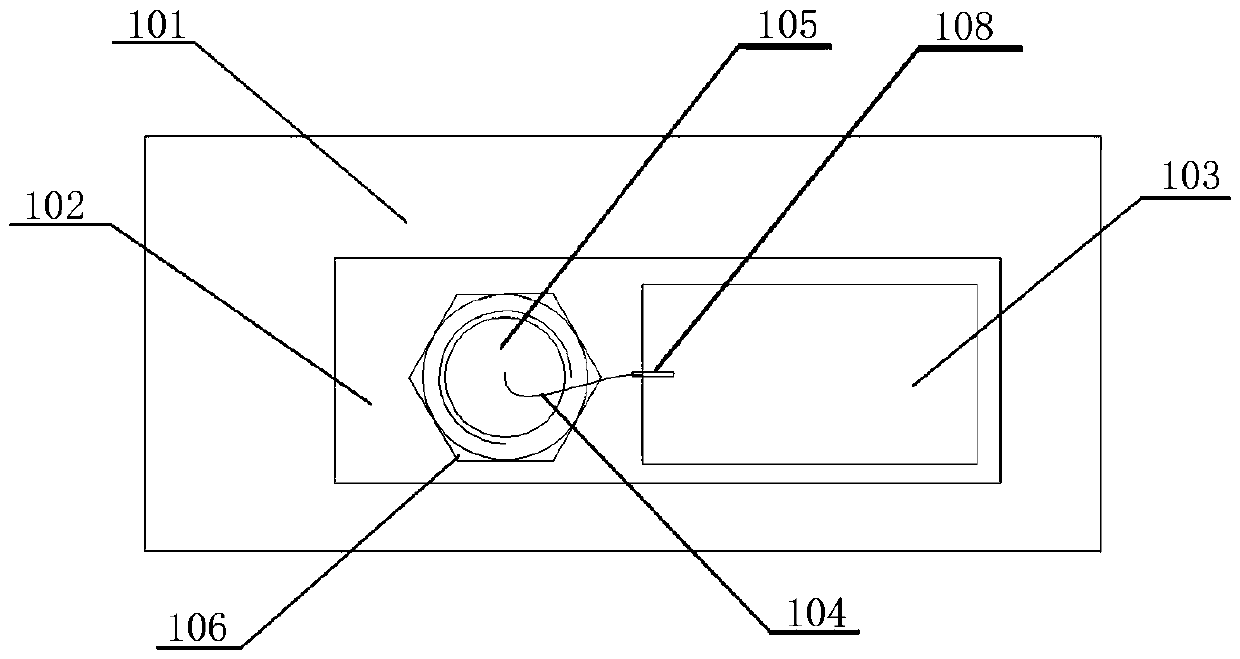

[0022] As shown in the figure, a data acquisition and transmission device for detecting the amount of wear of the liner of the mill, including a detection bolt 105 arranged in the mill cylinder 101, a mounting plate 102, a data processor 103, and a connecting wire 104, An outer mounting nut 106 , an inner mounting nut 107 and a wire mounting head 108 .

[0023] Wherein, one end of the detection bolt 105 passes through the mill cylinder 101 and the mill liner in turn, and is flush with the inner edge of the mill liner, and the other end of the detection bolt 105 extends out of the mill cylinder 101 to detect The inside of the bolt 105 is a hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com