Automatic cutting machine for fiber yarns

A fiber filament and cutting machine technology, which is used in the transportation of filamentous materials, metal processing, thin material processing, etc., can solve the problems of waste, loss of fiber filaments, time-consuming and laborious, so as to protect physical and mental health and reduce contact opportunities. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

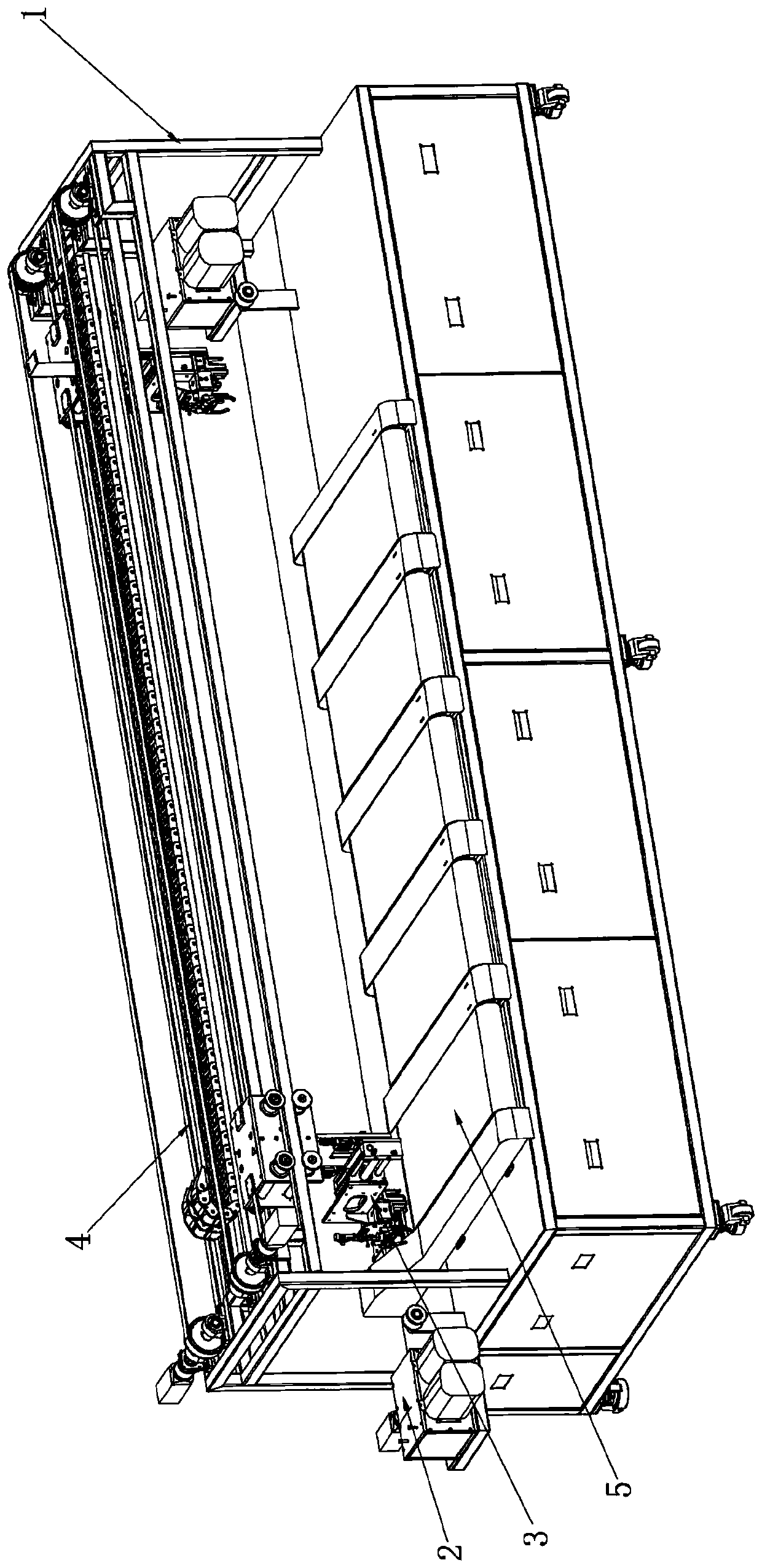

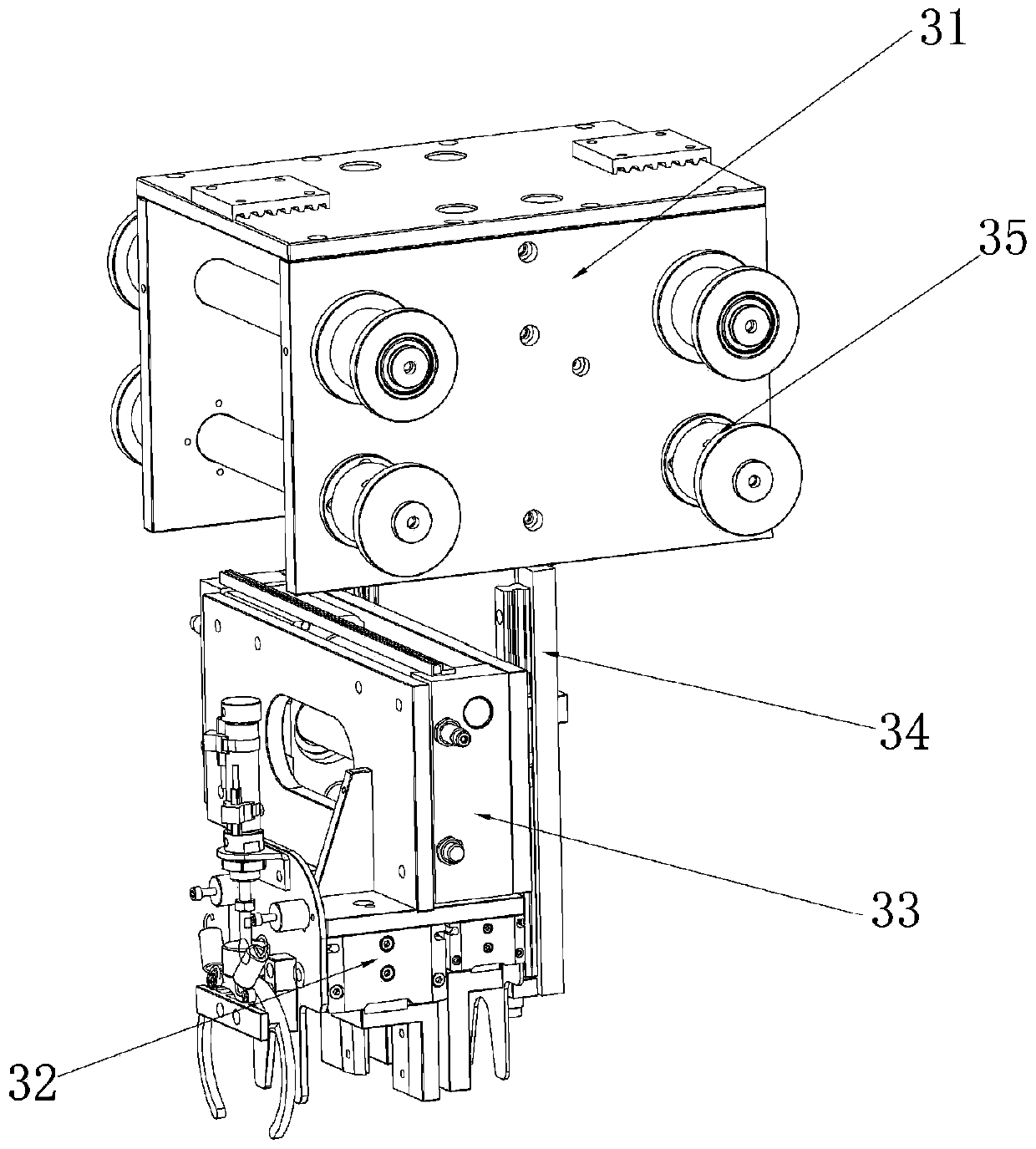

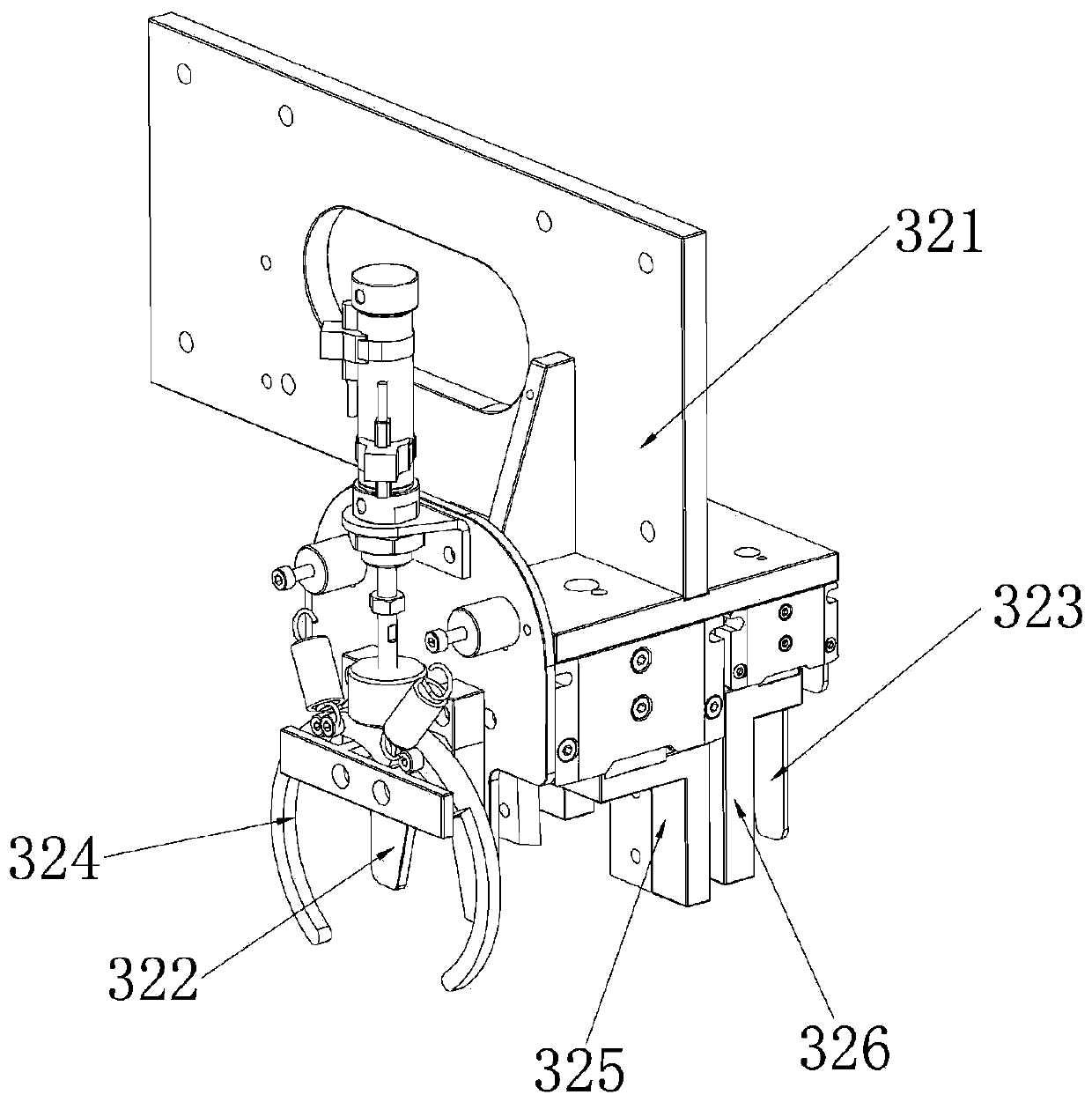

[0026] Such as figure 1 As shown, the fiber filament automatic cutting machine described in this embodiment includes a frame 1 and a feeding device 2, a manipulator 3, a reciprocating mechanism 4 and a conveying mechanism 5 arranged on the frame 1; the feeding device 2 has Two, respectively located at the front and rear ends of the frame 1, the fiber filaments are conveyed from the feeding device 2 at the rear end to the feeding device 2 at the front end, and the speed of the two feeding devices 2 conveying the fiber filaments is related to the fiber spinning The spinning speed of the machine matches the spinning speed; there are two manipulators 3, which slide on two parallel guide rails of the frame 1, and are located between the two feeding devices 2, and each manipulator 3 is connected with a reciprocating The motion mechanism 4, two reciprocating mechanisms 4 are paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com