Purified smelting process of a nickel-based superalloy rich in active elements

A technology of nickel-based superalloy and active elements, which is applied in the field of metal smelting and casting, can solve the problems of unfavorable casting quality control, unclear influence, sand sticking, etc., achieve low gas and impurity element content, uniform composition, and improve purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

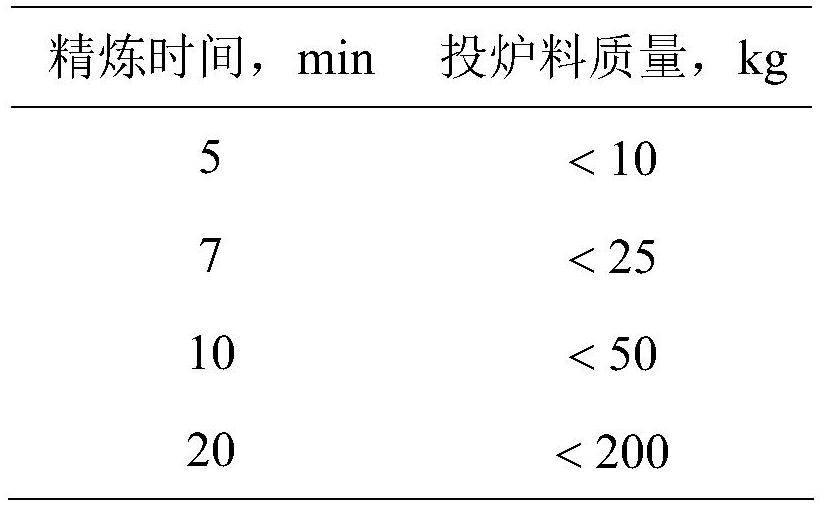

[0036] The preparation of the master alloy ingot comprises the following steps (a)-(e):

[0037] (a) prepare each element raw material according to the chemical composition of the master alloy ingot;

[0038] (b) Put the Ni, Cr, and C elemental raw materials into the crucible, wherein: the Cr elemental material is placed in the middle of the crucible and surrounded by the Ni elemental material; the C elemental material is placed at the bottom of the crucible, and each raw material is pre-processed before being added to the crucible to be less than φ1mm particle;

[0039] (c) Melt the Ni, Cr and C raw materials in the crucible in a vacuum induction furnace, and ensure that the vacuum degree in the furnace is less than 10 during the smelting period -2 Pa, after the melt surface is stable, high temperature refining is carried out;

[0040] (d) After high-temperature refining, the temperature is naturally lowered, and when the temperature of the melt is lowered to the vicinity of ...

Embodiment 1

[0051] In this embodiment, the smelting master alloy is K417G, and the smelting quality is 10kg.

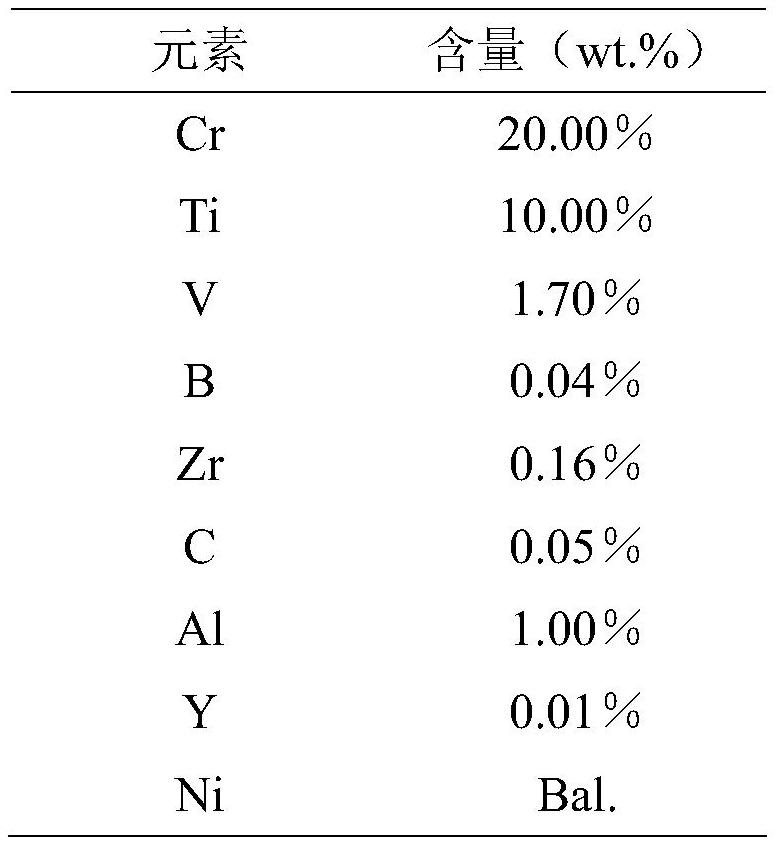

[0052] The design composition of master alloy-1 is shown in Table 2:

[0053] Table 2

[0054]

[0055] Master alloy preparation process (smelting in vacuum induction furnace, vacuum degree higher than 10 -2 Pa):

[0056] (1) High temperature refining: 1450℃×5min;

[0057] (2) After the melt temperature drops to 1420°C, add V, Zr, B, Y, Al and other elements in turn, and let stand for 1 min after the liquid level is stable;

[0058] (3) Low temperature refining: 1330℃×5min;

[0059] (4) Casting temperature: 1360°C.

[0060] The O content in Master Alloy-1 was measured to be 28 ppm, and the N content was 3 ppm.

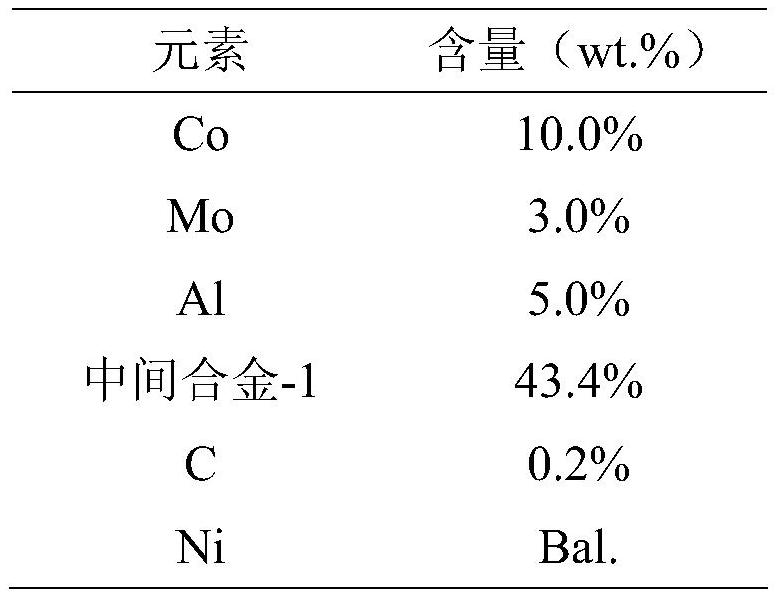

[0061] The ingredients of the master alloy are shown in Table 3:

[0062] table 3

[0063]

[0064] Master alloy smelting process (smelting in vacuum induction furnace, vacuum degree higher than 10 -2 Pa):

[0065] (1) High temperature refining: 1500℃×5min...

Embodiment 2

[0071] This embodiment smelts the master alloy grade K417G, and the smelting quality is 50kg.

[0072] The design composition of master alloy-2 is shown in Table 4:

[0073] Table 4

[0074]

[0075]

[0076] Master alloy preparation process (smelting in vacuum induction furnace, vacuum degree higher than 10 -2 Pa):

[0077] (1) High temperature refining: 1450℃×10min;

[0078] (2) After the melt temperature drops to 1420°C, add V, Zr, B, Y, Al and other elements in turn, and let stand for 3 minutes after the liquid level is stable;

[0079] (3) Low temperature refining: 1330℃×10min;

[0080] (4) Casting temperature: 1360°C.

[0081] The O content in Master Alloy-2 was measured to be 29 ppm, and the N content was 4 ppm.

[0082] The ingredients of the master alloy are shown in Table 5:

[0083] table 5

[0084]

[0085] Master alloy smelting process (smelting in vacuum induction furnace, vacuum degree higher than 10 -2 Pa):

[0086] (1) High temperature refin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com