Suspension bridge ultra-long main cable strand cable relaxing machine

A suspension bridge and cable laying machine technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of complex structure, manufacturing, operation, huge equipment, high design and manufacturing costs, shorten the time for replacing cable drums, improve Construction efficiency, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The utility model relates to a cable-laying machine for super-long main cable strands of a suspension bridge.

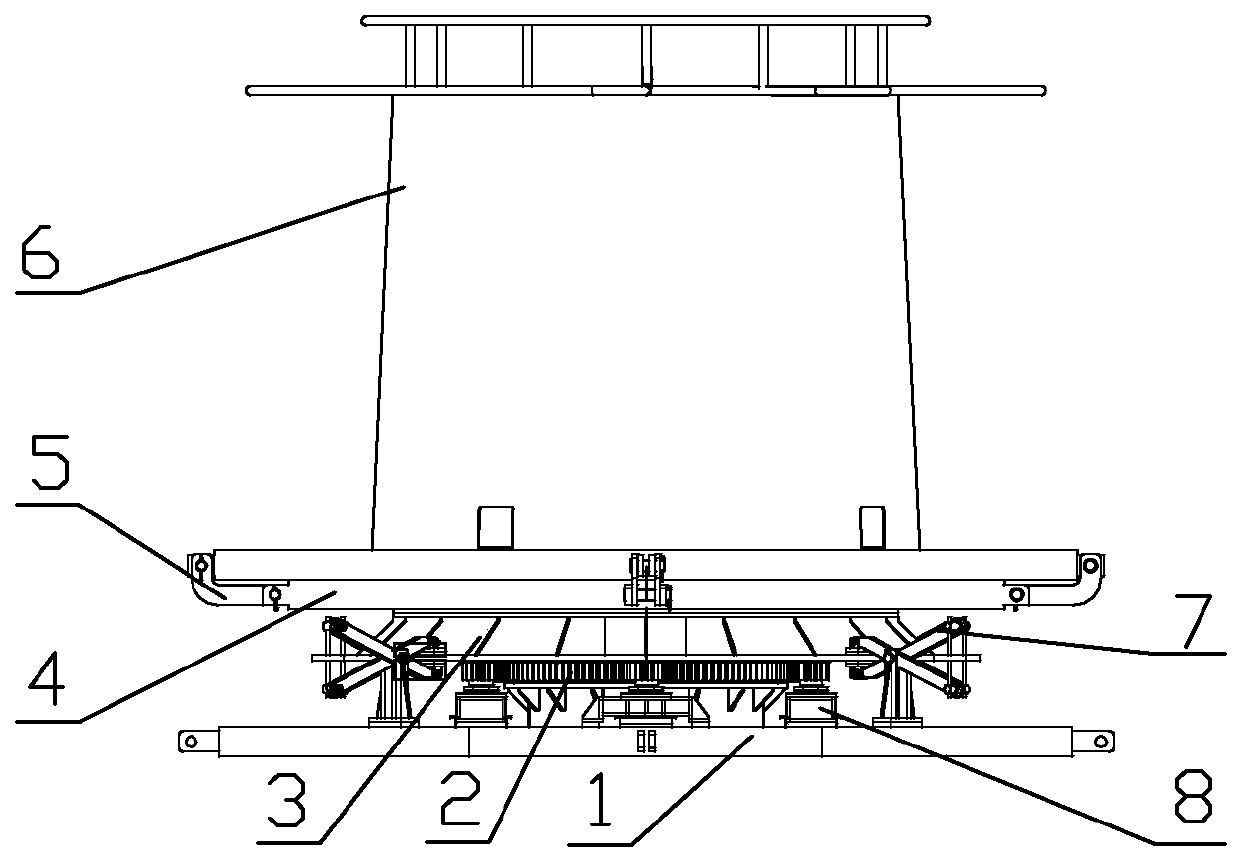

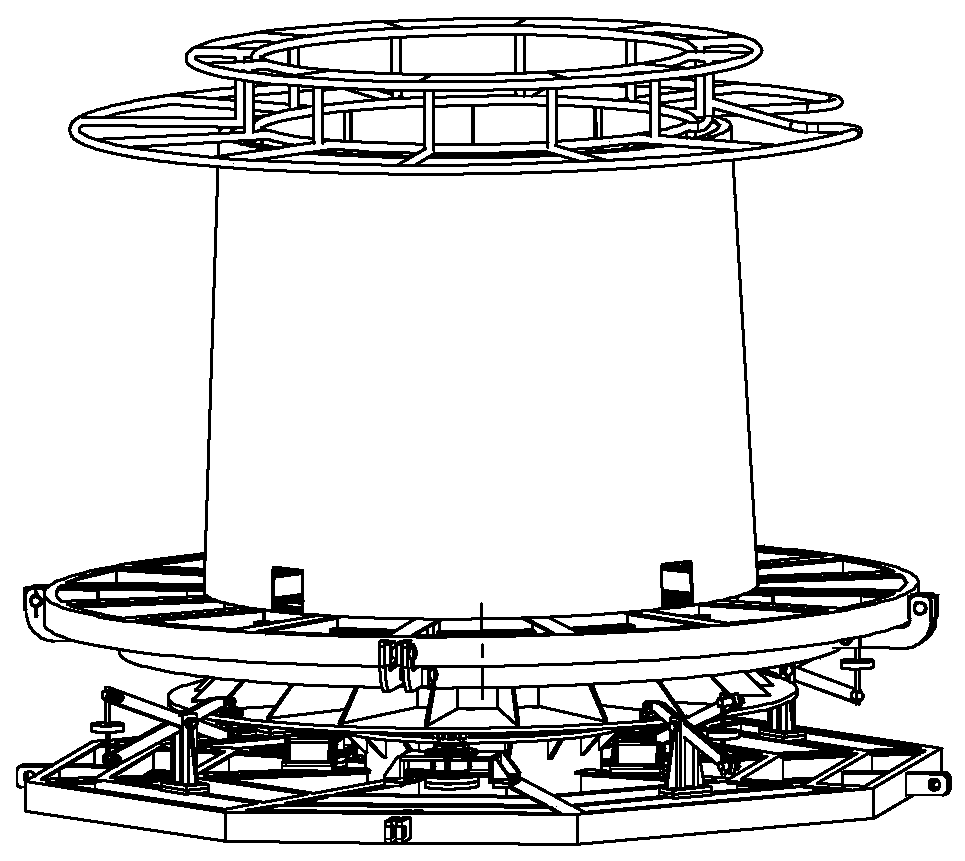

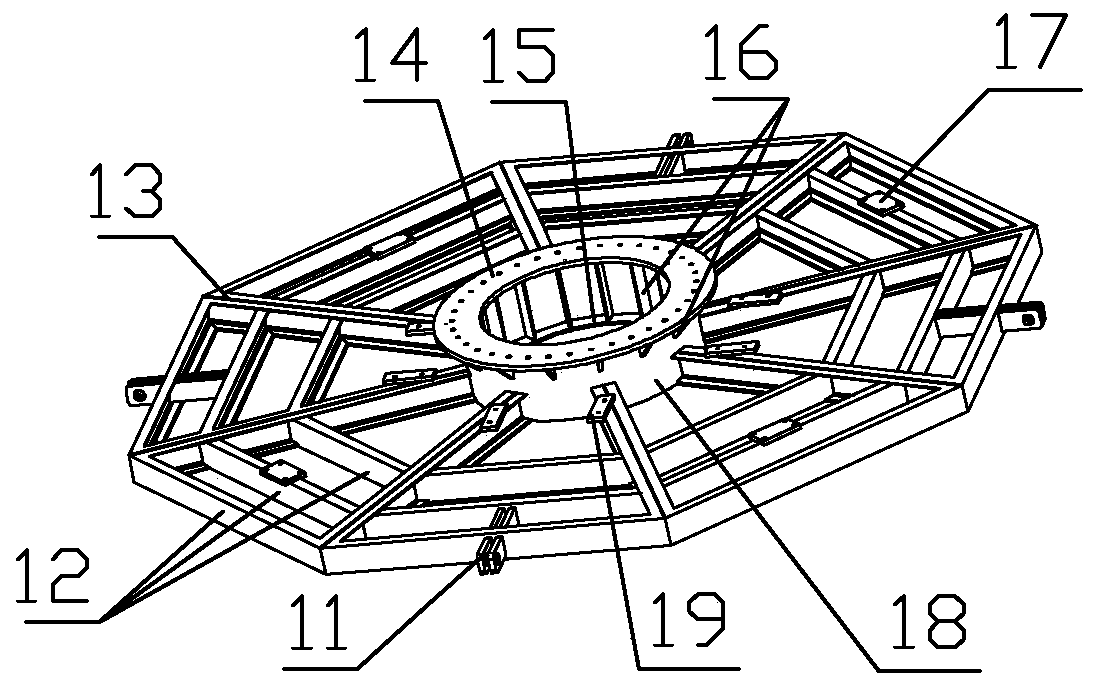

[0055] Such as Figure 1-1~Figure 1-2 As shown, the super-long main cable strand laying machine of the suspension bridge consists of a base 1, a slewing bearing 2, a rotating body 3, a connecting seat 4, a connecting rod 5, a cable tray 6, a damping brake 7 and an emergency braking brake 8. The fasteners are connected into one body;

[0056] The base 1 is fixed on the ground, the inner ring of the slewing bearing 2 is fixed on the base, the rotating body 3 is fixed on the outer ring of the slewing bearing 2, the connecting seat 4 is fixed on the rotating body 3, and the cable tray 6 is installed on the connecting seat 4, the connecting seat 4 and the cable tray 6 are connected and fixed through the connecting rod 5 and the pin shaft or bolts; the damping brake 7 and the emergency braking brake 8 are installed on the base 1.

[0057] Such as figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com