Tunnel waterproof and drainage construction technology

A construction technology, waterproof and drainage technology, applied in tunnels, drainage, tunnel lining and other directions, can solve problems such as increased safety hazards, increased tunnel fog, slippery ground, etc., to improve the anti-leakage performance and ensure the waterproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

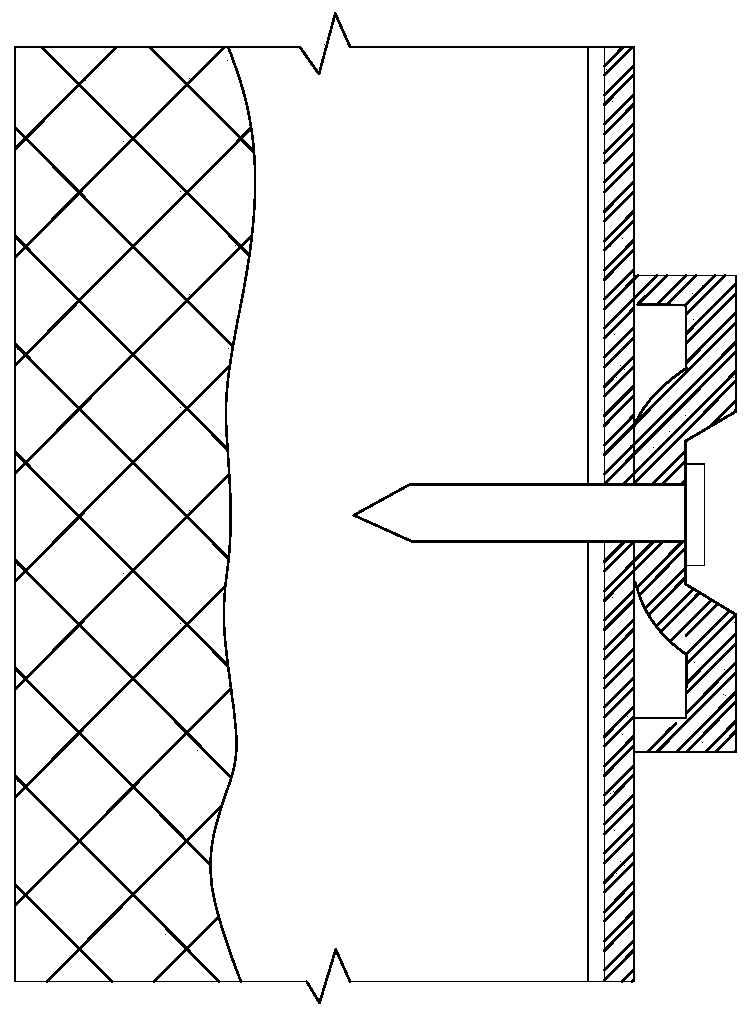

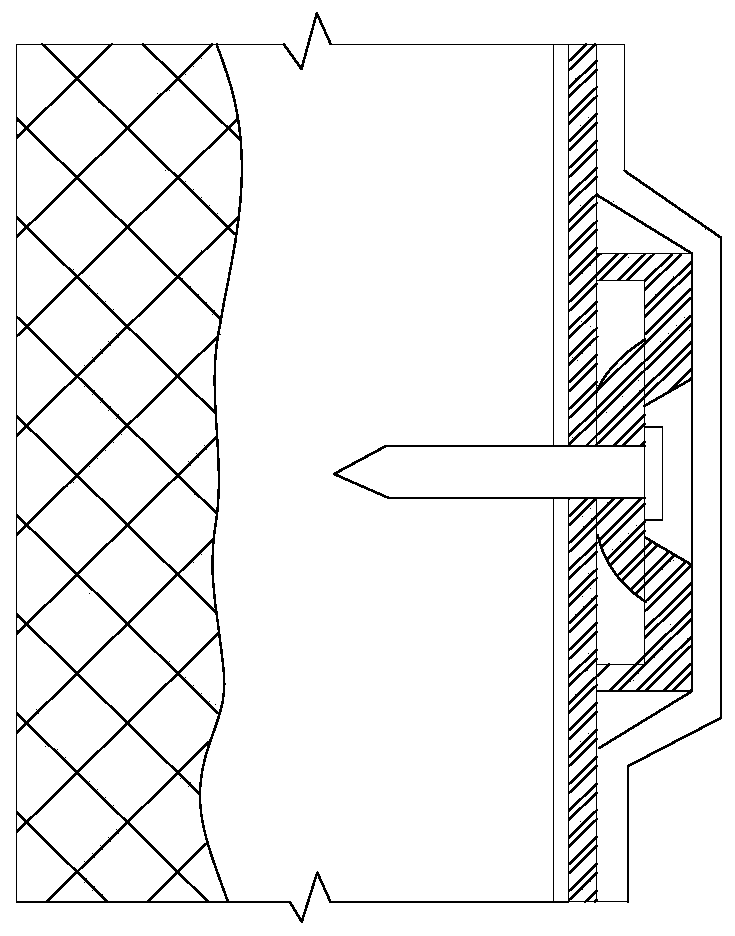

[0045] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0046] Such as Figure 1-11 As shown, a tunnel waterproofing and drainage construction process includes setting expansion water-stop strips on the entire section of the secondary lining construction joints of the tunnel, and setting rubber seals on the entire section of the settlement joints (set at the change of surrounding rock grade and at a distance of 50m in the V-level surrounding rock section). Water belts and back-mounted waterstops must be installed at construction joints and settlement joints. Longitudinal drainage pipes are arranged on both sides of the arch foot, circular blind pipes are arranged behind the secondary lining, geotextiles and waterproof boards are fully paved, and waterproof concrete with an impermeability level ≥ S8 is used for the secondary lining.

[0047] 1. Layout of tunnel drainage system

[0048] (1) The waterproof and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com