Universal joint nut and windproof supporting device for preventing clamping stagnation

A support device and universal joint technology, which is applied in the direction of transmission device, support machine, machine platform/support, etc., can solve the problems of easy damage of windproof support device, large moving distance, and failure to work normally, so as to eliminate howling sound, Solve the stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment this patent technology is further described.

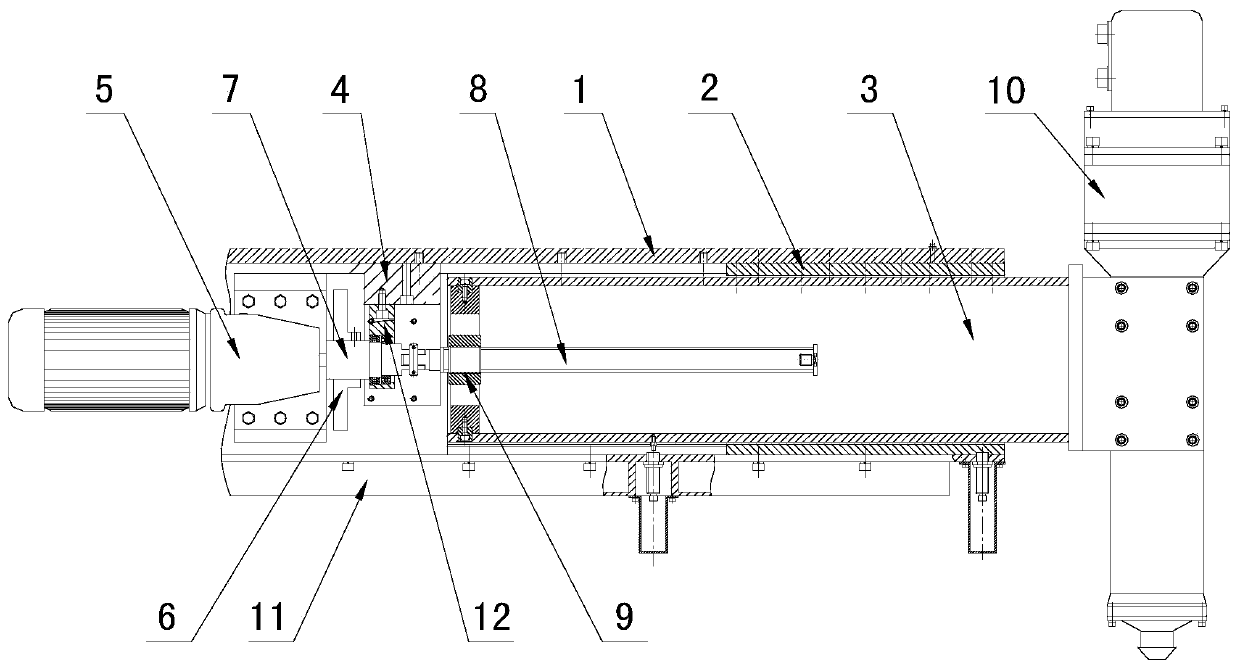

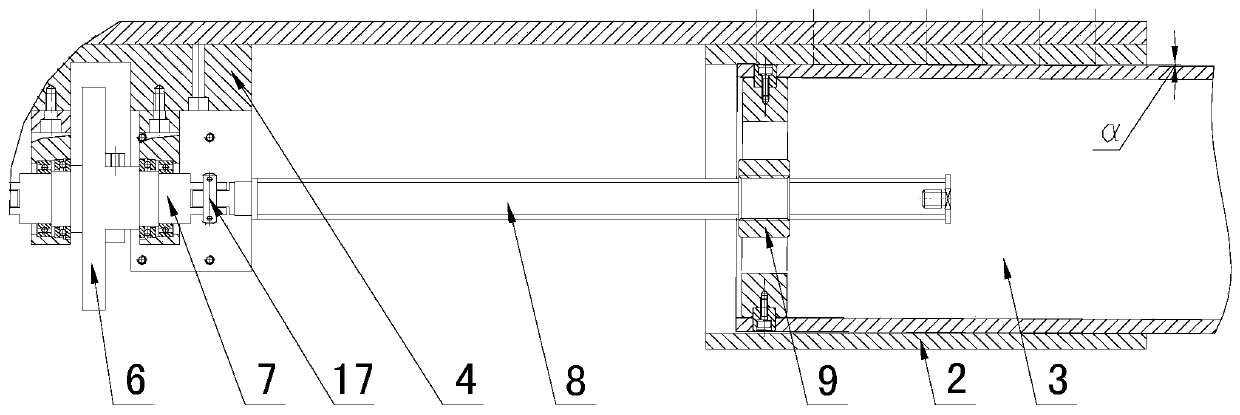

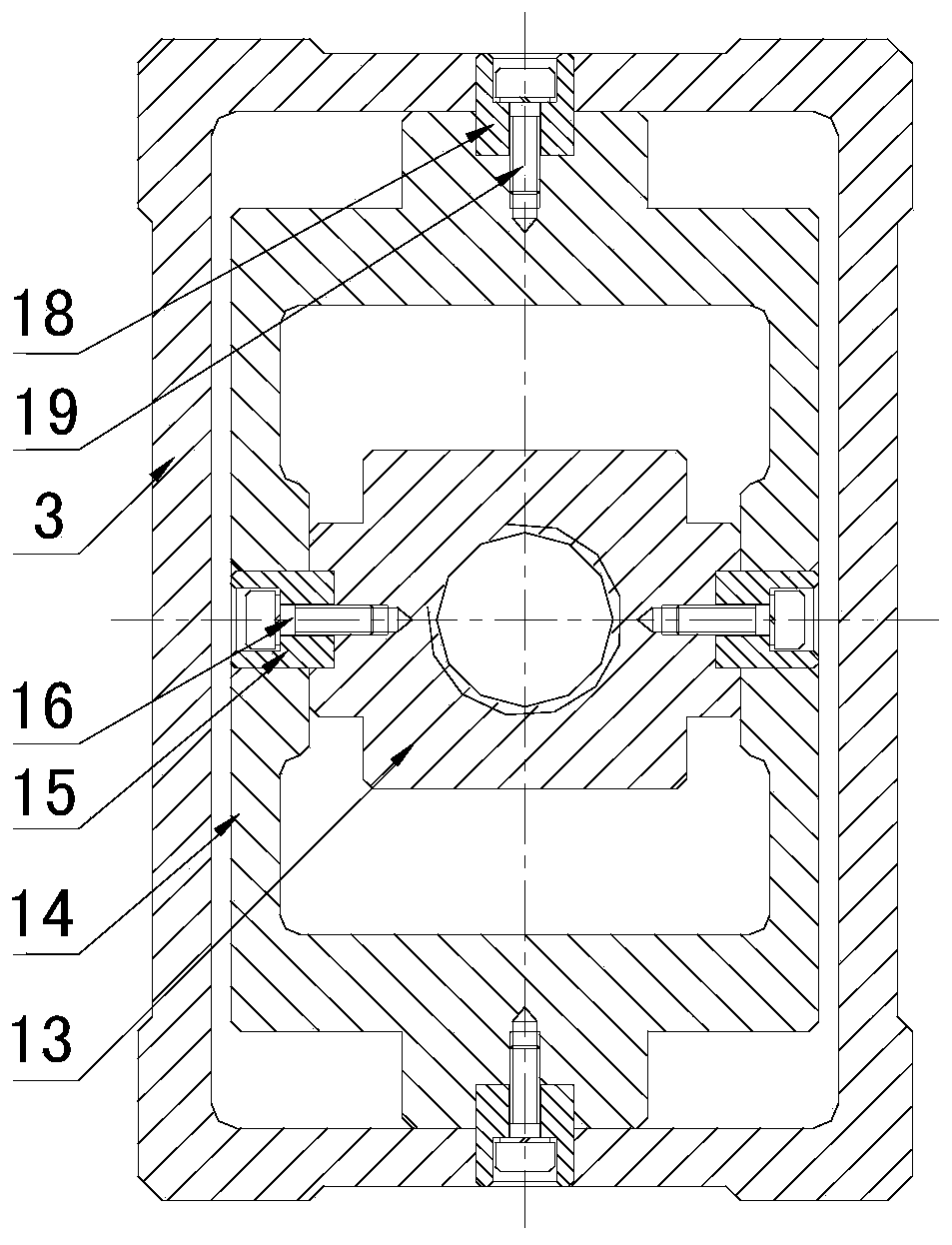

[0018] Such as figure 1 , figure 2 As shown, the anti-jamming windproof support device of the present invention includes a base plate 1, a base 4, a sliding seat 2, a reduction motor 5, a gear pair 6, a transmission shaft 7, a bearing seat 12, a universal joint nut 9, a lead screw 8, The supporting part 10 and the reinforcing structural part 11. The bottom plate 1 is fixed on the workbench 21 by bolts to strengthen the entire windproof support device so that its rigidity meets the wind resistance requirements, and is the installation base of the entire windproof support device. The base 4 is fixed on the base plate 1, the reduction motor 5, the gear pair 6, and the bearing block 12 are fixed on the base plate 1 through the base 4, and the transmission shaft 7 is installed on the bearing block 12. The output shaft of the reduction motor 5 is connected to the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com