a fiber optic cable

A fiber optic cable, a pair of technology, applied to the fiber optic cable. It can solve the problems of short time of anti-ant effect, and achieve the effect of good anti-ant effect and long duration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

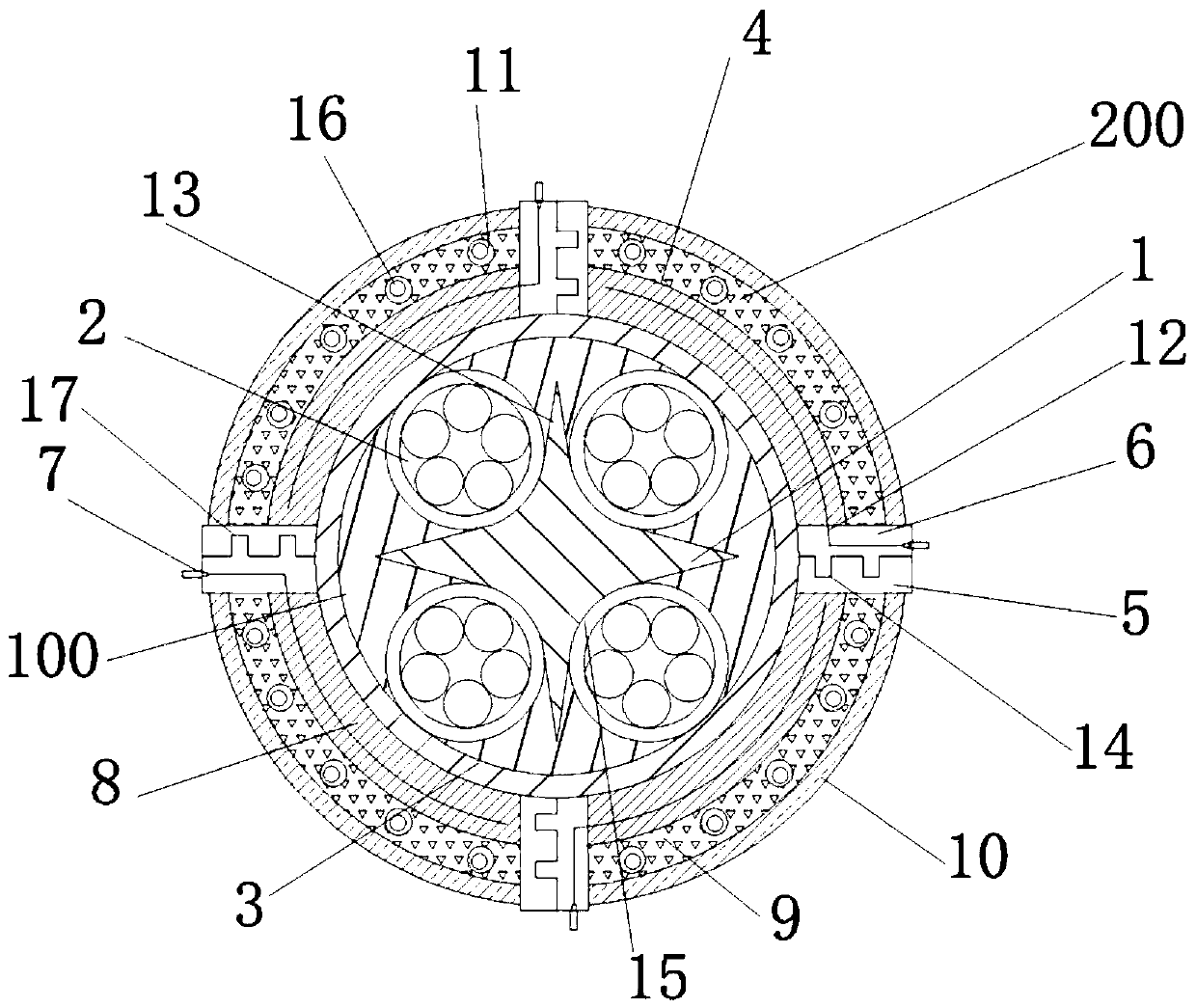

[0022] Such as figure 1 and figure 2 As shown, a kind of optical cable, comprises: optical cable core member 100 and detachable ant-proof assembly 200; Described optical cable core member comprises cross skeleton 1, is positioned at the optical fiber bundle 2 around cross skeleton and is positioned at the flame retardant layer 3 of outer skin; So Fiber paste is also filled between the cross frame and the flame-retardant layer.

[0023] The detachable anti-termite assembly includes four strip-shaped anti-ant units 4, and the two sides of the anti-ant units are respectively provided with a male plug 5 and a female plug 6 compatible with the male plug; the male plug is provided with At least one pair of connection heads 7; a waterproof hot-melt adhesive layer 8, a heat-resistant layer 9 and a nylon sleeve 10 are respectively provided between the male plug and the female plug from the inside to the outside. The male plug is provided with a pair of parallel strip-shaped sealing ...

Embodiment 2

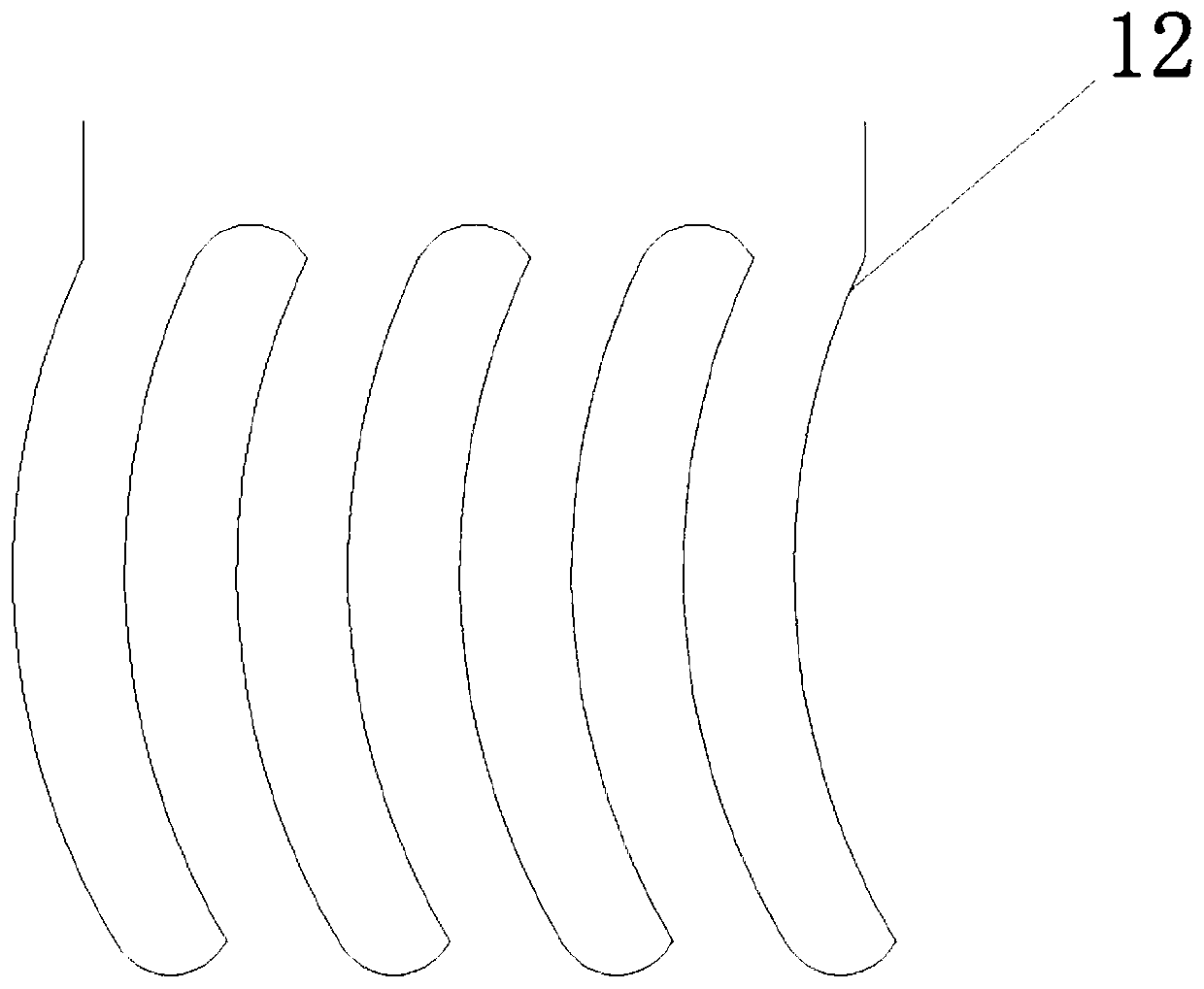

[0026] An optical cable, comprising: an optical cable core 100 and a detachable termite-proof assembly 200; the optical cable core includes a cross frame 1, an optical fiber bundle 2 positioned around the cross frame and a flame-retardant layer 3 positioned on an outer layer; the detachable The anti-ant component includes four strip-shaped anti-ant units 4, and the two sides of the anti-ant unit are respectively provided with a male plug 5 and a female plug 6 that is compatible with the male plug; the male plug is provided with at least one pair of terminals 7. The male plug and the female plug are respectively provided with a waterproof hot melt adhesive layer 8, a heat-resistant layer 9 and a nylon sleeve 10 from the inside to the outside; the anti-ant capsule 11 is fixed inside the heat-resistant layer, and the anti-ant An anti-ant solution is provided in the ant capsule; a heating wire 12 is provided in the waterproof hot melt adhesive layer, and two ends of the heating wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com