Internal circuit fixing structure for circuit breaker

A technology of internal circuit and fixed structure, which is applied in the direction of circuit breaker components, circuit breaker contacts, switch terminals/connections, etc., which can solve the problem of circuit breaker failure, two contacts cannot be contacted, and moving track deviation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

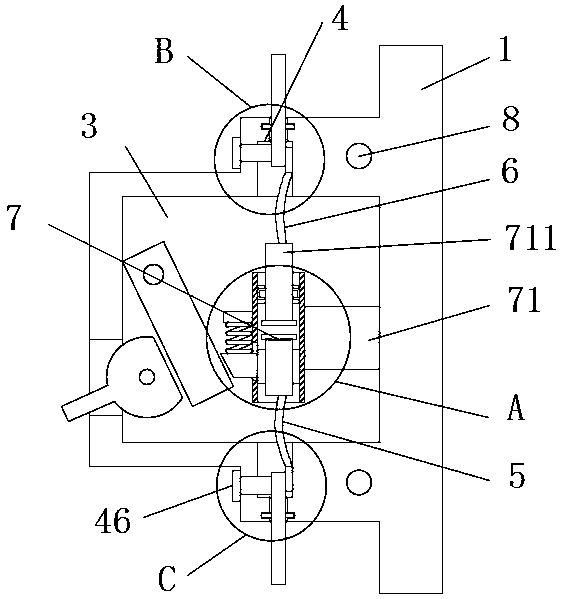

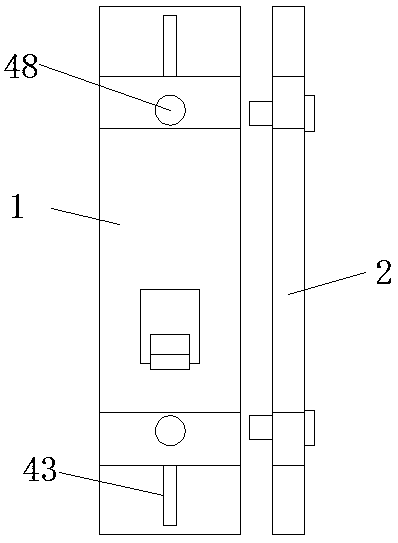

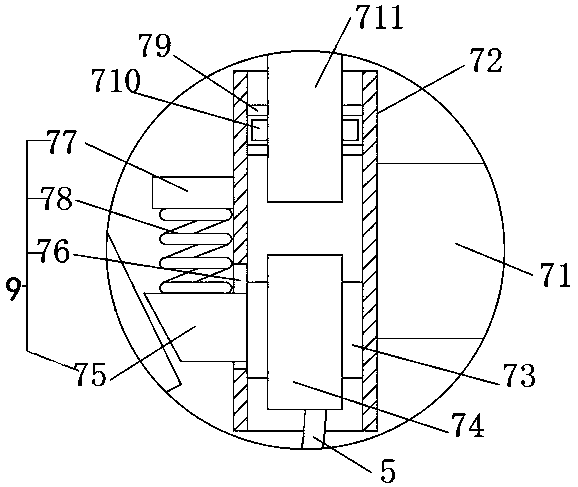

[0020] Such as Figure 1~5 As shown, a circuit breaker internal circuit fixing structure includes a housing 1, a circuit chamber 3 is opened inside the housing, two external circuit mechanisms 4 are symmetrically arranged on the upper and lower sides of the circuit chamber, and internal circuits are fixed in the circuit chamber. Mechanism 7, the internal circuit mechanism includes a fixed column 71, one end of which is fixed on the inner wall of the line cavity, and the other end is fixed on the outer wall of a vertically arranged connecting cylinder 72, the inside of the connecting cylinder is vertically hollow, and the connection A sliding sleeve 73 is slidably connected to the middle and lower sections in the barrel, and a first contact 74 is pierced inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com