Transparent substrate

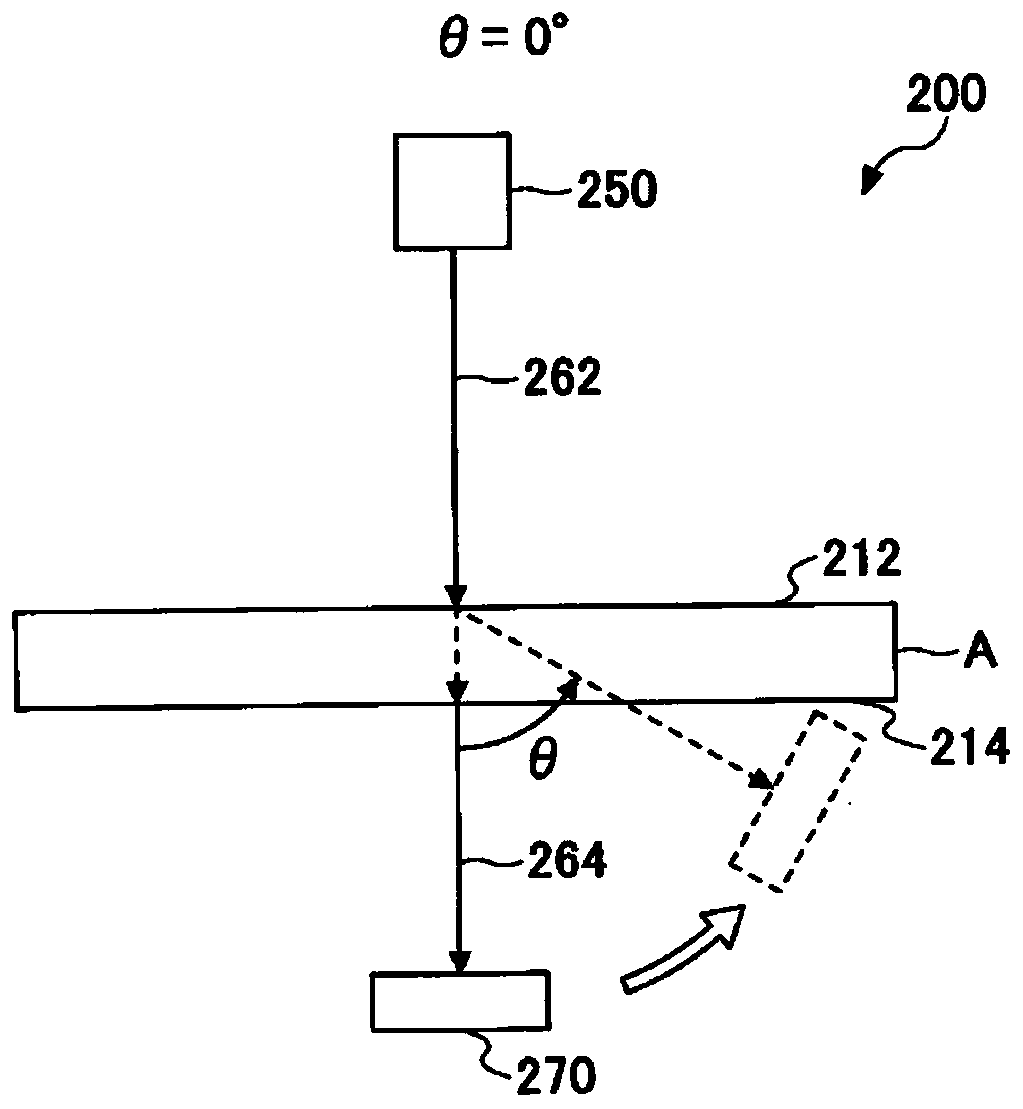

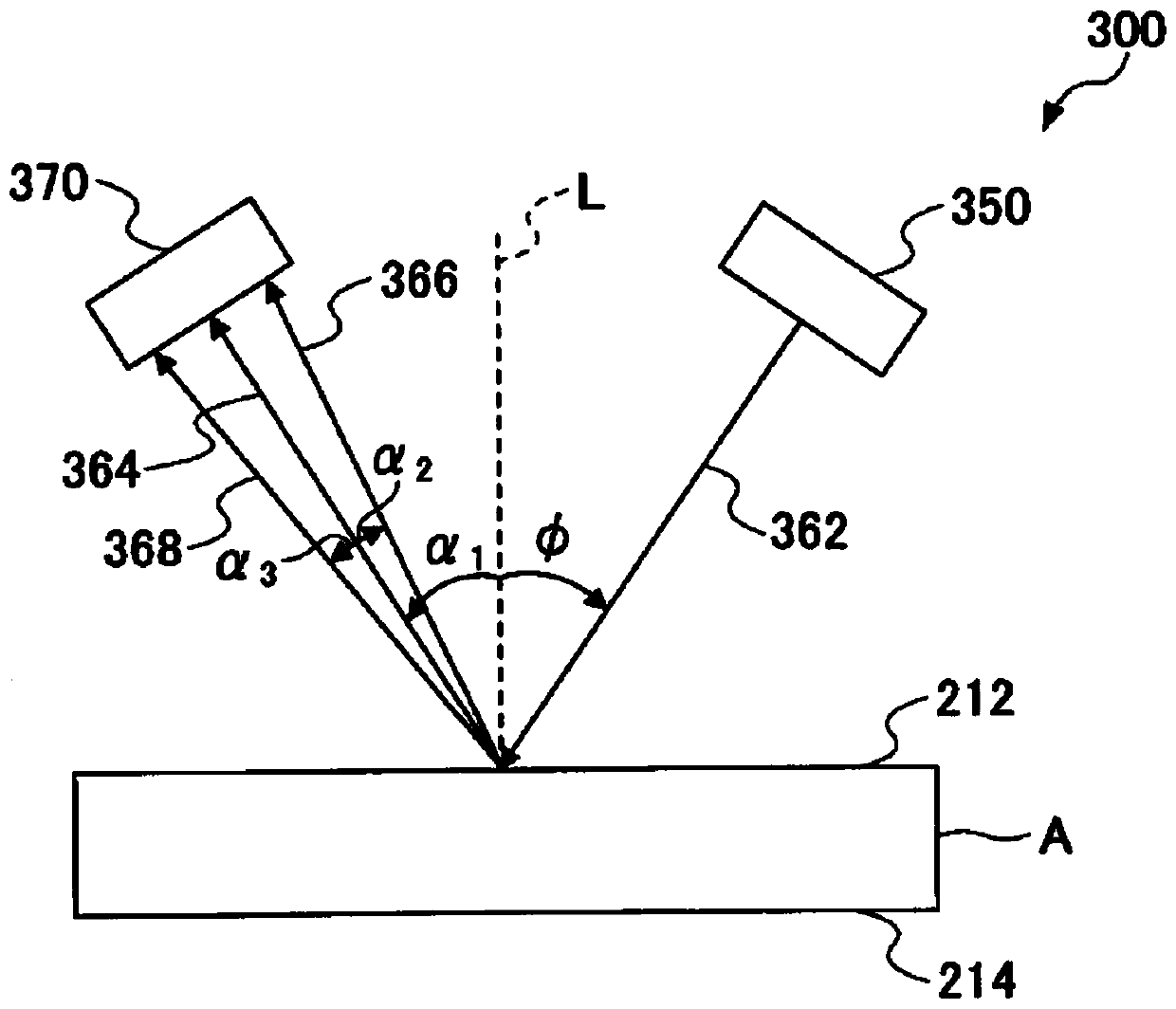

A technology of transparent substrate and transmitted light, applied in optics, instruments, optical components, etc., can solve problems such as difficult to observe images, unpleasantness, etc., and achieve the effect of suppressing glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0122] A transparent substrate with antiglare function was prepared by the following method.

[0123] First, a glass substrate with a thickness of 0.56 mm is prepared. The glass substrate is made of aluminosilicate glass and is not chemically strengthened.

[0124] Next, wet etching is performed on the glass substrate. Wet etching is performed by bringing an etchant into contact with only one surface (first surface) of the glass substrate. The etching solution is a mixed solution of hydrofluoric acid, sulfuric acid and ammonium fluoride. The etching depth was 5 μm (target value).

[0125] Thus, a transparent substrate having an antiglare function (hereinafter referred to as "sample 1") was obtained.

example 2

[0127] Using the following method, a transparent substrate with anti-glare function was prepared.

[0128] First, a glass substrate with a thickness of 0.71 mm is prepared. The glass substrate is made of aluminosilicate glass and is not chemically strengthened.

[0129] Next, sandblasting is given to one surface (1st surface) of this glass substrate. White alumina particles (#2000) were used as abrasive grains, and the pressure was 0.5 MPa.

[0130] Next, selective wet etching is performed on the first surface of the glass substrate. The etchant is a hydrofluoric acid solution. The etching depth was 32 μm (target value).

[0131] Thus, a transparent substrate having an antiglare function (hereinafter referred to as "sample 2") was obtained.

example 3

[0133] Using the same method as Example 2, a transparent substrate with anti-glare function was made. However, in Example 3, white alumina particles (#3000) were used as abrasive grains, and blasting was performed. In addition, the etching depth was 24 μm (target value). Other conditions are the same as in Example 2.

[0134] Thus, a transparent substrate having an antiglare function (hereinafter referred to as "sample 3") was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com