Draining mechanism and cooking utensil

A draining mechanism and draining technology, applied to the structure of cooking utensils, cooking utensils, utensils with integral electric heating devices, etc., can solve the problems of electrical safety hazards, etc., and achieve the advantages of reducing electrical safety hazards, simple structure, and stable rotation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the purpose, structure and function of the present invention, a draining mechanism and a cooking appliance of the present invention will be further described in detail below in conjunction with the accompanying drawings.

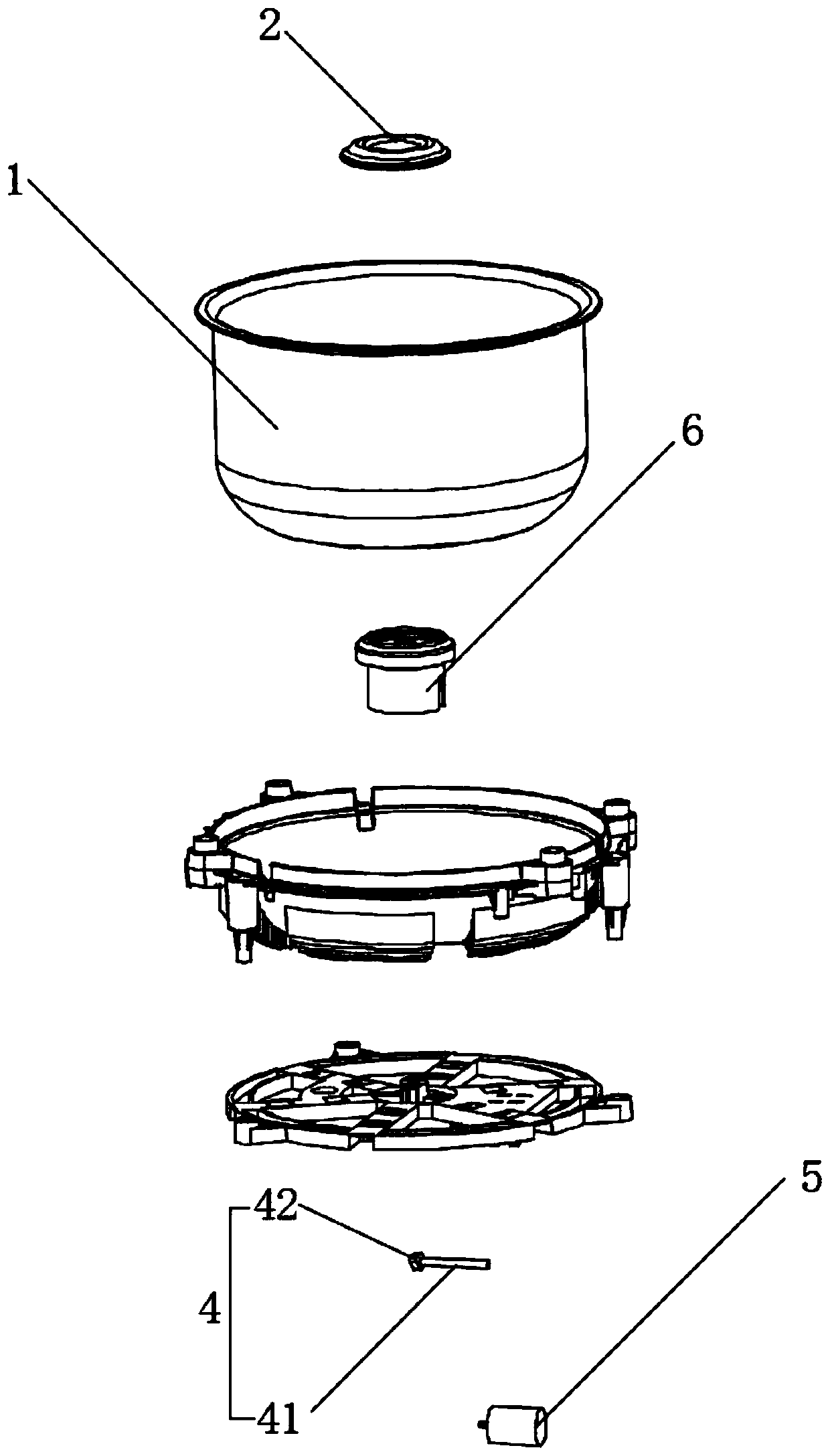

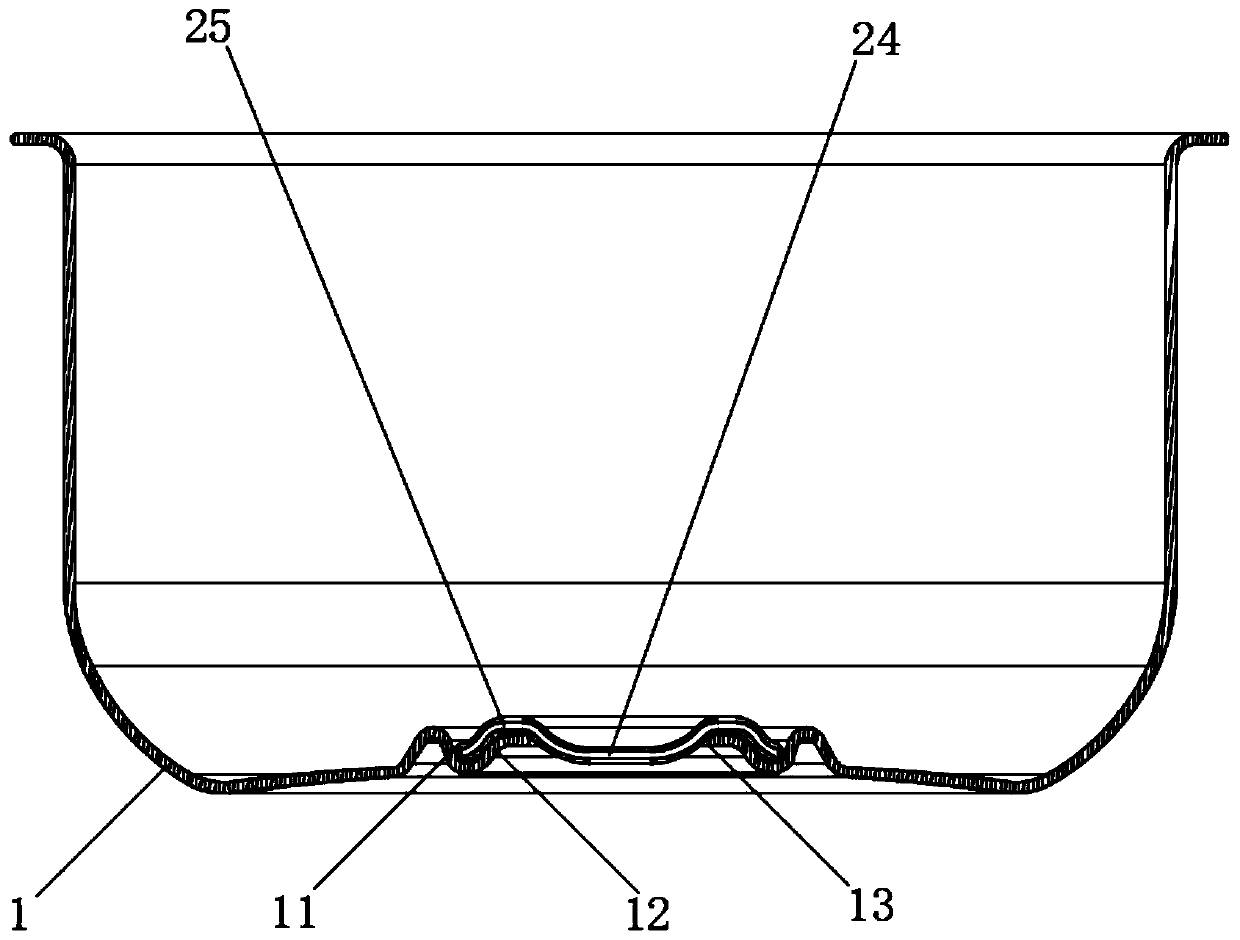

[0032] Such as figure 1 As shown, the cooking appliance of the present invention, taking an electric rice cooker as an example, includes a cooking body, an inner pot 1 and a draining mechanism. The draining mechanism controls the opening and closing of the draining port 12 at the bottom of the inner pot 1 to discharge excess rice soup from the draining channel. Thereby making sugar-free rice.

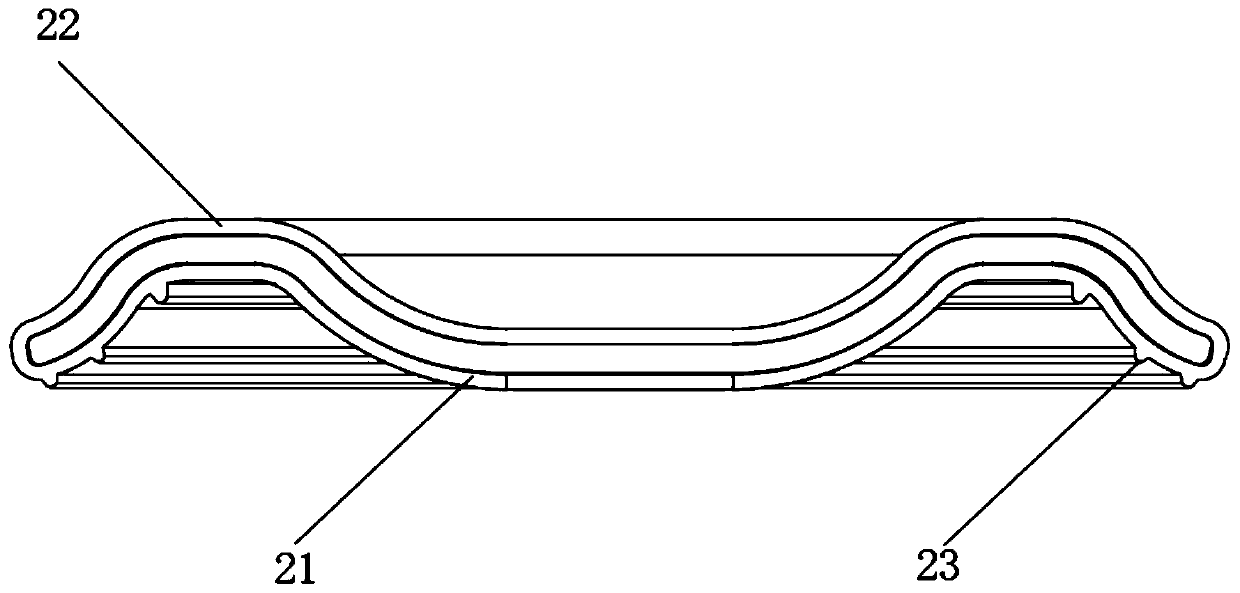

[0033] In order to control the opening and closing of the drain port 12, the drain mechanism includes a closing disc 2 and a driving mechanism. A positioning groove 11 is formed at the bottom of the inner pot 1, and the diameter of the positioning groove 11 gradually decreases from top to bottom, and a drain port 12 is provided at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com