Four-jaw chuck clamp used for high-precision four-jaw chuck

A four-jaw chuck, CNC machine tool technology, applied in the direction of the chuck, etc., can solve the problems of affecting the positioning accuracy, large wear, difficult to achieve accurate centering, etc., to achieve the effect of ensuring the centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

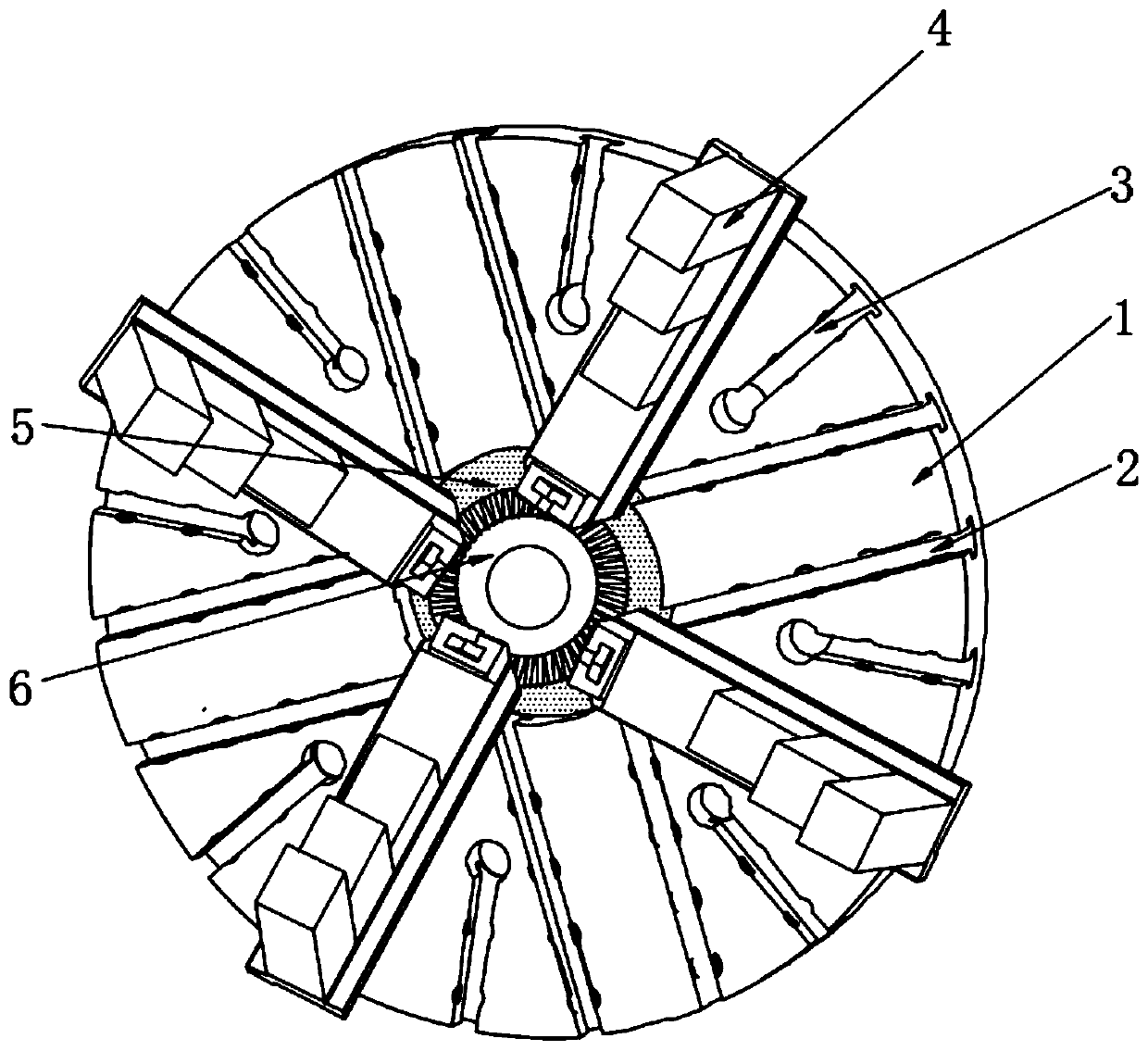

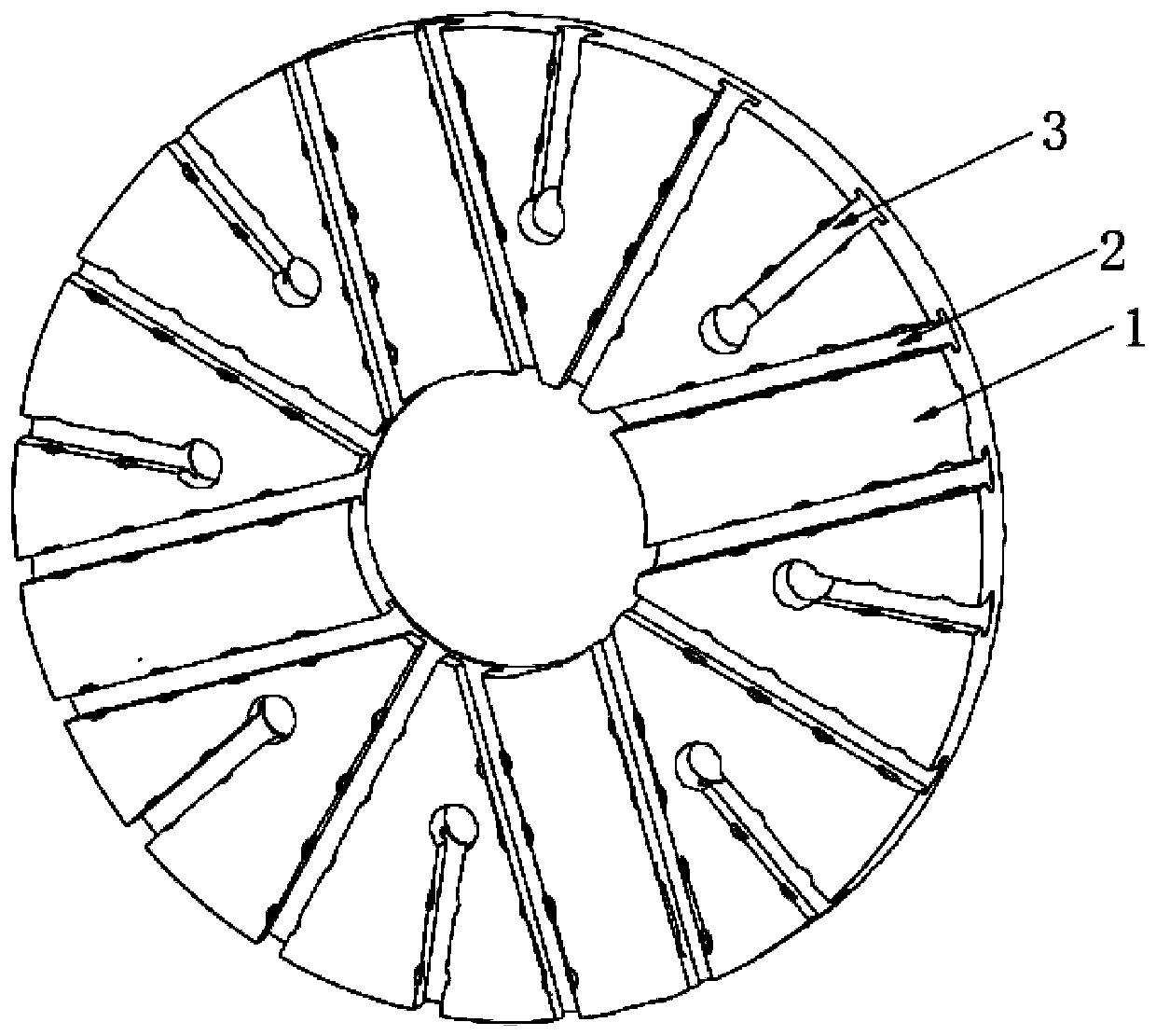

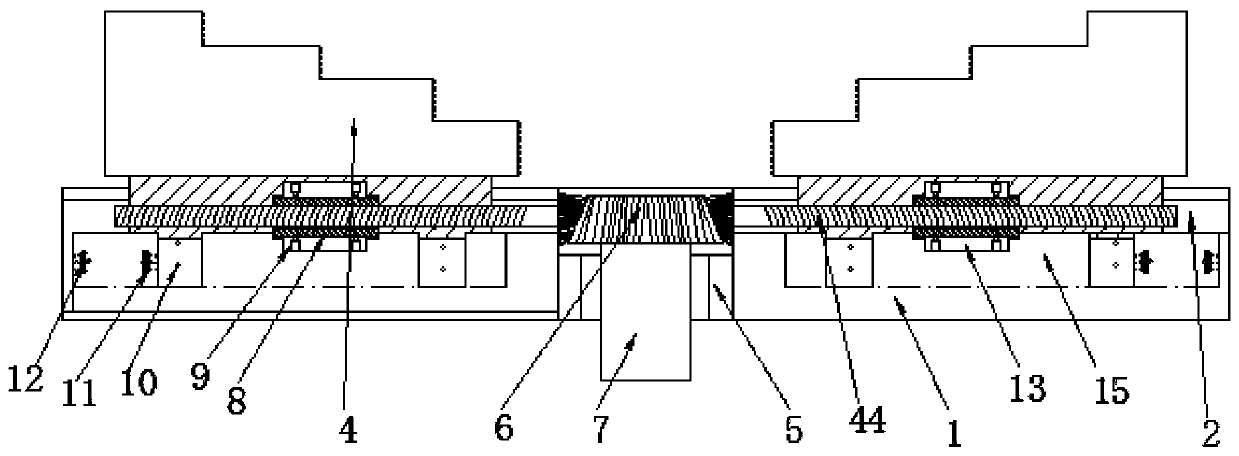

[0024] see Figure 1~6 , in an embodiment of the present invention, a four-jaw chuck fixture for a high-precision numerical control machine tool includes a four-jaw chuck 1, and multiple sets of T-shaped chute 2 are embedded in the front surface of the four-jaw chuck 1, The front side of the four-jaw chuck 1 is provided with four jaws 4 in a circular array through the T-shaped chute 2, and it is characterized in that a driving mandrel 7 is arranged at the center of the four-jaw chuck, and the driving The end of the mandrel 7 drives the jaws to move synchronously along the radial direction of the four-jaw chuck through a bevel gear transmission mechanism; A displacement detection mechanism for detecting displacement.

[0025] The present invention also includes a control and compensation mechanism, which can fine-tune and compensate the movement of the claws, so that when the displacement detection mechanism detects that the displacement of one or more claws is different from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com