Positioning structure and method for surface layer inserts

A positioning structure and positioning method technology, which is applied in the field of preparation of composite materials with surface inserts, can solve the problems of inability to achieve accurate positioning of inserts, inaccurate compensation effects, and increased weight of composite materials, achieving good promotion and application value and improving pass rate and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

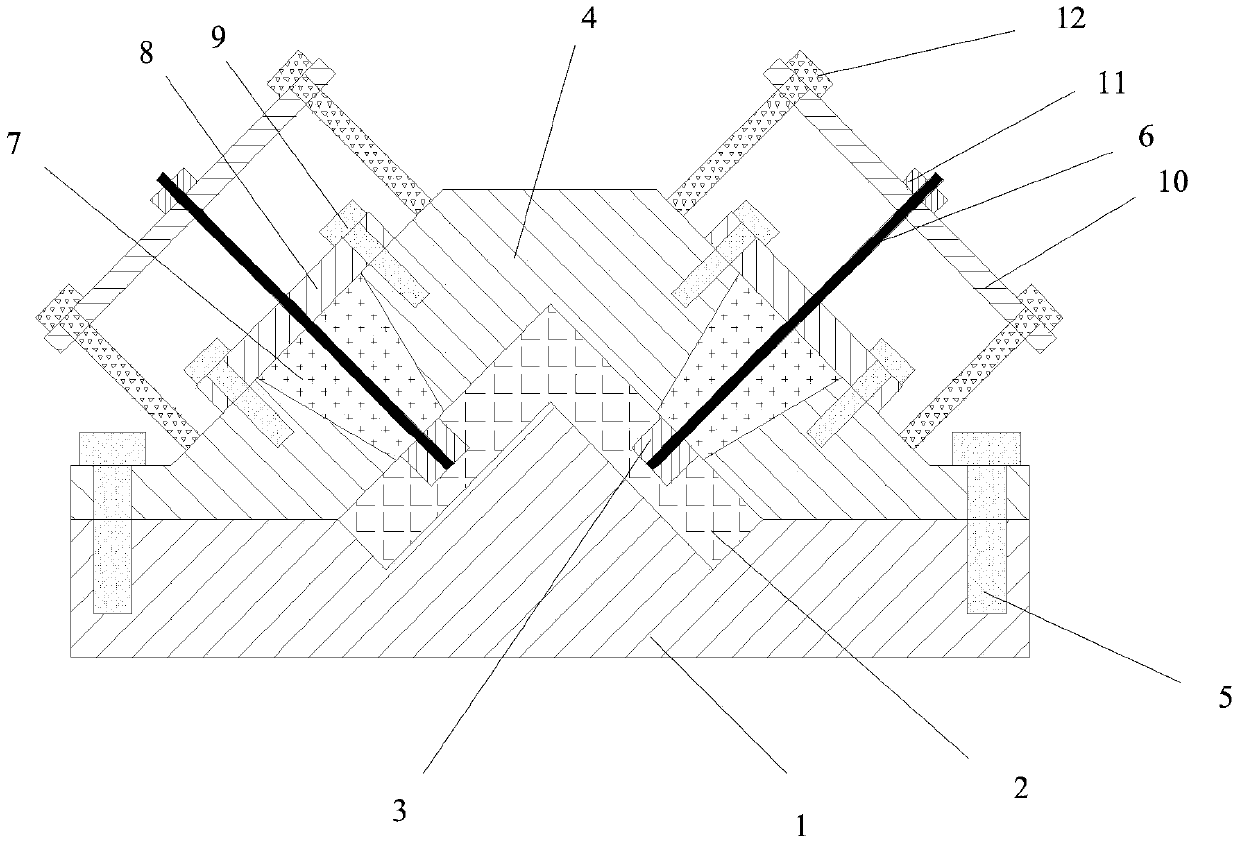

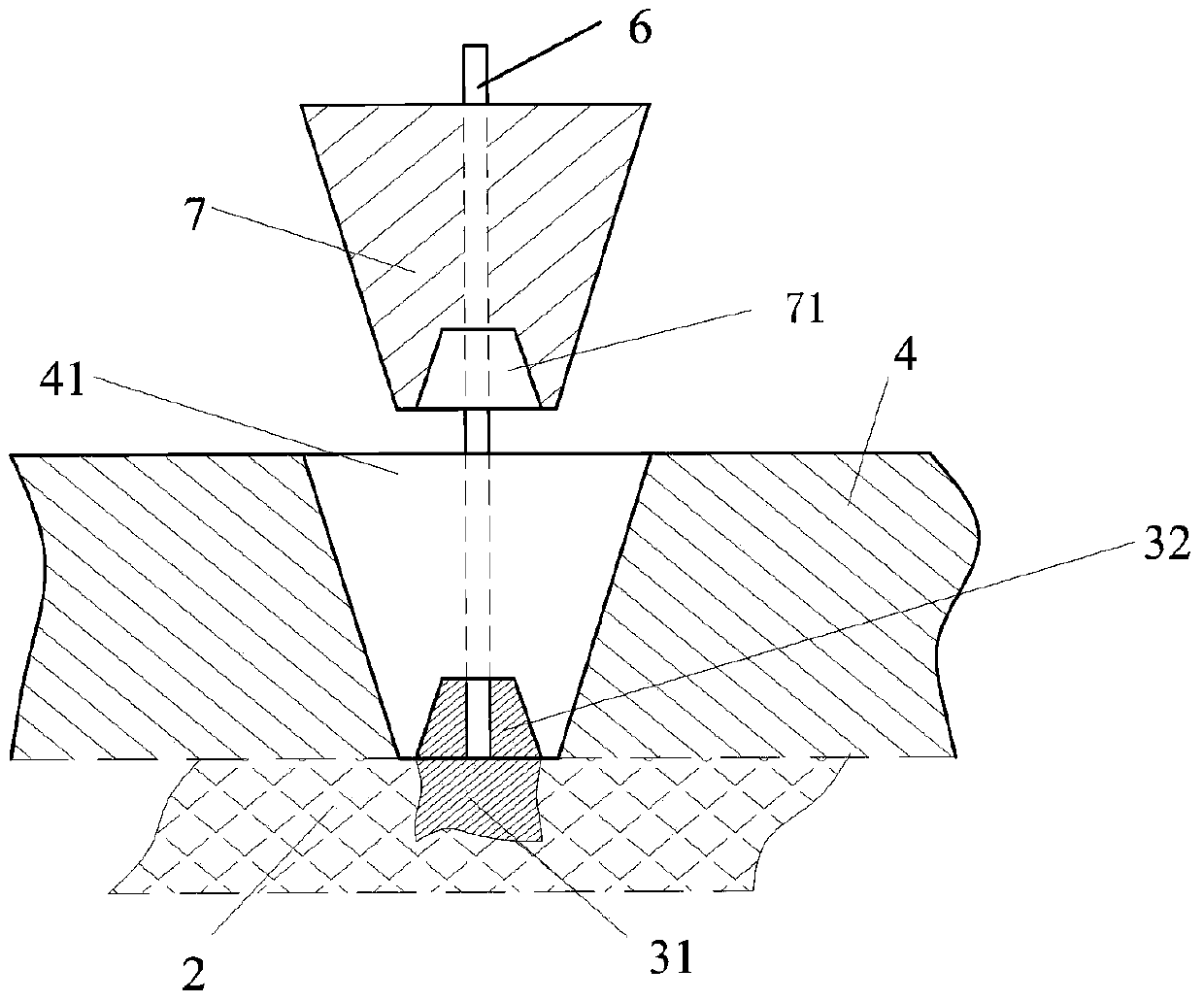

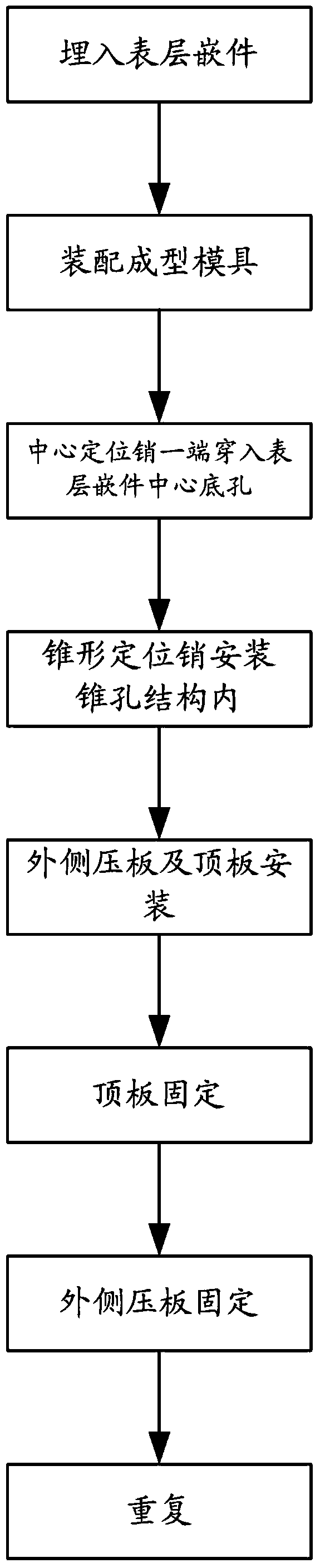

[0052] Carry out accurate positioning of 10 outer layer metal inserts 3 in an L-shaped cross-section composite quilted beam structure 2. The length of the L-shaped cross-section quilted beam structure is 1000 mm, and each side of the L-shaped cross-section has 5 metal inserts on the outer layer.

[0053] Manually lay carbon fiber plies layer by layer in the lower half-mold 1 of the forming mold to prepare an L-shaped cross-section quilted beam prefabricated body. The fiber plies whose outer layer needs to be embedded with metal inserts need to be pre-drilled according to the designed position (10 holes in total) ;

[0054] After the fiber layup is complete, metal inserts are placed in the openings of the layup;

[0055] Assemble the upper half-molds 1 and 4, align the upper and lower half-molds and insert the positioning pin 5, install the fastening bolts to ensure that the upper and lower half-molds are closed in place, and the gap between the joint surfaces is less than 0.05...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com