Turning conveyor for cargo transportation

A technology for cargo transportation and conveyors, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of damaged transported goods, easily wet transported goods, dirty outer packaging of transported goods, etc., to achieve Use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

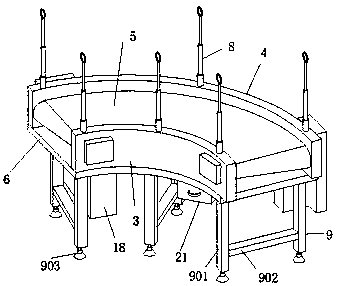

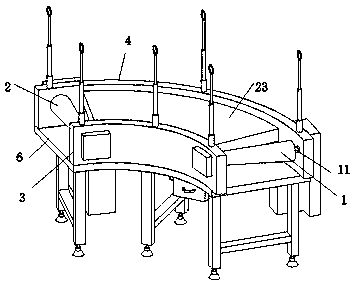

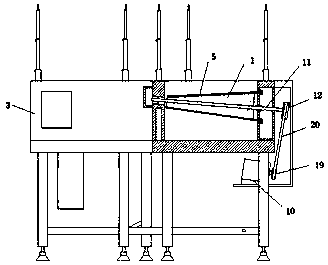

[0040] Such as Figure 1-5 As shown, the outer wall of the third rotating shaft 15 is also provided with a cleaning mechanism 7, and the cleaning mechanism 7 includes two semicircular sleeve pipes 701. 15 are fixedly connected by fixing screws, and the cleaning wire 702 is in contact with the lower surface of the turning belt 5, and then the third rotating shaft 15 rotates to clean dirt such as dirt and dust attached to the outer surface of the turning belt 5, which is beneficial Keep a good cleanliness when the turning belt 5 conveys goods.

Embodiment 2

[0042] Such as Figure 1-5 and Figure 10 As shown, the outer wall of the third rotating shaft 15 is also provided with a cleaning mechanism 7, and the cleaning mechanism 7 includes two semicircular sleeve pipes 701. 15 are fixedly connected by fixing screws, the cleaning mechanism 7 also includes a water nozzle 703, the water nozzle 703 is arranged on the left side of the third rotating shaft 15, and the direction of the water nozzle 703 is facing the cleaning wire 702; The outside of 703 is connected to the water storage tank 706 successively through the water delivery pipe 704 and the micro-water pump 705. The cleaning mechanism 7 also includes a water nozzle 703. The water nozzle 703 is arranged on the left side of the third rotating shaft 15, and the direction of the water nozzle 703 is positive. The cleaning wire 702; the outside of the water nozzle 703 is connected to the water storage tank 706 through the water delivery pipe 704 and the micro water pump 705 in sequenc...

Embodiment 3

[0044] Such as Figure 1-9 As shown, the inner track box 3 and the outer track box 4 are provided with a sunshade and rain-shielding mechanism 8, and the sunshade and rain-shielding mechanism 8 includes a first-level sleeve 801, a second-level sleeve 802, a third-level sleeve 803, and a sunshade hanging ring. 804 and sunshade 805, the third-level sleeve 803 is socketed on the inner wall of the second-level sleeve 802, the second-level sleeve 802 is socketed on the inner wall of the first-level sleeve 801, and the sunshade hanging ring 804 is fixed on the top of the third-level sleeve 803 The outer wall of the first-level sleeve 801 and the second-level sleeve 802 is provided with a clamping hole 806, and the outer wall of the second-level sleeve 802 and the third-level sleeve 803 is also provided with a circular groove 807, and the outlet of the circular groove 807 is fixed in a limited position. Ring 808, round groove 807 interior is fixed with back-moving spring 809, and bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com