Workpiece transfer system

A workpiece and transporter technology, which is applied in the direction of transportation and packaging, mechanical conveyors, conveyors, etc., can solve the problem of low efficiency of workpiece transfer, and achieve the effect of simple form, easy realization and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

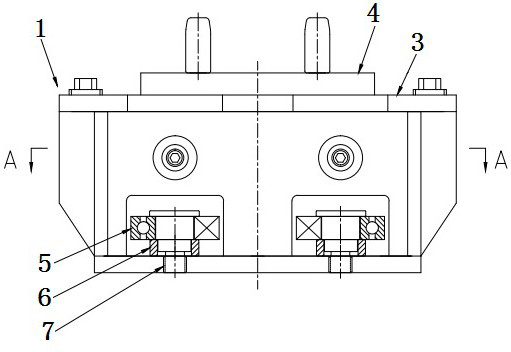

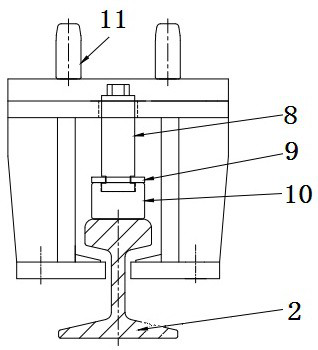

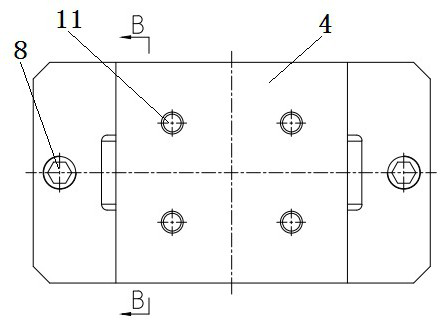

[0031] The specific implementation of the workpiece transfer system in the present invention will now be described in conjunction with the accompanying drawings.

[0032] like Figure 1 to Figure 5 As shown, the workpiece transfer system consists of two parts, which are the track 2 laid along the workpiece processing station in the designated working area and the supporting seat 1 used with the track 2. In this example, the track 2 is composed of two parts. The cross-section is formed by the parallel arrangement of I-shaped monorails. The bearing seat 1 is more flexible and light. When used in conjunction with the track 2, only one can be used, or two bearing seats 1 can be set on two parallel monorails for combination. Workpieces are transported.

[0033] The supporting base 1 includes a supporting base 3, and rollers for guiding and cooperating with the track 2 are respectively arranged on the supporting base 3, and the rollers include a driving wheel 14 which drives the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com