Bulk distributing system of storage yard

A distribution system and yard technology, applied in the field of bulk material distribution system in the yard, can solve the problems of heavy workload, low utilization rate of the yard, and inability to meet the stockpiling in the yard area, so as to improve the utilization rate, the degree of automation and the High reliability and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

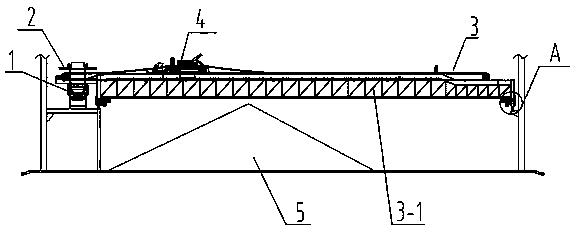

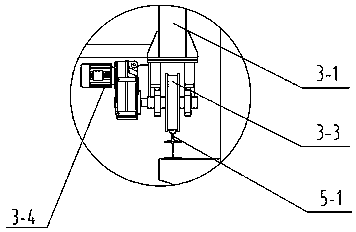

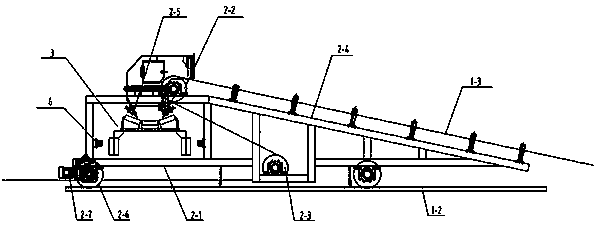

[0025] Such as Figure 1~6 As shown, the present invention provides a bulk material distribution system in a stockyard, including a main conveyor 1, an unloading vehicle 2, a driving belt conveyor 3, a mobile unloader 4 and an electric control system. The field 5 is vertically arranged, and the driving belt conveyor 3 is arranged horizontally along the storage yard 5, and bulk materials are sent to the storage yard 5 through the main conveyor 1, the unloading vehicle 2, the driving belt conveyor 3 and the mobile unloader 4 in sequence, and the described The truss 1-1 of the main conveyor 1 is provided with a first track 1-2, the unloading vehicle 2 walks on the first track 1-2, and the two sides of the storage yard 5 are provided with belt conveyors 3 for driving. The second track 5-1, the truss 3-1 of the driving belt conveyor 3 is provided with a third track 3-2, the mobile unloader 4 walks on the third track 3-2, the main conveyor The driving devices of the machine 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com