Drilling and perforating mechanism

A driving mechanism and drilling rod technology, applied in drilling equipment and methods, drilling equipment, directional drilling, etc., can solve the problem of low adjustability of drilling and drilling mechanisms, poor ability to adapt to different working conditions, and adjustment of drilling azimuth Inconvenience and other problems, to achieve the effect of good comprehensive use performance, improved adaptability, and good adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

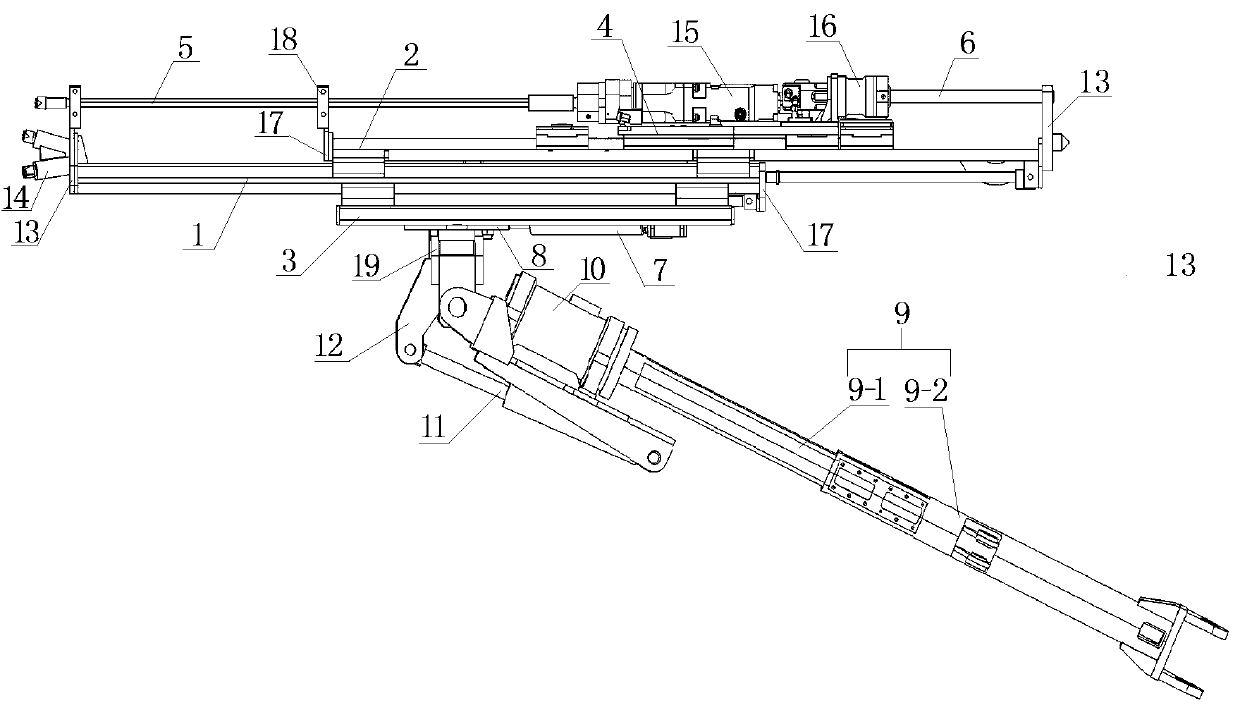

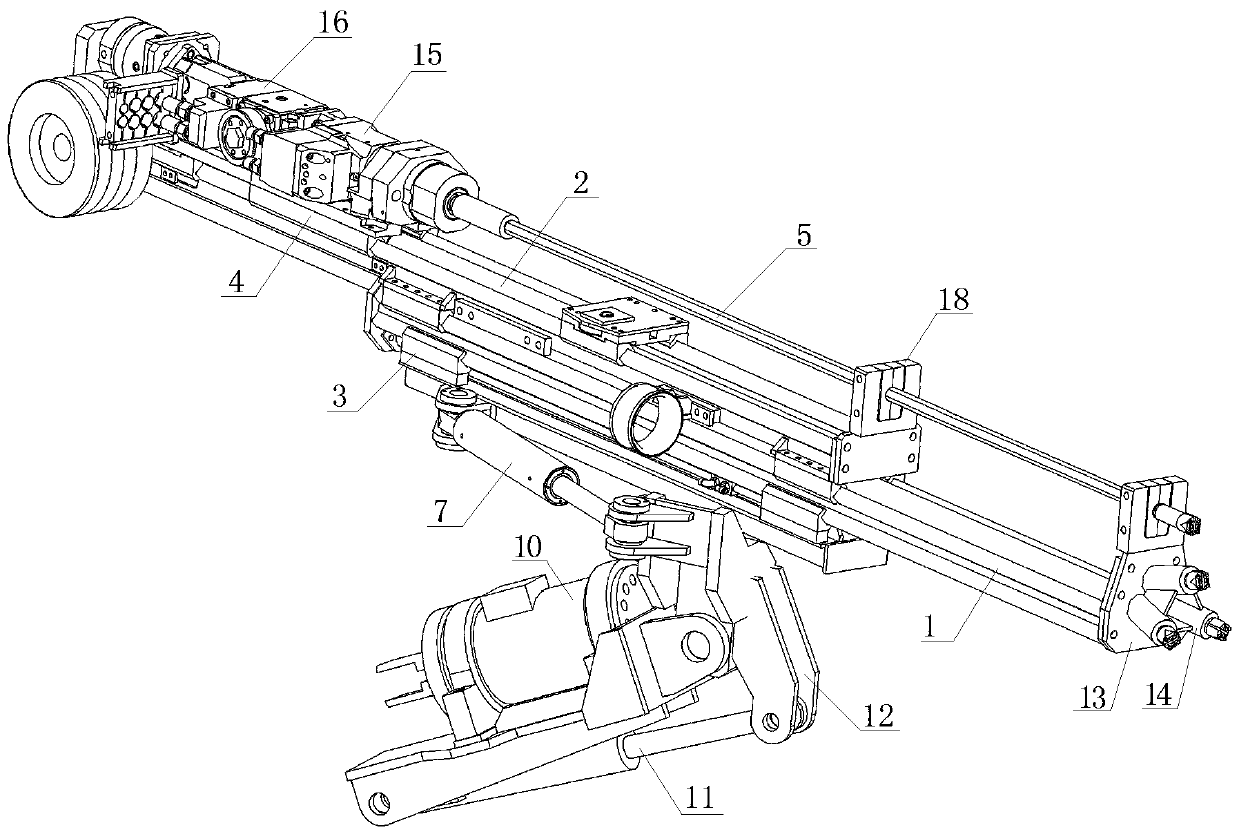

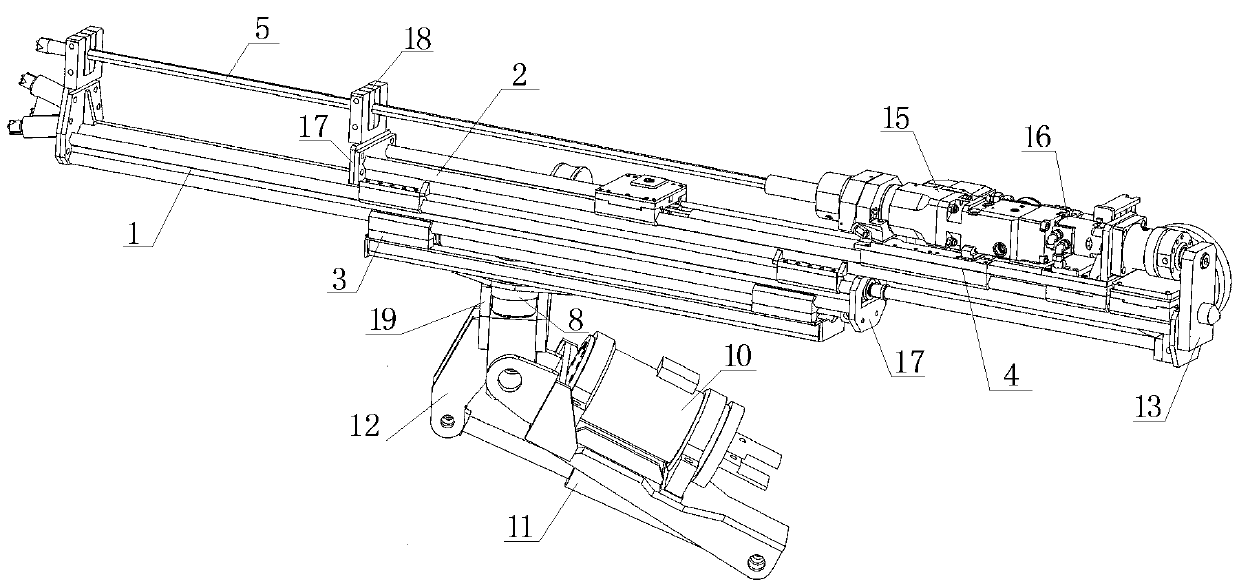

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0027] The invention discloses a long drilling and punching mechanism, which can be used for drilling rods in coal mine roadways and tunnels in cooperation with equipment such as roadheaders. The following are specific examples:

[0028] The invention relates to a drilling and punching mechanism, which realizes three-stage expansion and contraction by setting three slideways that can move relative to each other and two drill rods. On the premise that the required installation space remains unchanged, it is equivalent to lengthening the length of the slideway, thereby increasing the stroke of the drill pipe. Further, two drill rods can also be set on the drilling and punching mechanism, and different drill bits can be installed on the two drill rods to perform different types of drilling operations.

[0029] In order to achieve three-stage tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com