A method of exempting from factory calibration of gas detectors

A gas detector and calibration-free technology, which is applied in the direction of standard gas analyzers, gas mixture analysis, instruments, etc., to improve production efficiency and avoid complicated and cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

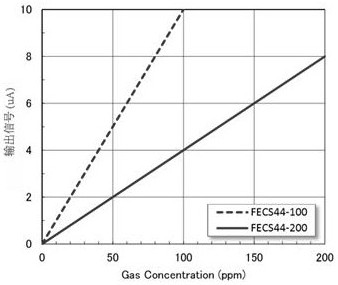

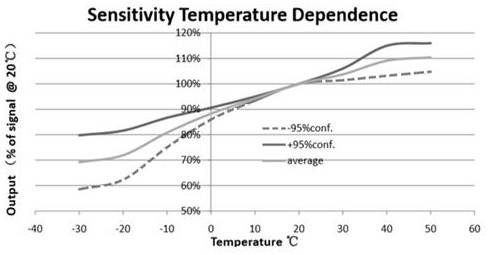

[0020] A gas detector includes a sensor. Taking one of the gas sensors as an example, the characteristic curve 1 (output signal-temperature curve) of the sensor is as attached figure 2 As shown, describe the method of ex-factory calibration for gas detectors.

[0021] Include the following steps in turn:

[0022] S100, place the assembled gas detector in clean air for 1 minute, take multiple samples, and determine the zero-point AD sampling value, so as to exclude the difference between individual detector devices.

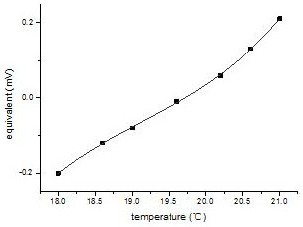

[0023] S200, setting the built-in characteristic curve of the sensor in the gas detector as a cubic polynomial y=a 0 +a 1 t+a 2 t 2 +a 3 t 3 , on the built-in characteristic curve of the sensor, 7 sets of discrete data are arbitrarily selected near the temperature of 20°C, as shown in Table 1; the cubic polynomial is fitted by the software using the least square method, and the coefficient a is obtained 0 、a 1 、a 2 、a 3 The specific value of , as shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com