Oil nozzle matching part flow testing device and method

A flow test device and a technology of even parts, which are applied in the direction of measuring device, machine/structural component test, fuel injection device, etc., can solve the problem of inability to complete the flow test of the nozzle without ring groove or step surface at the end of the needle valve, and manually adjust the accuracy Unable to guarantee, complex and cumbersome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

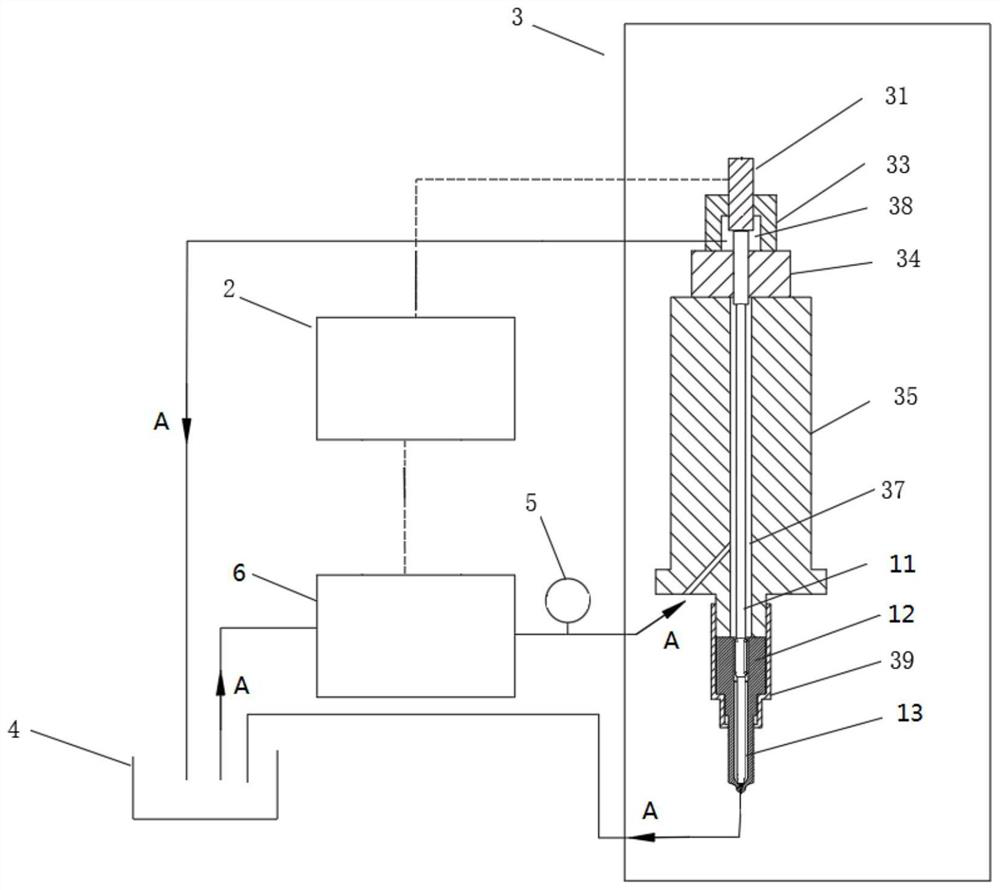

[0050] This embodiment proposes a flow test device for the nozzle assembly, which can test the flow rate of the long needle valve assembly at different lifts or at the same lift. It has good versatility, good control accuracy, and high work efficiency. High and easy to operate. The device for testing the flow rate of the nozzle assembly in this embodiment is suitable for flow testing of various nozzle assemblies similar in structure to the long needle valve assembly.

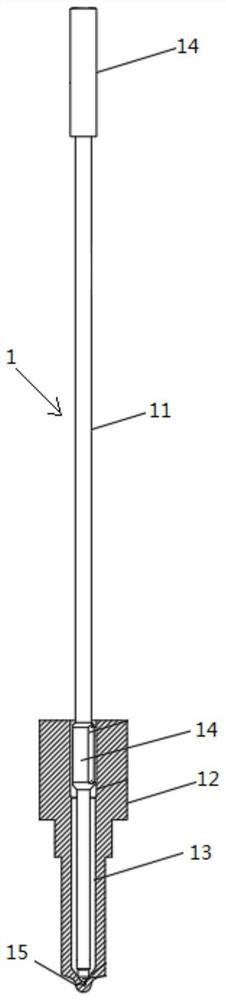

[0051] Among them, such as figure 1 As shown, the long needle valve nozzle assembly 1 includes a needle valve body 12 and a needle valve 11 inserted on the needle valve body 12, and an outer cylinder 14 is arranged at the head and tail of the needle valve 11, and the head of the needle valve 11 The outer cylinder 14 of the upper part is located in the needle valve body 12 and is in clearance fit with the needle valve body 12, and a pressure accumulator chamber 13 is formed between the needle valve 11 and the ne...

Embodiment 2

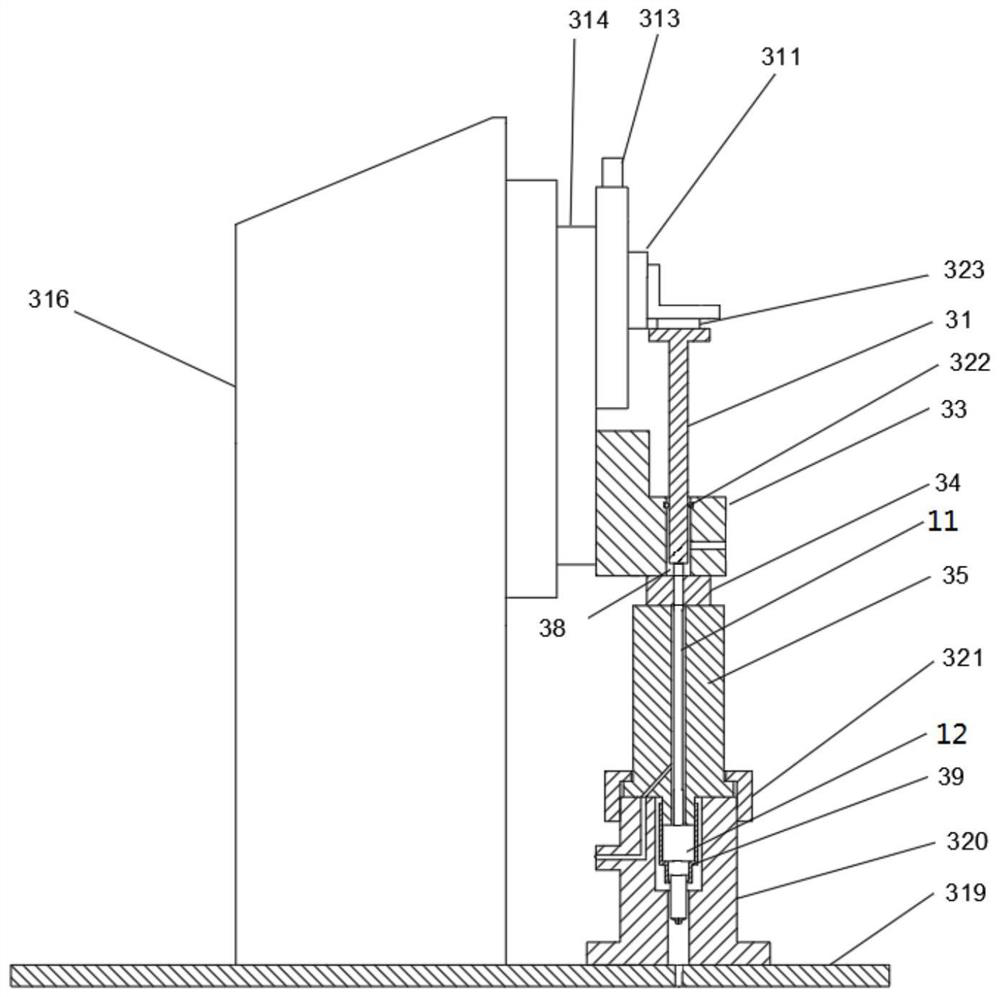

[0066] In this embodiment, a flow test device for the nozzle coupler is proposed, such as Figure 4 As shown, the difference between the nozzle assembly flow test device in this embodiment and the first embodiment is that the control method for the height of the needle valve 11 in the vertical direction is different, that is, the nozzle assembly in this embodiment The flow test device does not include the driving member 313 , the pressure sensor 323 and the needle valve plunger 31 .

[0067] Specifically, such as Figure 4 As shown, by increasing the height of the sealing slide 34 or the length of the clamp body 35, the tail of the needle valve 11 is lower than the top surface of the sealing slide 34, and at the same time, an oil return channel communicating with the oil tank 4 is provided on the test pressure head 33, Therefore, the tail of the needle valve 11 does not bear the force of the oil pressure, and the relative height of the tail of the needle valve 11 lower than t...

Embodiment 3

[0069] In this embodiment, a test method based on the flow test device of the nozzle assembly as in the first embodiment is proposed, including the following steps:

[0070] S1: the control system 2 controls the operation of the driving member 313, so that the driving member 313 drives the needle valve ejector rod 31 to move vertically downward, so that the needle valve ejector rod 31 presses against the tail of the needle valve 11;

[0071] S2: The control system 2 controls the oil supply assembly 6 to supply test oil with pressure value and temperature value into the pressure chamber 37, and the test oil in the pressure chamber 37 can pass through the gap between the outer cylinder 14 at the head of the needle valve 11 and the needle valve body 12. The gap between them flows into the accumulator chamber 13, and a tapered seal is formed between the head of the needle valve 11 and the bottom end of the needle valve body 12, so that the head of the needle valve 11 can bear the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com