A Method for Evaluating Caprock Effectiveness

An effective and caprock technology, applied in the field of oil and gas exploration, can solve problems such as the inability to achieve effective evaluation of caprocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Taking the Shizhu syncline in Western Hubei-Eastern Chongqing as an example

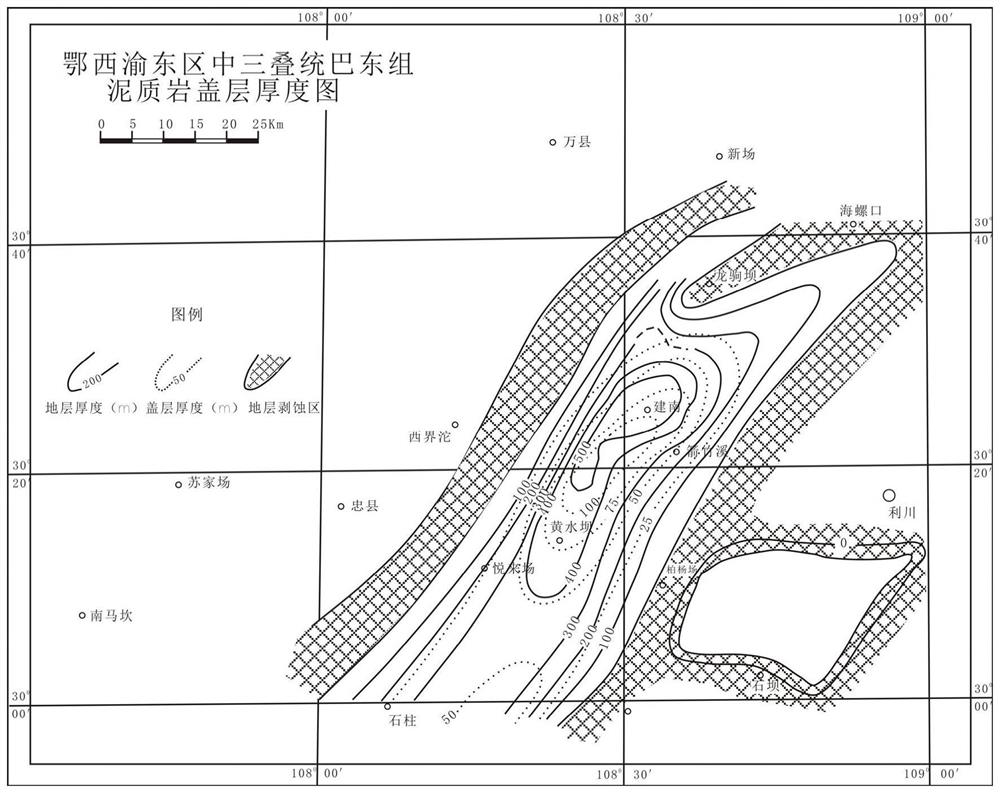

[0049] (1) Determine the structural characteristics of the study area and the thickness distribution of the main cap rocks (see figure 1 ). According to the statistics of oil and gas wells and failed wells, the formation thickness in the effective caprock development area is at least 300m. In most areas of the Shizhu syncline in the Western Hubei-Eastern Yu region, the thickness of the shale formation is greater than 300m, and the macroscopic conditions of the caprock are good.

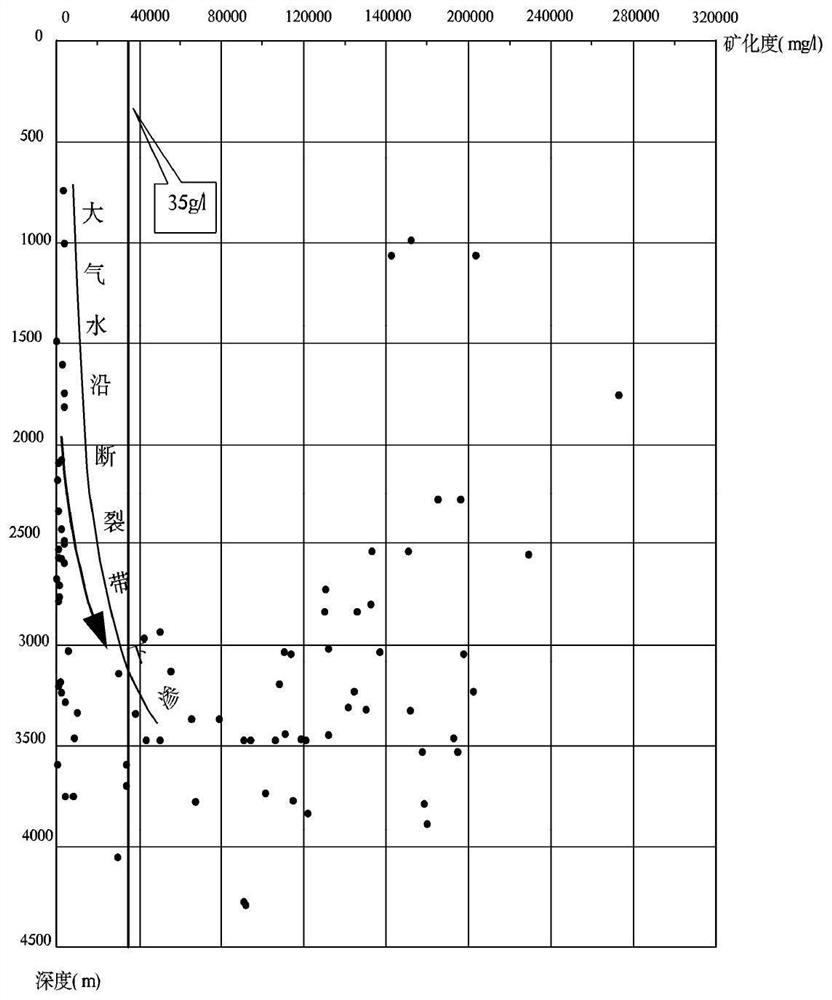

[0050] (2) According to the water chemical zoning, the minimum buried depth is determined to be 500m (see figure 2 ). Excluding the impact of structural surface water and groundwater in the fault zone, statistics show that the water chemical alternation block zone is below 500m, indicating that the preservation conditions are good.

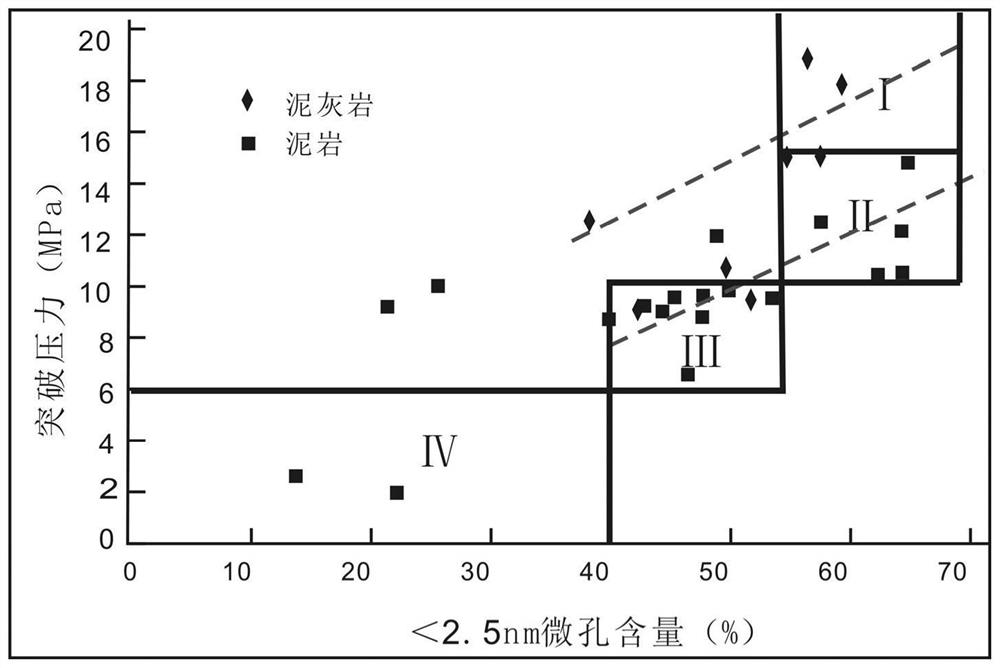

[0051] (3) According to the breakthrough pressure and ultramicropore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com