Floor drain position adjusting mechanism and floor drain

A technology for adjusting mechanisms and floor drains, applied in water supply devices, drainage structures, waterway systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

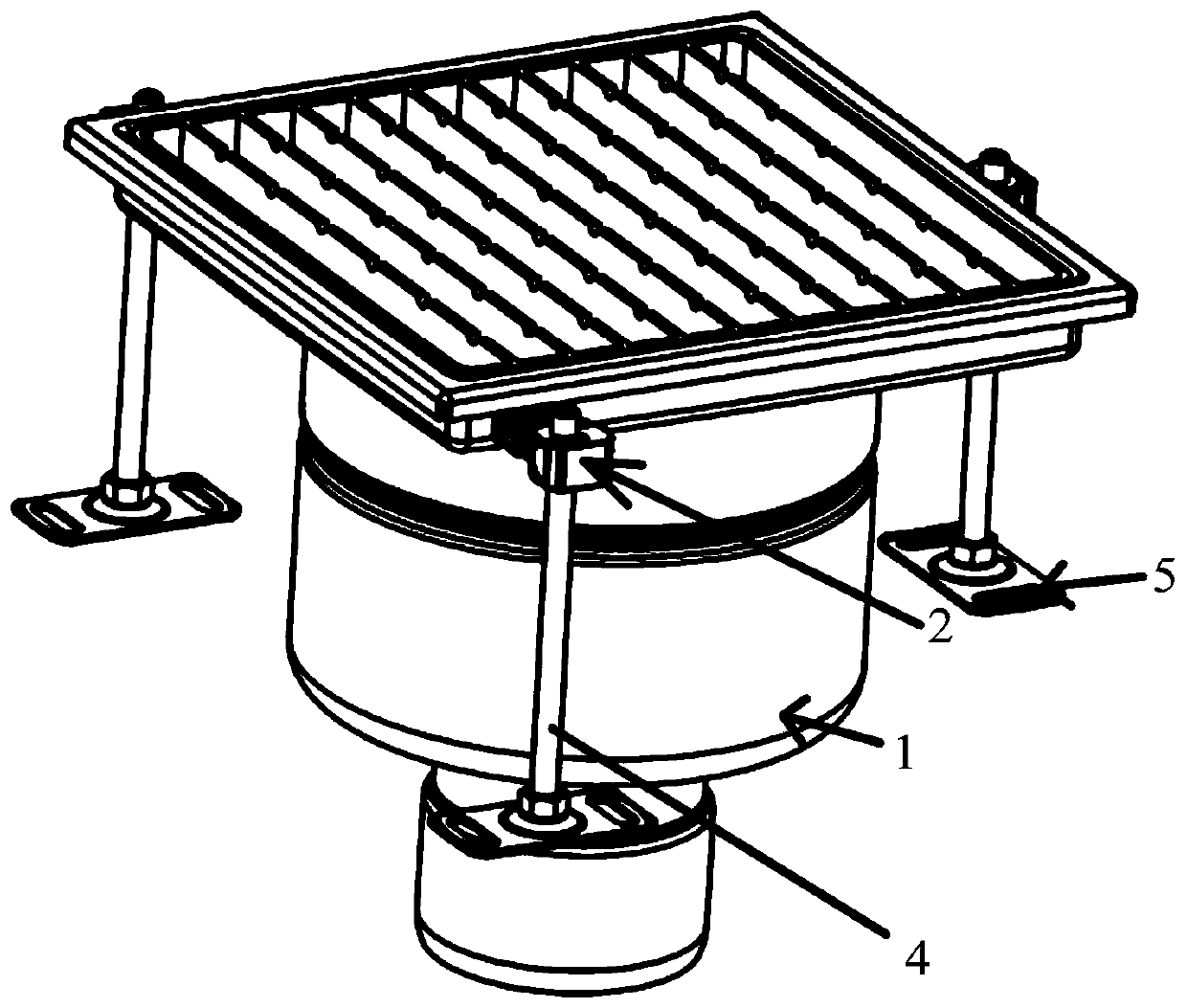

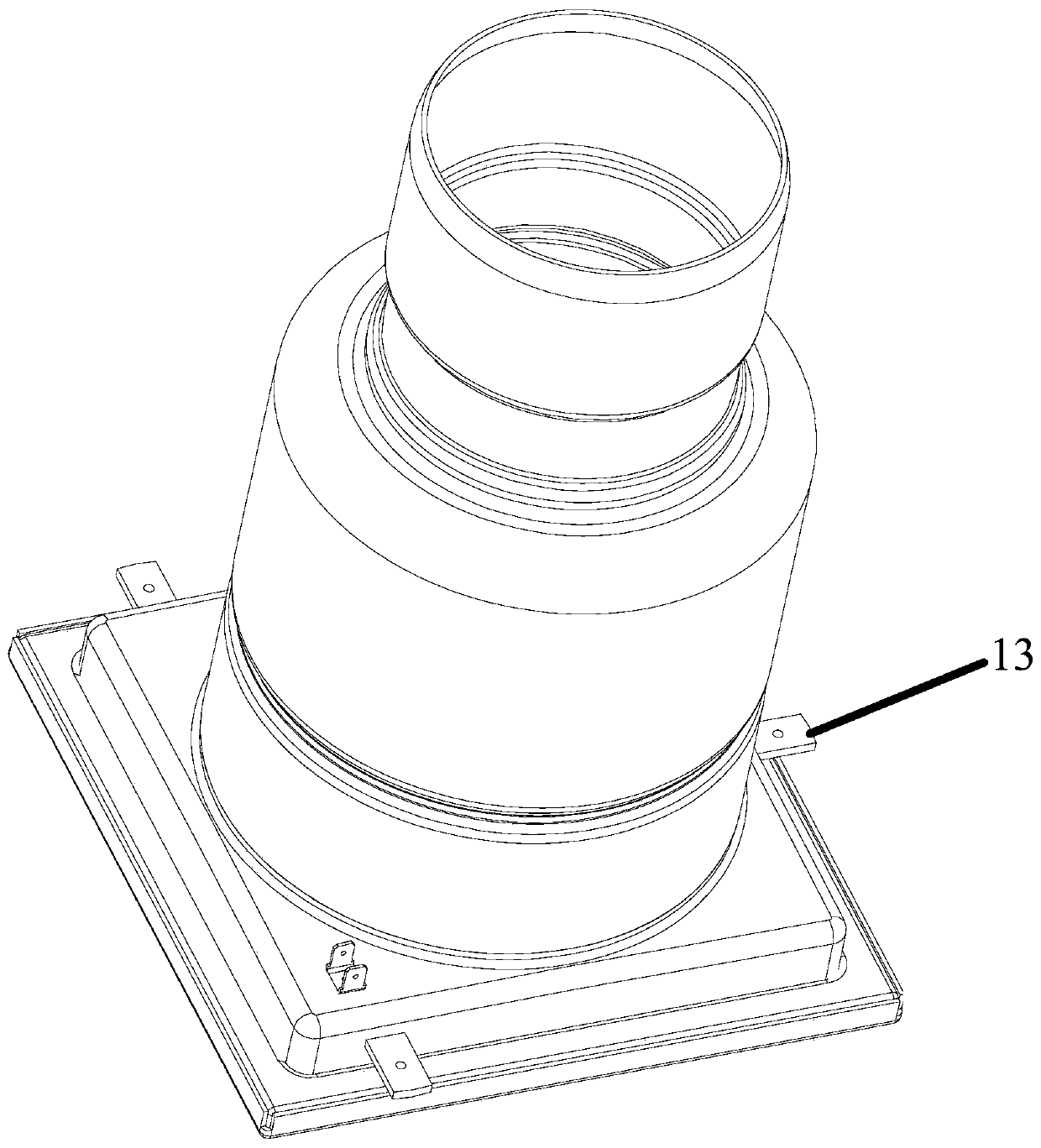

[0038] A floor drain is recorded, such as figure 1 As shown, it includes: a floor drain main body 1, and the floor drain position adjustment mechanism described above can keep the floor drain main body 1 level with the ground surface and ensure the normal drainage of the floor drain main body 1 through the setting of the above-mentioned floor drain position adjustment mechanism.

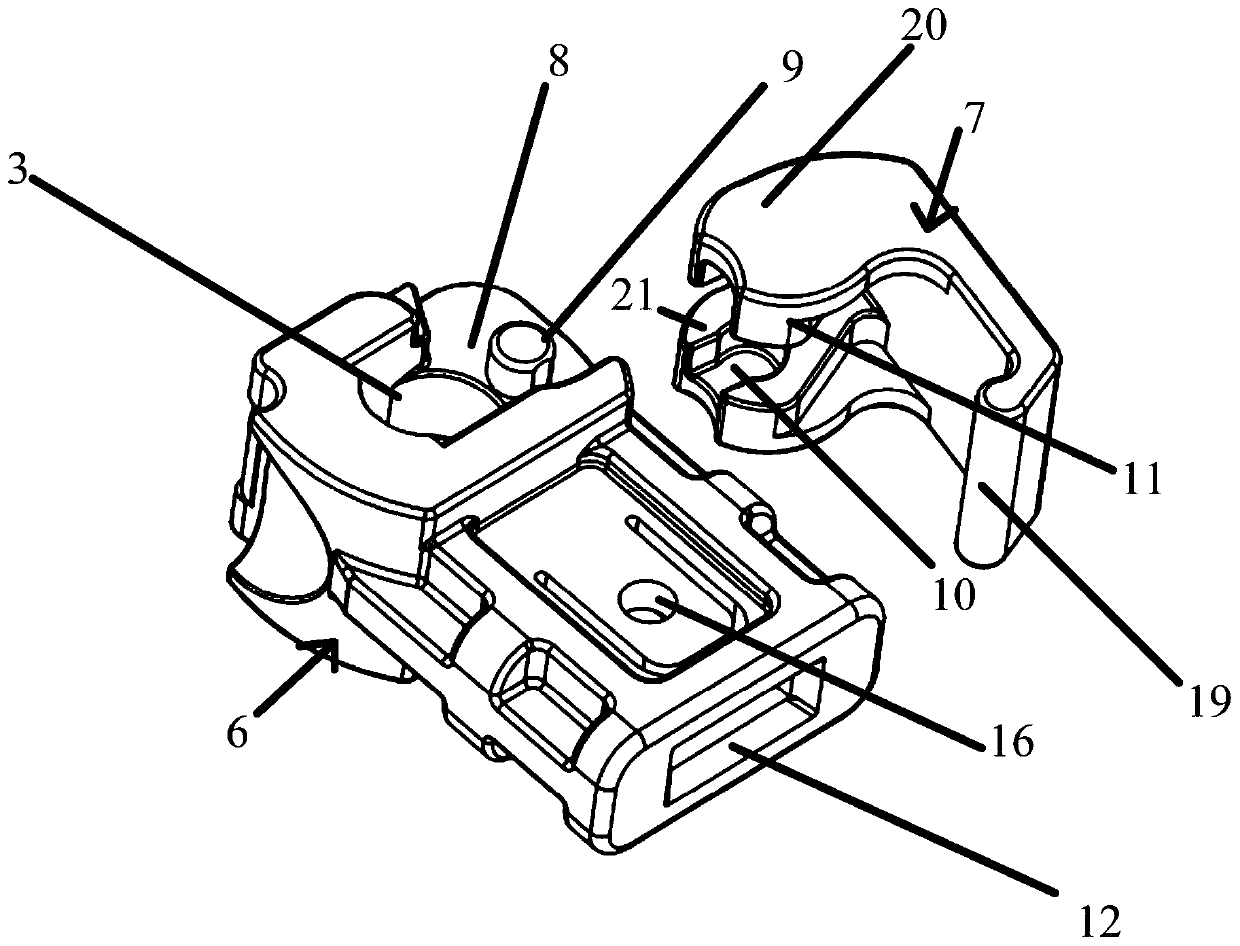

[0039] This scheme also records a floor drain position adjustment mechanism, such as figure 2 As shown, it includes: a positioning structure 2, which is connected to the main body of the floor drain 1; a support member 4, which is rod-shaped, and the positioning structure 2 is connected to the accommodating cavity for accommodating the main body 1 of the floor drain. The structure 2 is slidably arranged in the length direction of the support 4, and the positioning structure 2 has a positioning state fixedly connected to the support 4, and a sliding state slidingly connected to the support 4. In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com