Pipeline fixing device on building construction scaffold

A technology for building construction and fixing devices, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of wasting physical strength of workers, falling off of pipe clamps, physical energy consumption and increased difficulty of operation, etc., so as to achieve easy fixing, The effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

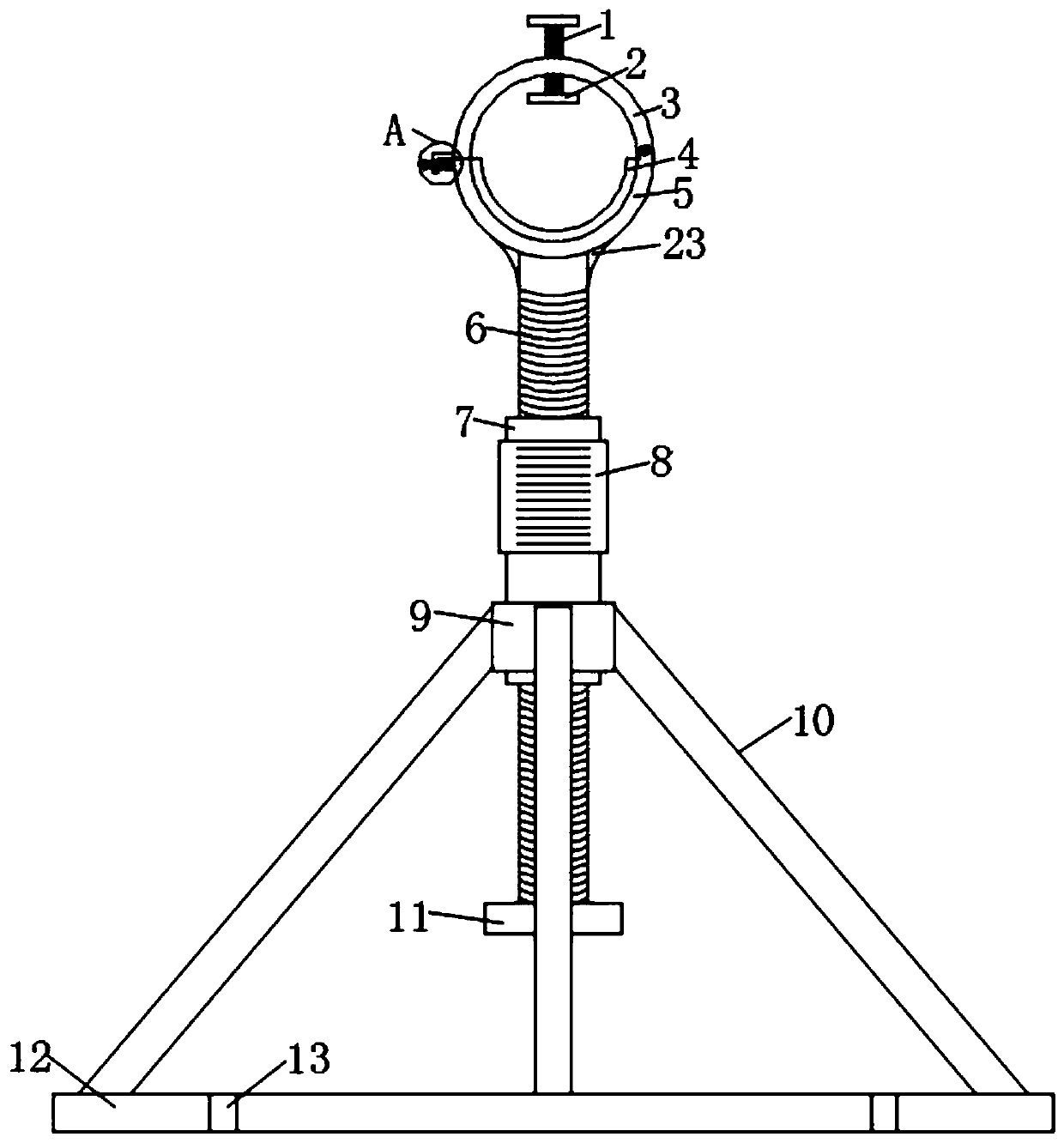

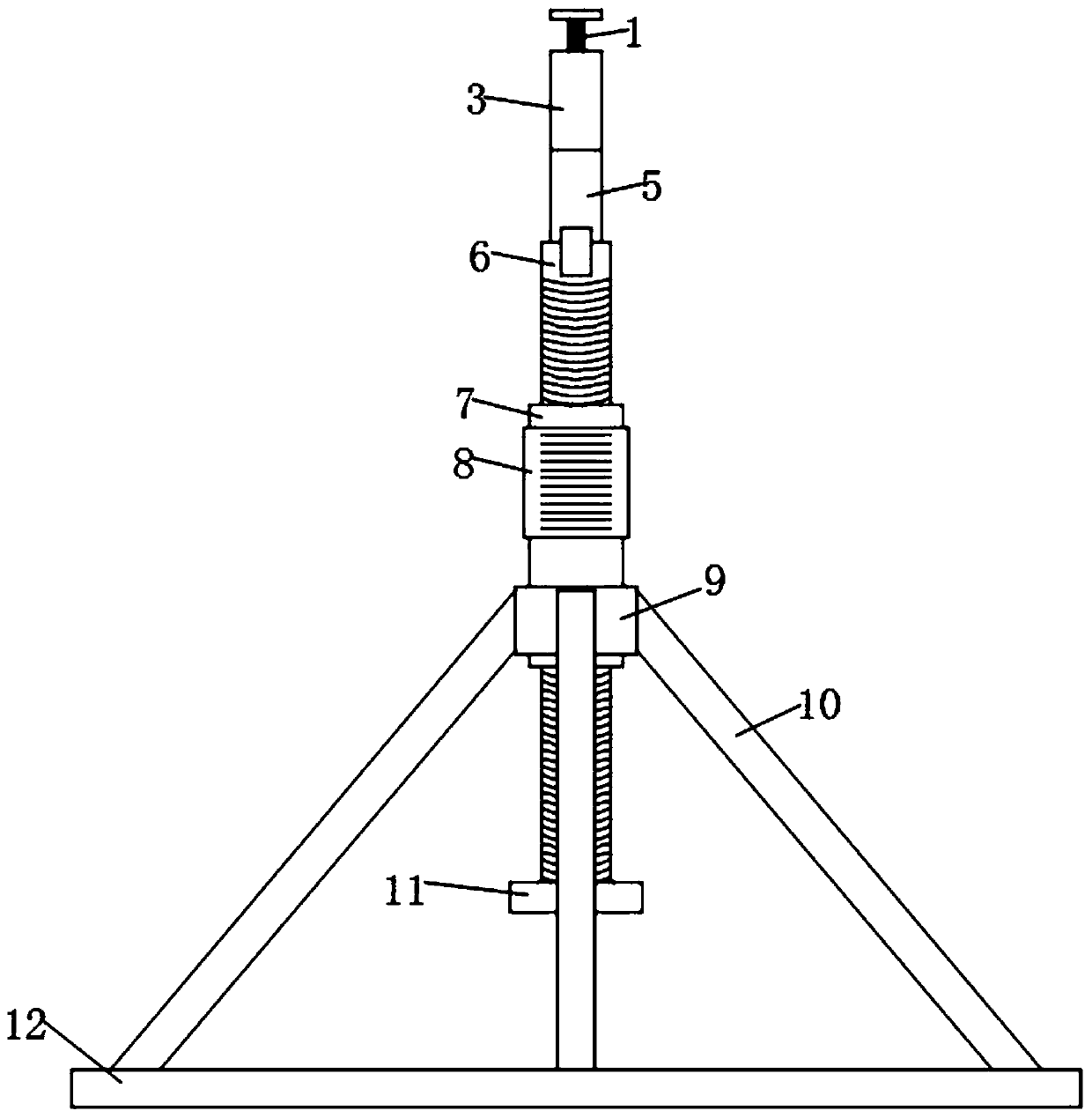

[0021] refer to Figure 1-3 , a pipeline fixing device on a building construction frame, comprising a bottom plate 12, threaded fixing holes 13 are provided around the bottom plate 12, the threaded fixing holes 13 are fixedly connected on the building construction frame by bolts, and inclined supports are fixedly connected around the bottom plate 12 Rod 10, the upper end of the inclined support rod 10 is connected to the support column 6 through the adjustment structure, the upper end of the support column 6 is welded with the lower limit ring 5, and the reinforcement rib 23 is welded between the lower limit ring 5 and the support column 6, the design of the reinforcement rib 23, The fixing effect between the lower limit ring 5 and the support column 6 is enhanced, and the lower limit ring 5 is prevented from falling off.

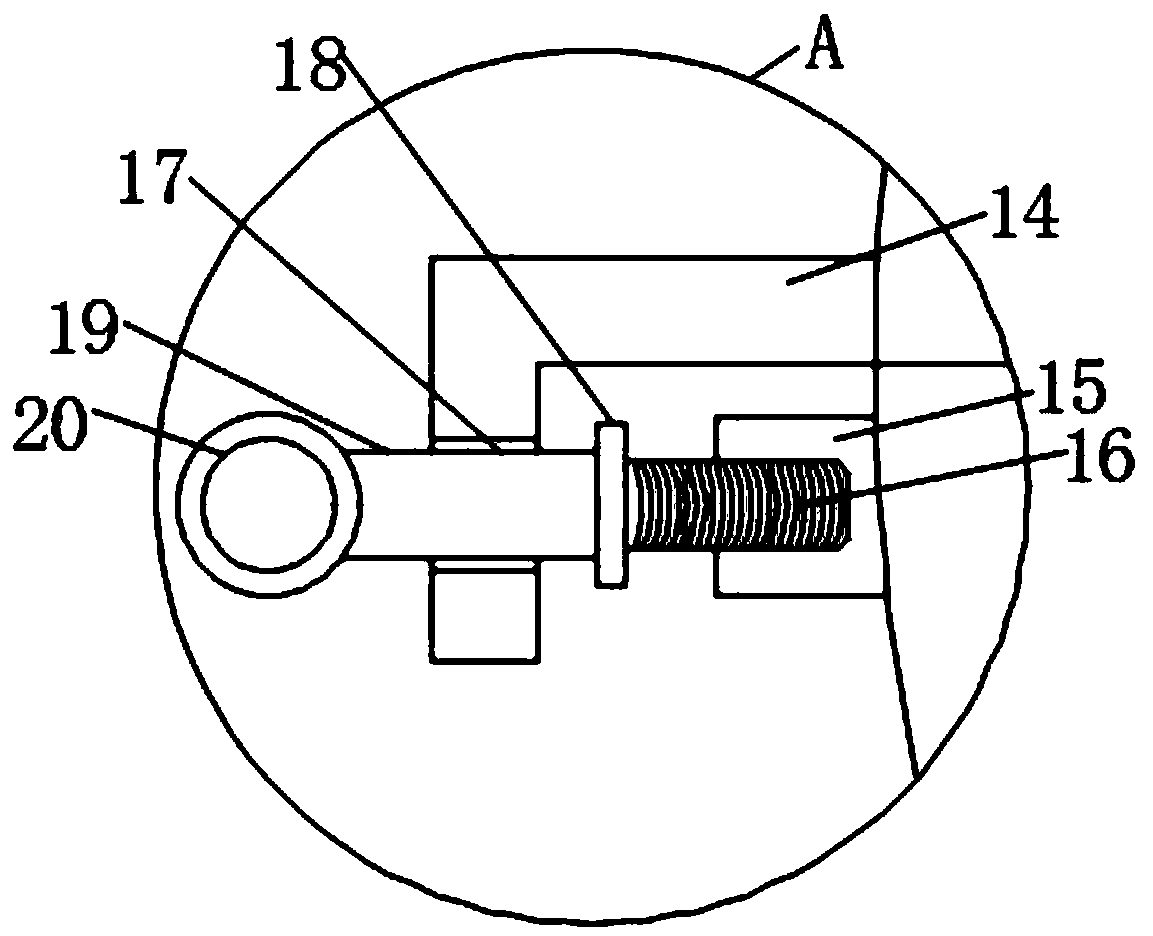

[0022] One end of the lower limit ring 5 is hinged with an upper limit ring 3, and the other end of the upper limit ring 3 is fixedly connected with an L-s...

Embodiment 2

[0026] refer to Figure 1-3 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the adjustment structure includes a bearing 9 fixedly connected to the upper end of the inclined support rod 10, the inner shaft surface of the bearing 9 is fixedly connected with a threaded sleeve 7, and the support column 6 It is provided with external threads, the support column 6 is threadedly connected with the threaded sleeve 7, and the outer side of the threaded sleeve 7 is fixedly bonded with a gripping sleeve 8, and the outer side of the gripping sleeve 8 is provided with anti-slip lines, and the gripping sleeve 8 is rotated by one hand, and a hand holds The support column 6 will drive the handle sleeve 8 to rotate on the support column 6, thereby adjusting the height of the support column 6, so as to ensure that when the pipeline is installed, the lower limit ring 5 plays a role in supporting the pipeline, so that the pipeline Being on the ...

Embodiment 3

[0028] refer to Figure 4 , as another preferred embodiment of the present invention, the difference from Embodiment 2 is that the handle cover 8 includes a sweat-absorbing layer 21, the inner ring of the sweat-absorbing layer 21 is fixedly bonded with an elastic layer 22, and the elastic layer 22 is fixedly bonded to the threaded sleeve 7 , the sweat-absorbing layer 21 is made of polymer water-absorbing resin, and the elastic layer 22 is made of butadiene rubber material. By the design of the sweat-absorbing layer 21, when the worker rotates the handle 8, it is convenient to absorb the sweat on the worker's hand and prevent sweat The effect of grasping is affected, and the design of the elastic layer 22 enhances the comfort when grasping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com