Edged notching board and its use in casting-on reinforcing and prodn. method thereof

A grooved plate, along the plate technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of metal container leakage, medium leakage, etc., to ensure personal safety, reasonable structure, simple manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through embodiments with reference to the accompanying drawings.

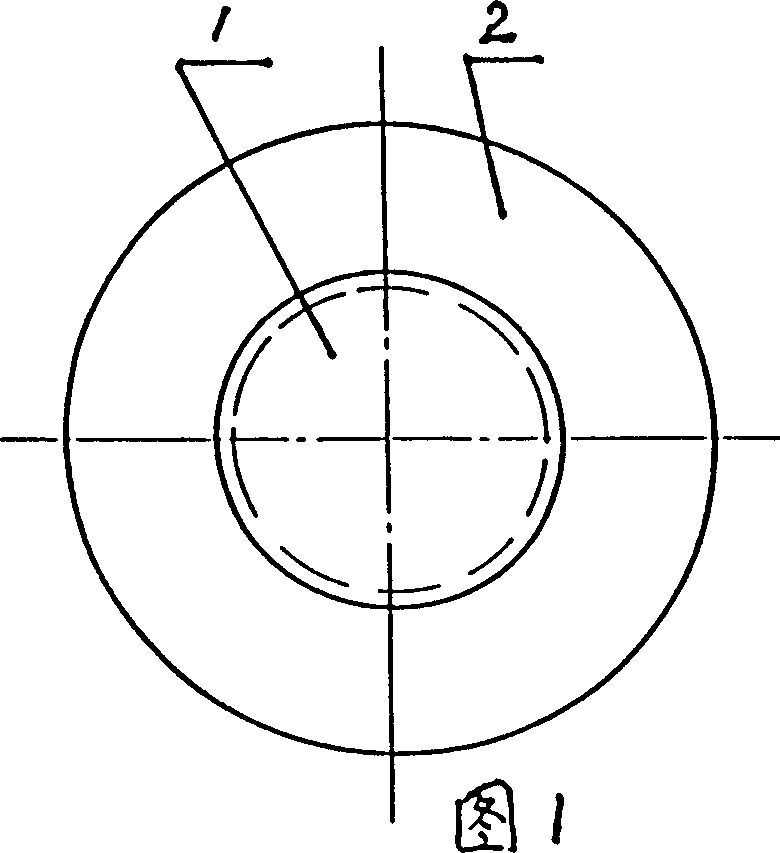

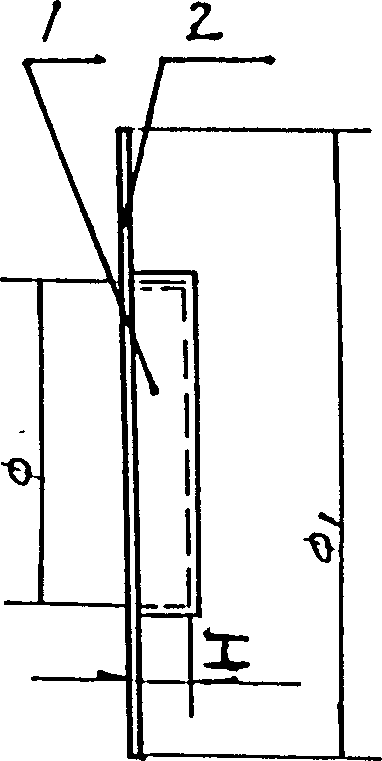

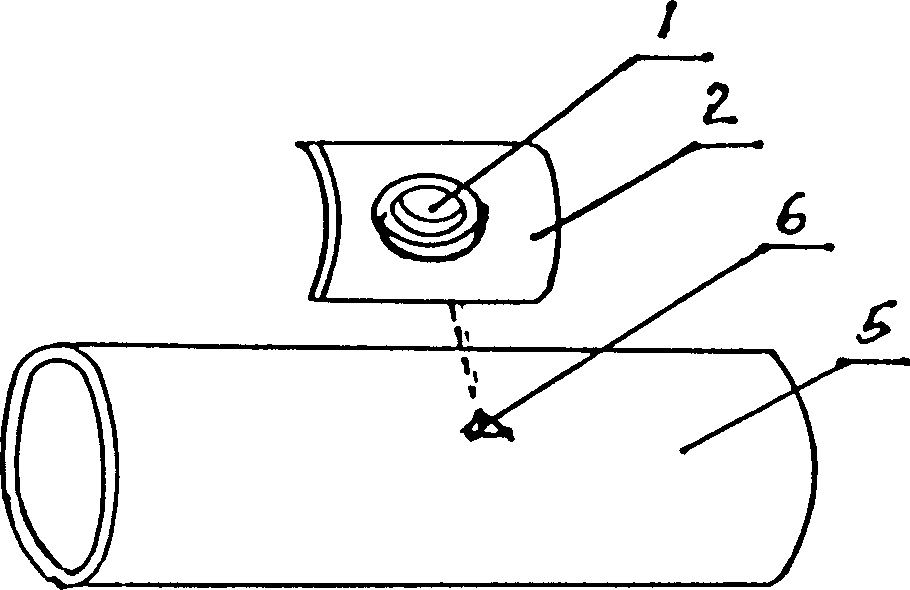

[0032] As can be seen from the accompanying drawings, there are many forms of the grooved plate designed in the present invention, which are all derived from the deformation of the most basic flat-bottomed grooved plate, and are all formed by the groove 1 in the middle and The surrounding edge plate 2 is formed, and the shape of the groove 1 can be square, cylindrical, semicircular, cone-shaped or frustum-shaped, etc., which is mainly considered in terms of structure and production. In fact, cylindrical or square Preferably, the edge plate 2 can be flat-bottomed, curved-bottomed, angular, or round-tube-shaped (i.e., inflated and pipe-segment-shaped), etc. The reason why the shape of the edge plate 2 is changed is to make it consistent with the surrounding area of the leaking point of the container. The shape of the outer surface is consistent, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com